mpo fiber optic connector

An optical fiber connector and inner housing technology, which is applied in the field of MPO optical fiber connectors, can solve the problems such as the connection failure of the optical fiber connector, and achieve the effect of solving the loosening of the hook

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

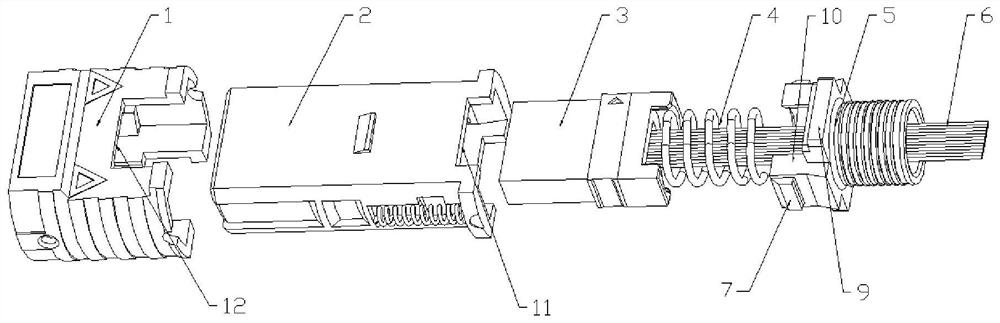

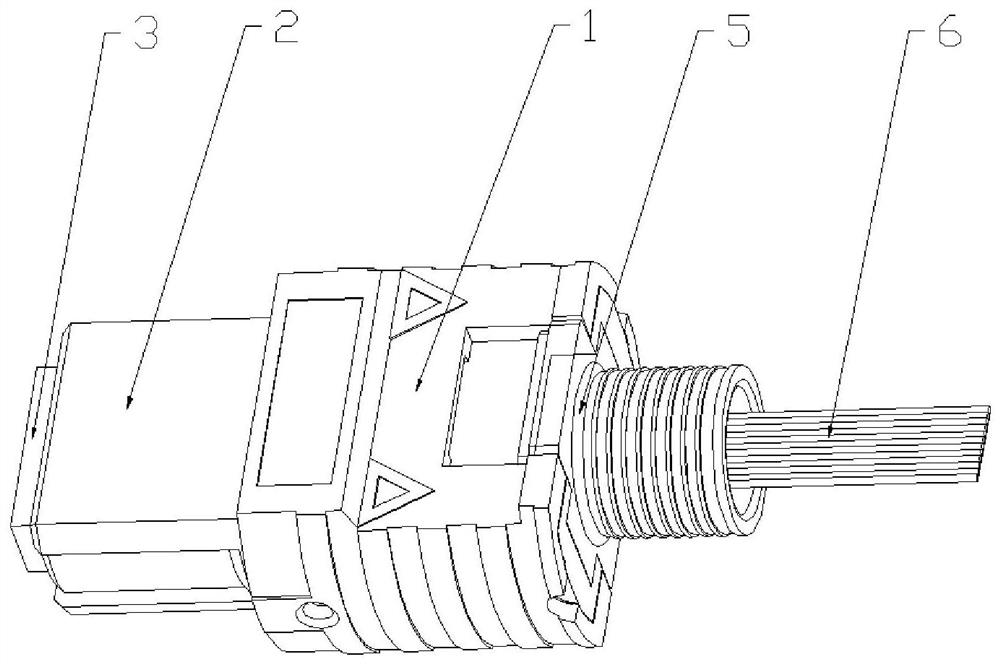

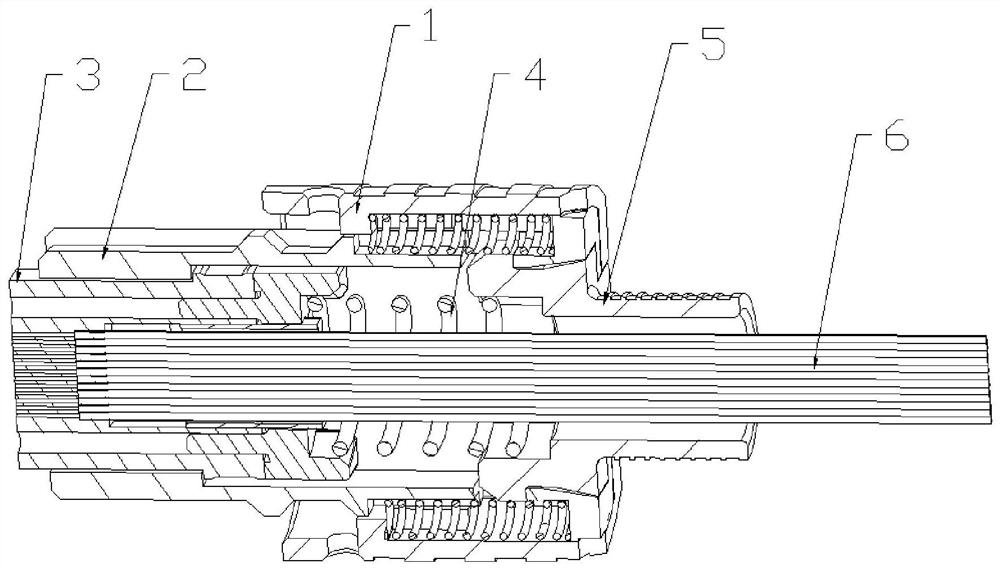

[0020] Embodiments of the MPO fiber optic connector of the present invention are as follows Figure 1 to Figure 3 As shown, it includes an outer shell 1 and an inner shell 2 that make up the outer shell assembly. The inner shell 2 has an inner cavity extending along the front and rear directions. The cross section of the inner shell 2 is rectangular, and the long side direction defining the rectangle is the MPO optical fiber In the left and right direction of the connector, there is a ferrule 3 and a spring 4 for pushing the ferrule 3 in the inner cavity. A locking protrusion 7 protruding from the protruding arm 10 is provided, and the locking protrusion 7 forms a locking structure with the groove 8 on the inner housing 2 .

[0021] The concrete structure of spring limit seat 5 is as Figure 4 As shown, the spring limit seat 5 includes a limit seat body, the limit seat body is composed of a base part and convex arms 10 on the left and right sides of the base part, and the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com