Shelf scheduling method and device, electronic equipment and warehouse management system

A technology of electronic equipment and scheduling method, applied in data processing applications, instruments, calculations, etc., can solve problems affecting order generation efficiency, uneven site busyness, etc., and achieve the effect of improving generation efficiency and average busyness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

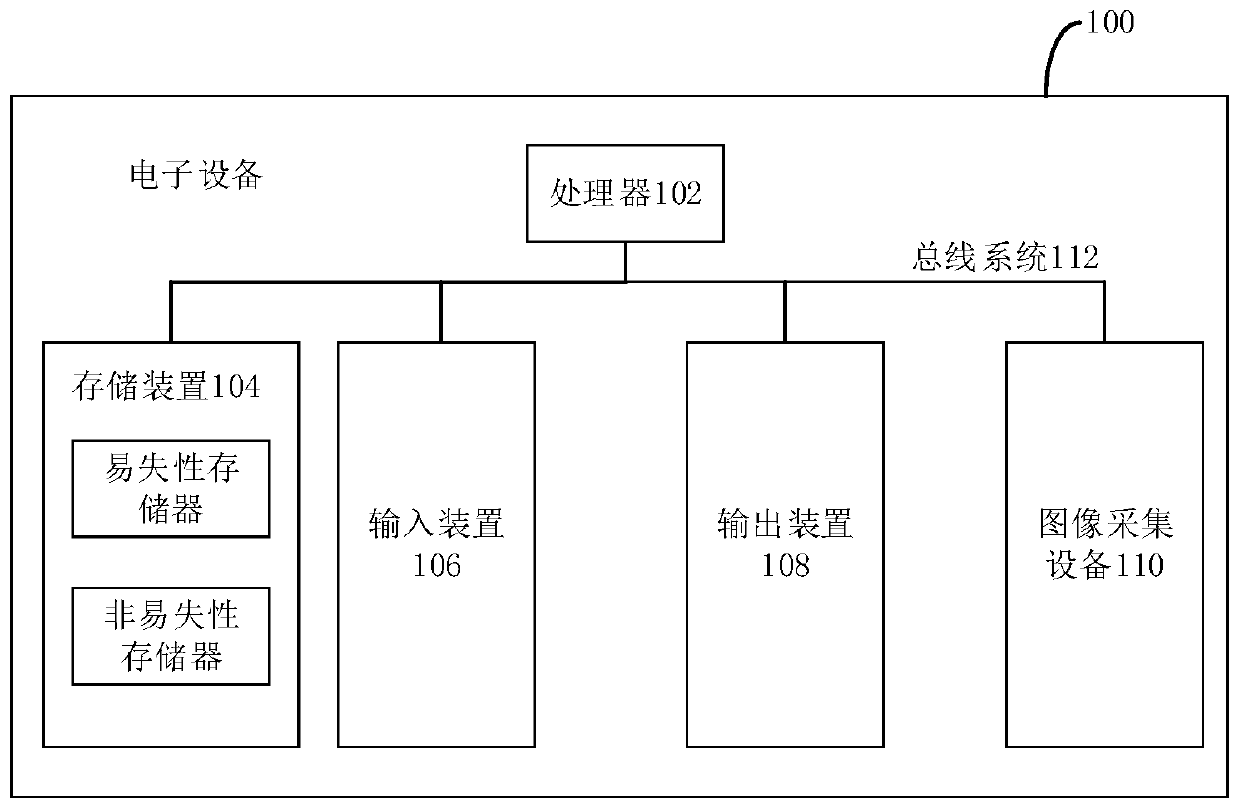

[0044] First, refer to figure 1 An example electronic device 100 for implementing the shelf scheduling method, device, electronic device and warehouse management system of the embodiments of the present invention will be described.

[0045] Such as figure 1 A schematic structural diagram of an electronic device is shown, the electronic device 100 includes one or more processors 102, one or more storage devices 104, an input device 106, an output device 108 and one or more image acquisition devices 110, these components The interconnections are via bus system 112 and / or other forms of connection mechanisms (not shown). It should be noted that figure 1 The components and structure of the electronic device 100 shown are only exemplary and not limiting. According to needs, the electronic device may also have other components and structures, or the electronic device may also have fewer components than those shown in the figure. Alternatively, the electronic device can also have ...

Embodiment 2

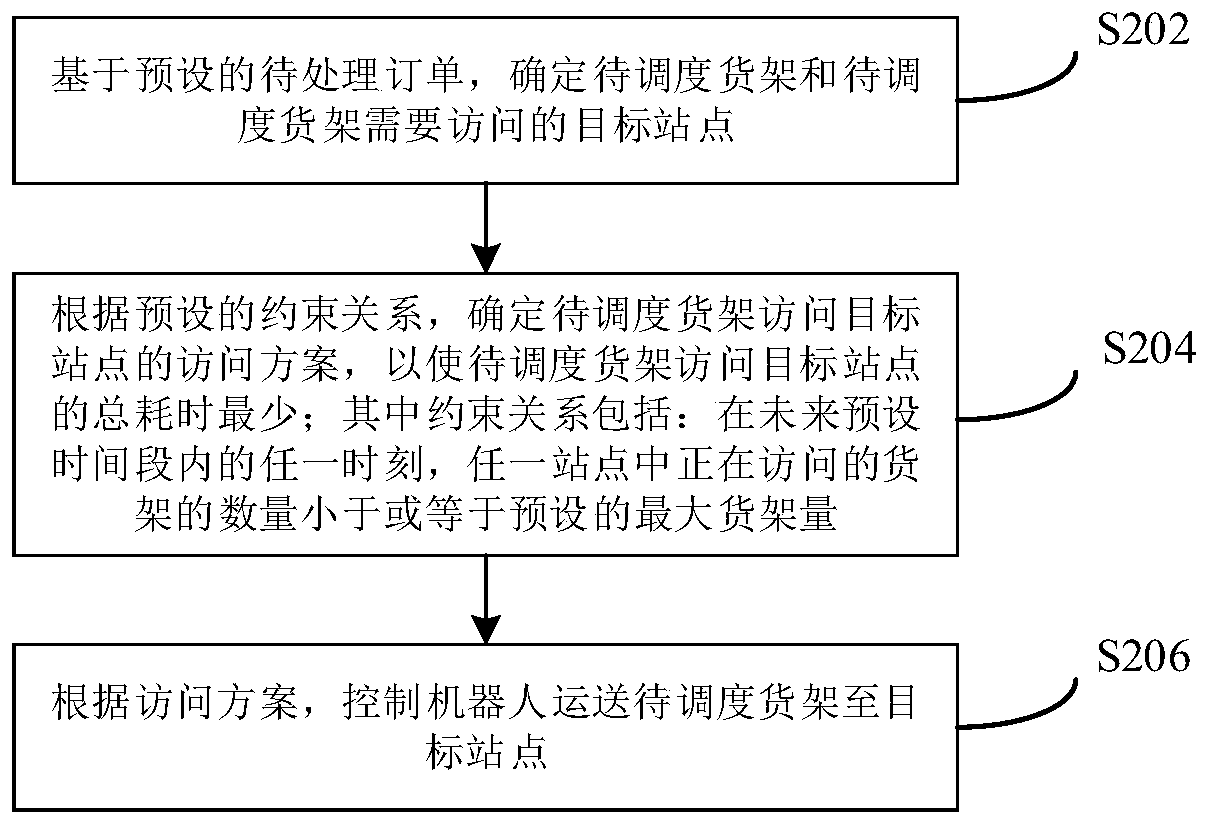

[0053] This embodiment provides a shelf scheduling method, which can be applied to the above-mentioned electronic equipment; the electronic equipment communicates with the robot; the robot is used to transport the shelves to the target site; figure 2 As shown, the method includes the following steps:

[0054] Step S202, based on the preset order to be processed, determine the shelf to be dispatched and the target site that the shelf to be dispatched needs to visit;

[0055] The above preset pending orders can be orders sent by users using computers, tablets, mobile phones or wearable devices through web pages, shopping apps and other applications; they can also be orders entered manually in large quantities, such as bulk goods orders etc.; it can also be an order generated by the control system of the warehouse or workshop to meet the materials or parts required by a certain production link.

[0056] The number of orders to be processed is often multiple; for example, the wa...

Embodiment 3

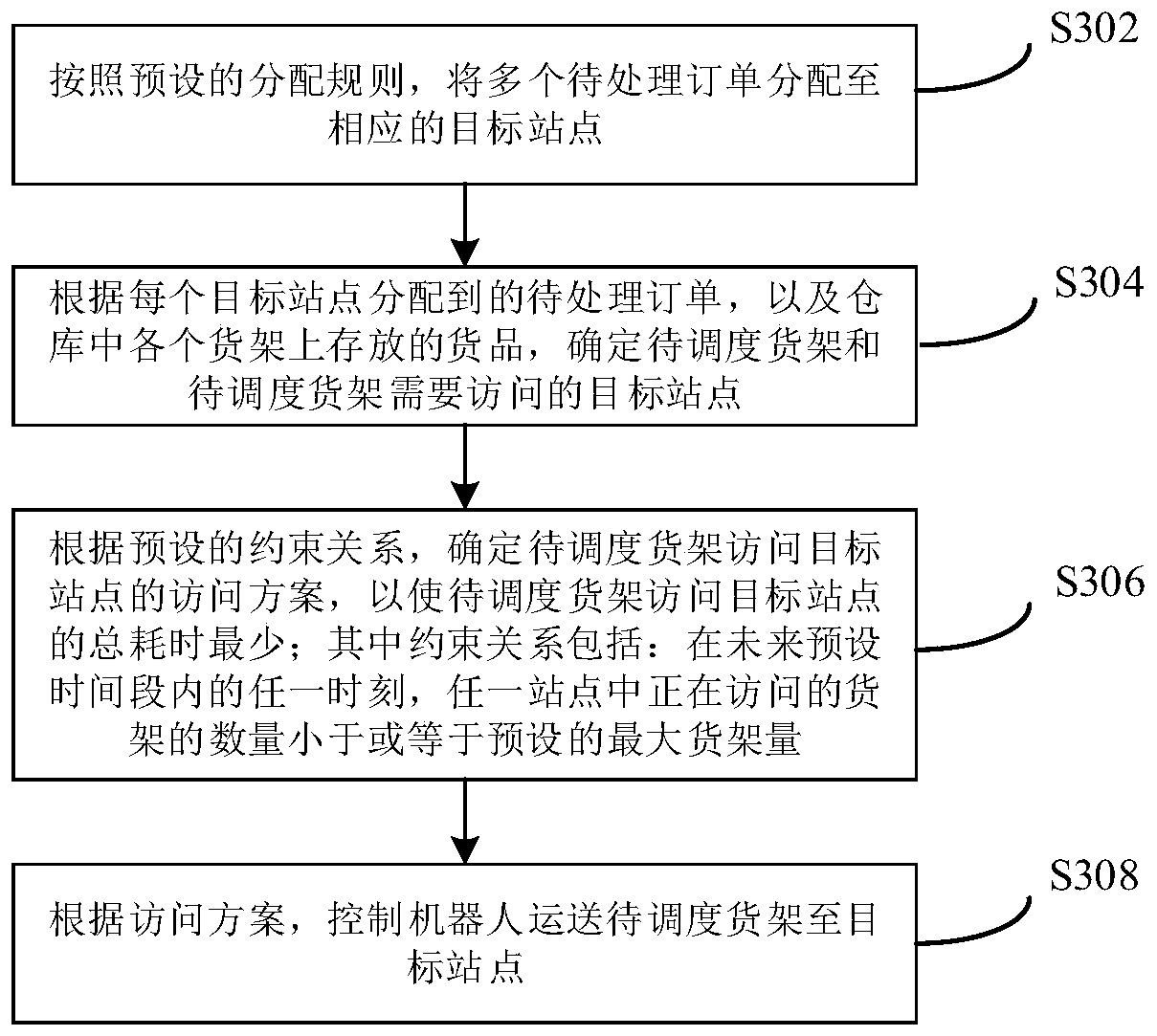

[0066] This embodiment provides another shelf scheduling method, which is implemented on the basis of the above-mentioned embodiments; this embodiment focuses on determining the shelf to be dispatched and the target site that the shelf to be dispatched needs to visit based on the preset order to be processed Specific process; in this embodiment, there are multiple orders to be processed, and multiple target sites. Such as image 3 As shown, the shelf scheduling method of this embodiment includes the following steps:

[0067] Step S302, assigning multiple pending orders to corresponding target sites according to preset assignment rules;

[0068] The above-mentioned preset allocation principle can be the allocation of orders to be processed within a certain period of time. The time can be 5 minutes, 10 minutes, 1 hour, half a day or a day, and can be allocated by the warehouse system or manually. The allocation principle can be determined according to the busyness of the curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com