Composite vibration damping type pipe hanger

A hanger and pipe clamp technology, which is applied in the field of composite vibration-absorbing pipe hangers, can solve the problems that the connecting rod cannot withstand large-scale vibration or impact, the service life of rubber is limited, and it is difficult to meet the vibration reduction requirements of cruise ships. Novelty, stable structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

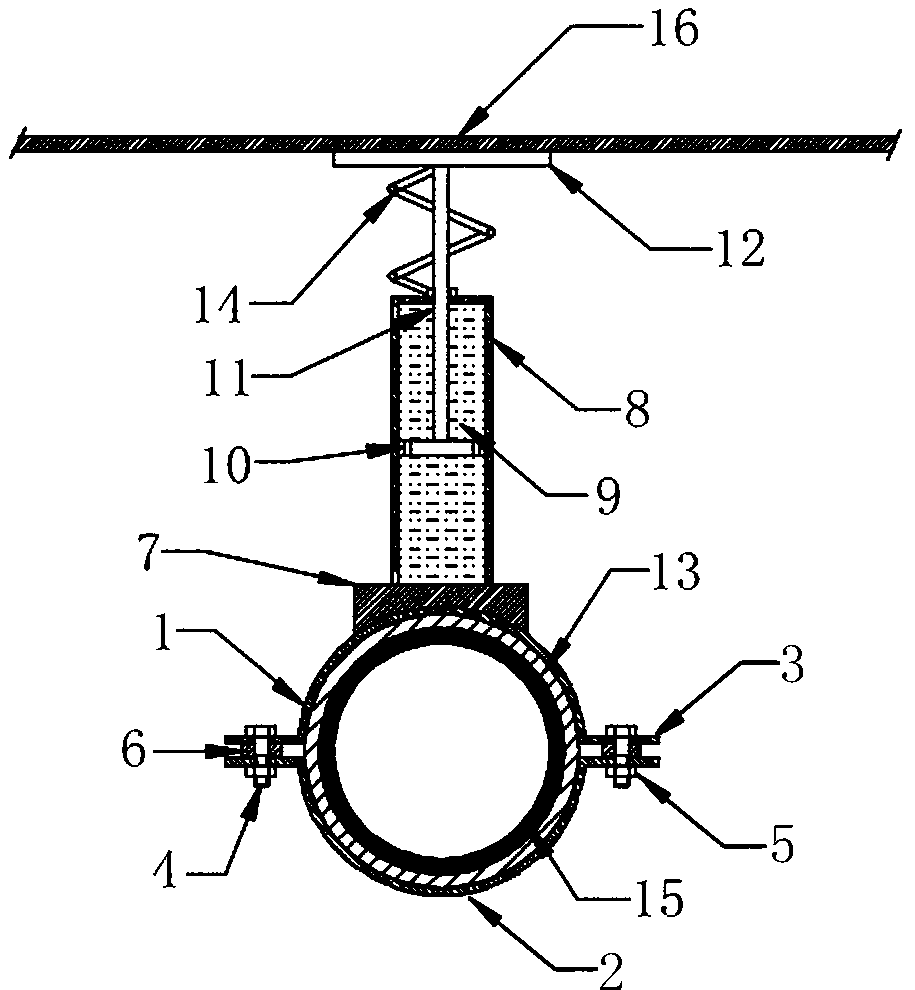

[0019] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

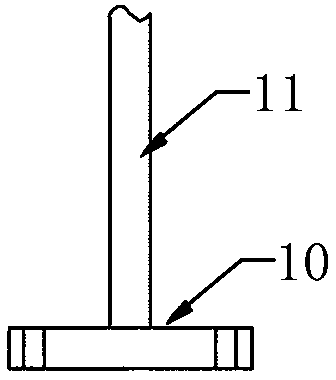

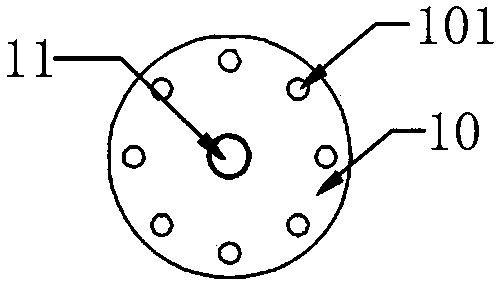

[0020] Such as figure 1 As shown, a composite damping type pipe hanger includes a semicircular upper pipe clamp body 1 and a semicircular lower pipe clamp body 2. The upper pipe clamp body 1 and the lower pipe clamp body 2 enclose a pipe containing a pipe 15 Clamping hole, both ends of the upper pipe clamp body 1 and the lower pipe clamp body 2 have clamping ends 3 extending radially outwards, and the upper pipe clamp body 1 and the lower pipe clamp body 2 are provided at the clamping ends 3 The bolt 4 is connected with the nut 5, a washer 6 is also provided between the clamping end 3 of the upper pipe clamp body 1 and the lower pipe clamp body 2, a base 7 is provided on the top of the upper pipe clamp body 1, and the base 7 is fixed An oil cylinder 8 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com