Brake disc protective cover and brake disc assembly

A technology for a protective cover and a brake disc, applied in the field of auto parts, can solve the problems of weak structural strength of flat surface parts, aggravated friction lining loss, easy to cause deformation, etc., and achieves good heat dissipation effect and improves heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

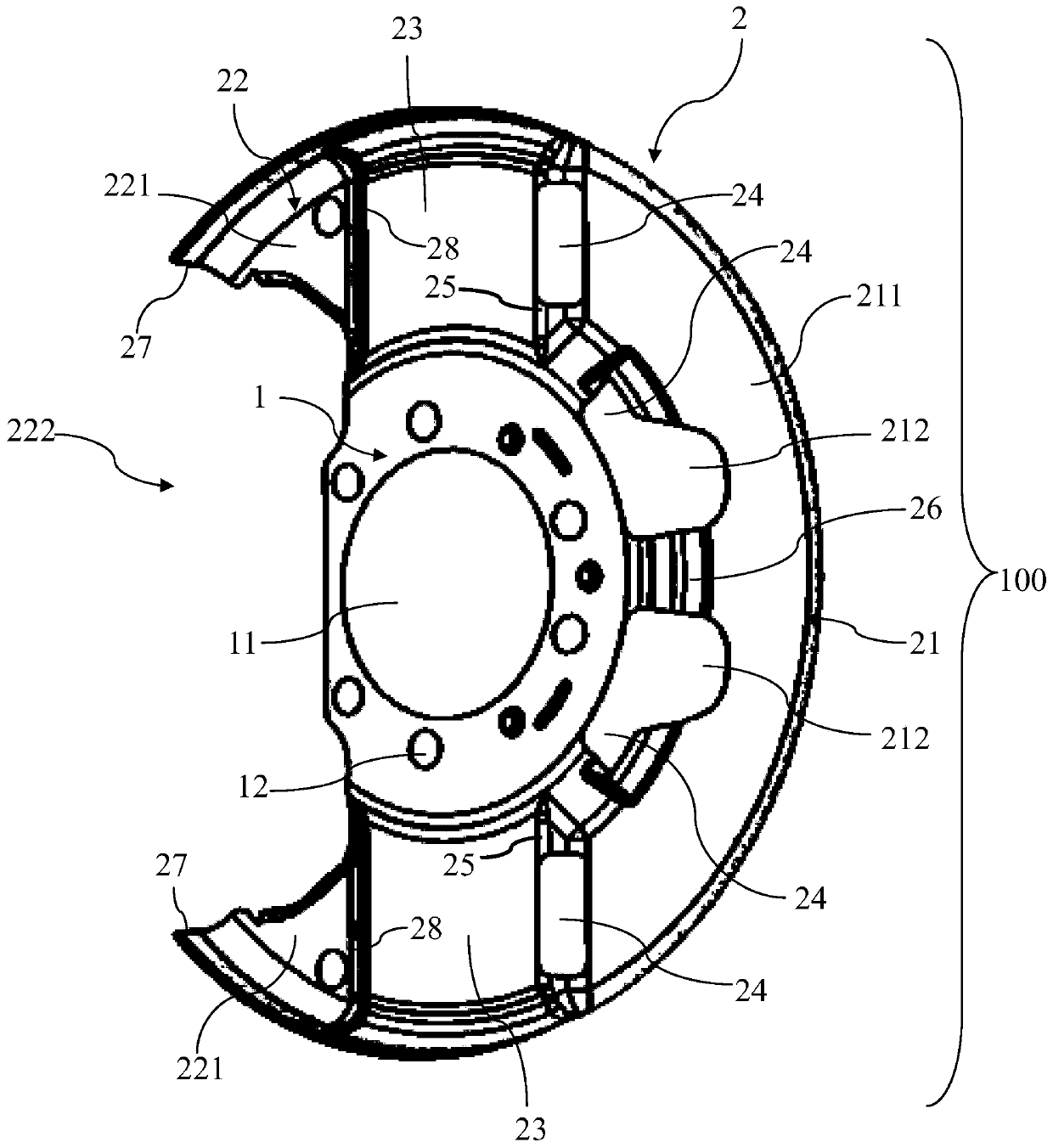

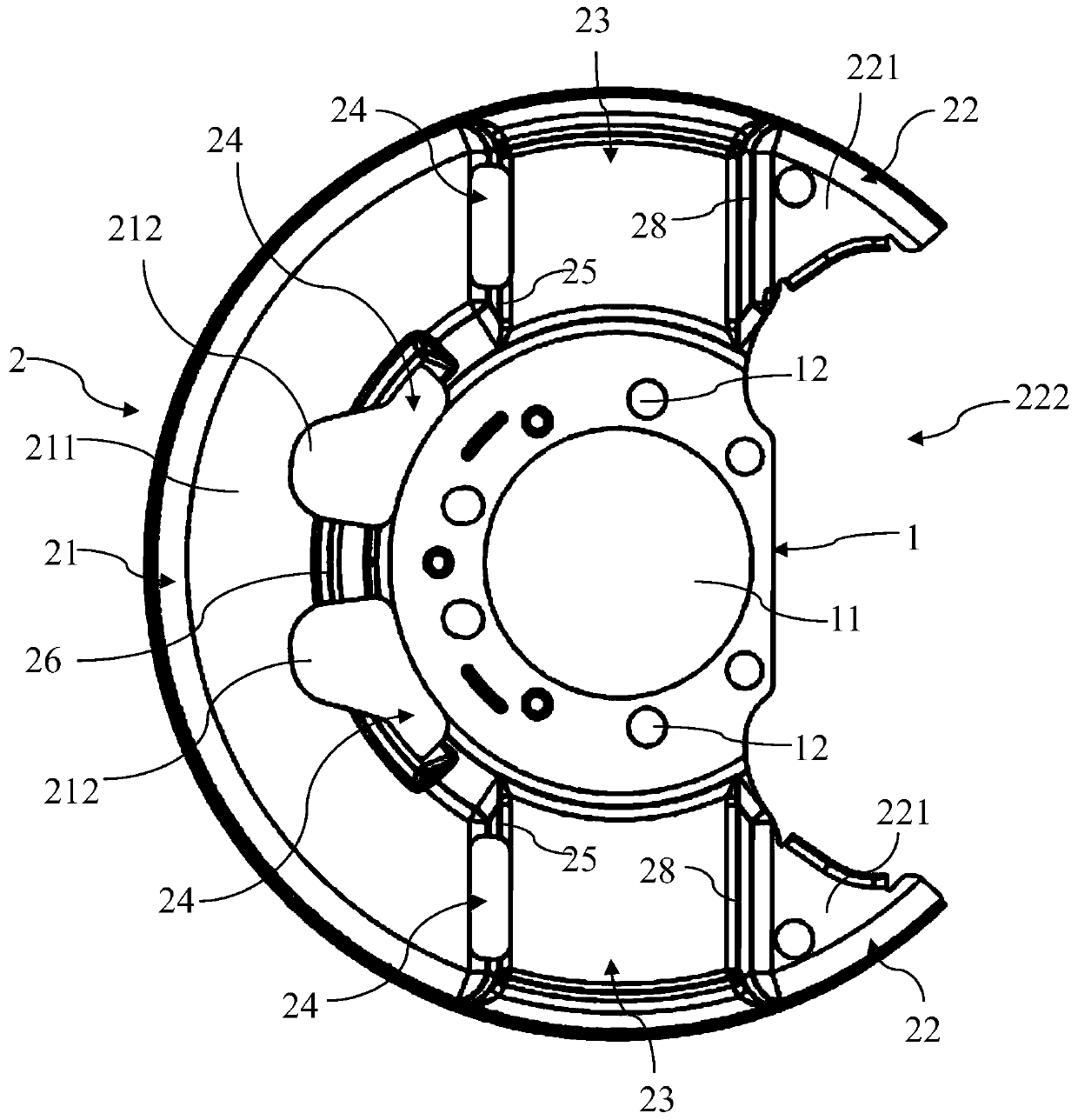

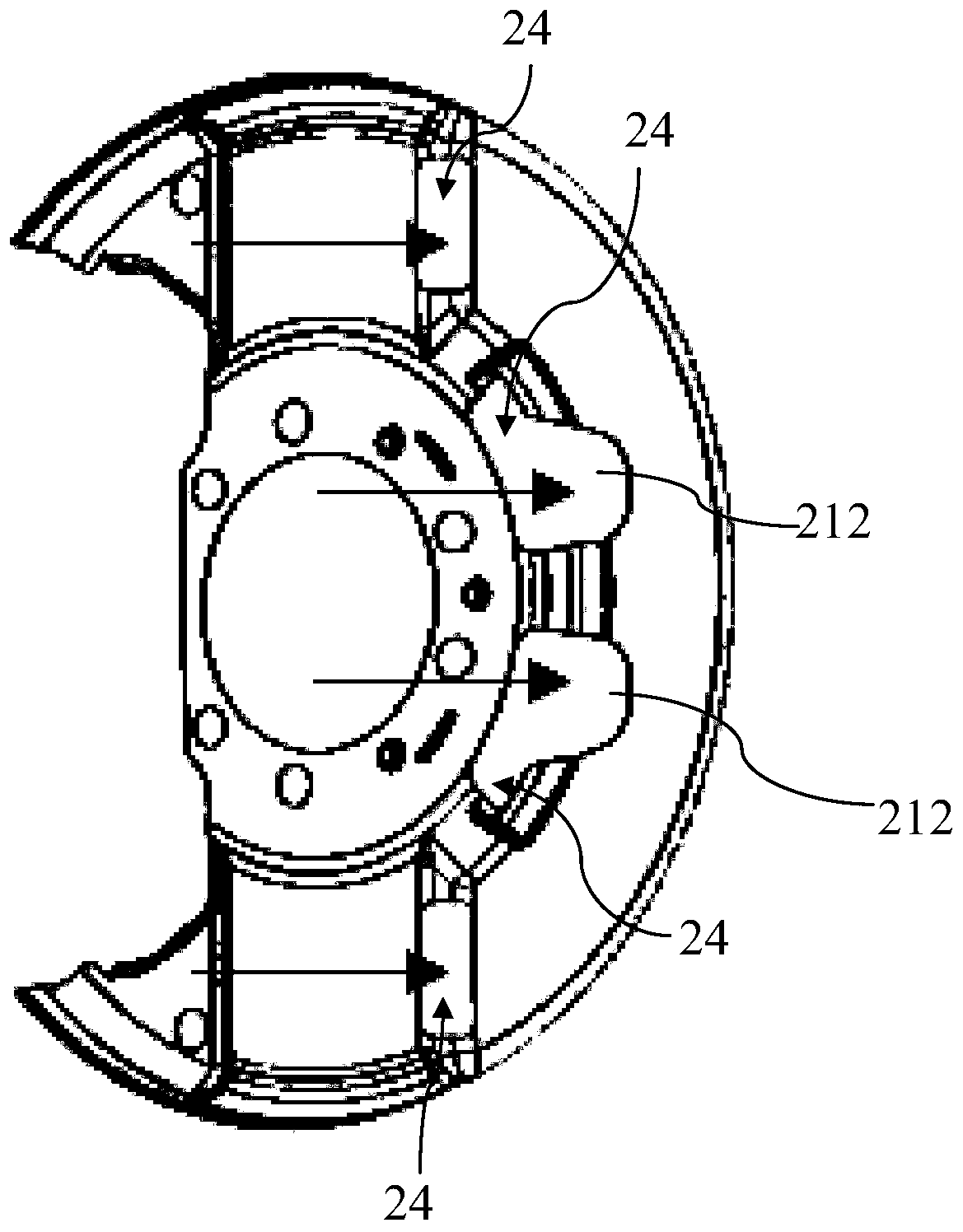

[0041] The specific implementation manner of the present application will be further described below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0042] The "inner" involved in this application refers to the direction in which the brake disc guard faces the middle of the vehicle during installation, and the "outer" involved in this application refers to the direction in which the brake disc guard faces to the outside of the vehicle; The "front" involved in the above refers to the direction towards the front of the vehicle during installation, and the "rear" involved in this application refers to the direction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com