Taxus chinensis antibacterial socks and manufacturing method thereof

A production method and technology of yew, applied in the directions of socks, pantyhose, biochemical fiber treatment, etc., can solve the problems of poor antibacterial durability and disappearance of antibacterial effect, and achieve the effect of enhanced antibacterial effect, significant antibacterial effect, and comfortable wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

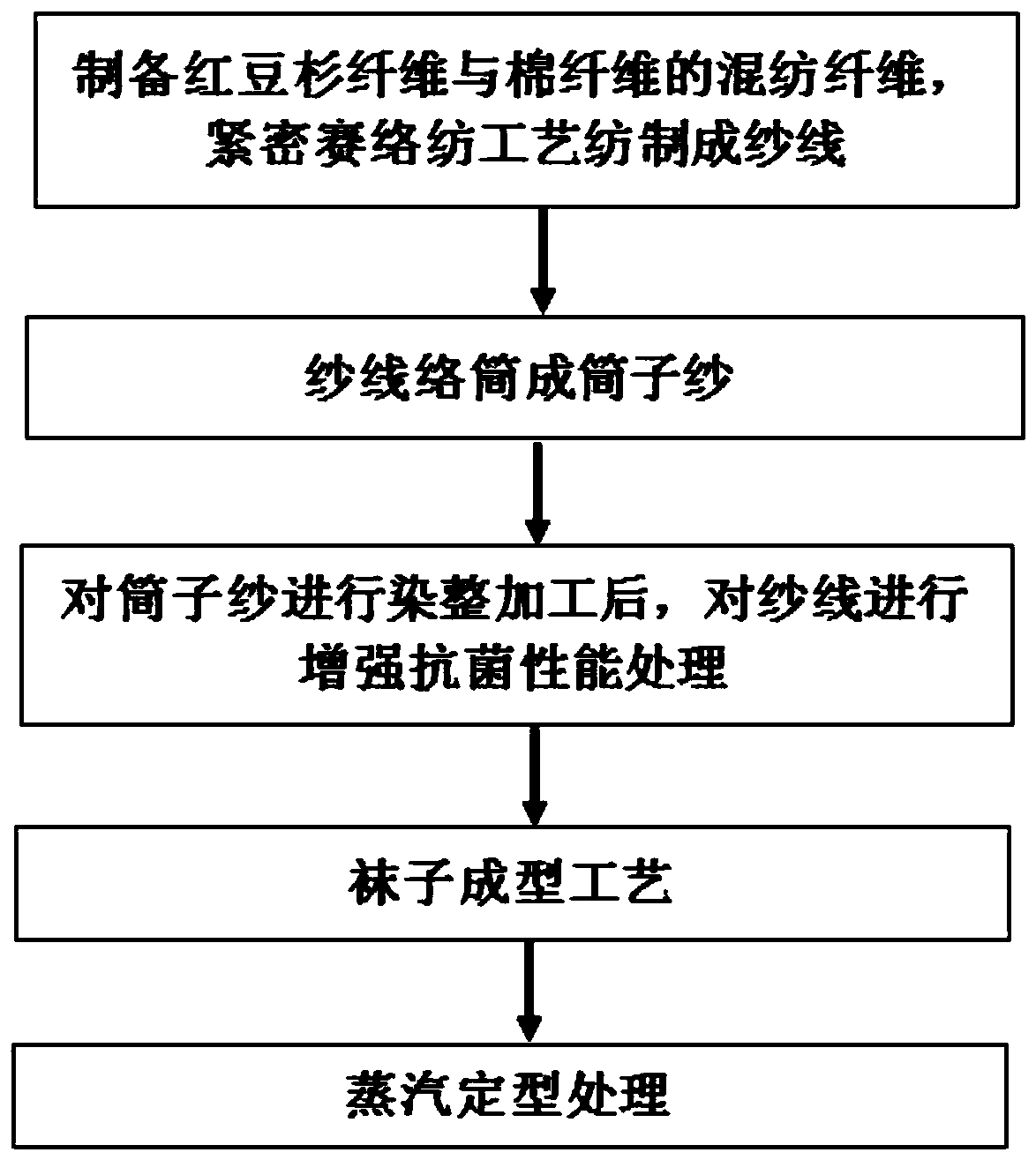

Method used

Image

Examples

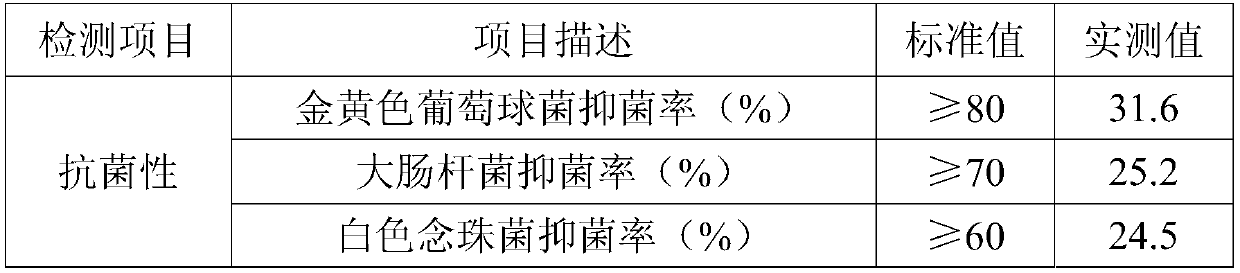

Embodiment 1

[0022] A kind of manufacture method of yew antibacterial socks, comprises the following steps:

[0023] (1) Raw materials of yew trees: the prepared raw materials are cooked to make yew pulp, and then the yew pulp is used to produce silk, which is dried and cut to form yew short fibers, and the yew short fibers are combined with Cotton fiber blending: the blended fiber of yew fiber and cotton fiber is obtained, after combing, drawing, roving, and spun yarn, it is spun into yarn by compact siro spinning process, and the finished yarn linear density is 18.5tex;

[0024] (2) winding the yarn obtained in step (1) into cheese;

[0025] (3) carry out dyeing and finishing processing to the cheese in step (2);

[0026] (4) Socks molding process: using South Korea Fusheng brand hosiery machine, the main raw material is the yarn processed in step (3), the auxiliary material is nylon / spandex covered yarn (70D / 30D), and 168N double needle cylinder is used for weaving , After getting off...

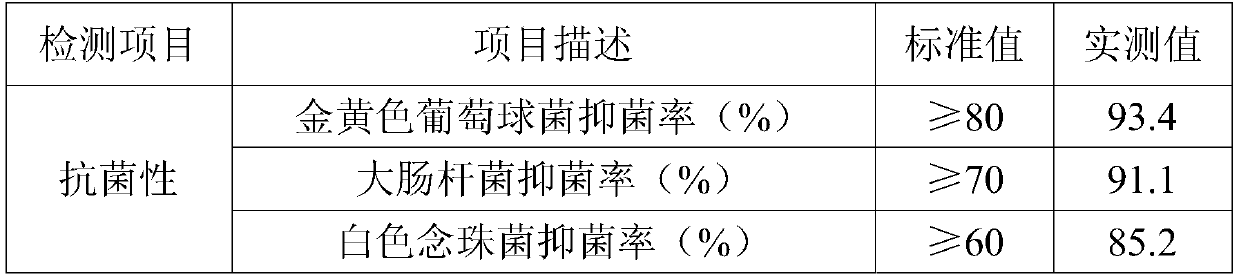

Embodiment 2

[0031] A kind of manufacture method of yew antibacterial socks, comprises the following steps:

[0032] (1) Raw material of yew trees: cook the prepared raw materials to make yew pulp, then use yew pulp to produce silk, dry and cut to form yew short fibers, and combine yew fibers with cotton Fiber blending: the blended fiber of yew fiber and cotton fiber is obtained, after combing, drawing, roving, and spun yarn, the compact siro spinning process is used to spin the yarn, and the finished yarn linear density is 18.5tex;

[0033] (2) winding the yarn obtained in step (1) into cheese;

[0034] (3) After the package yarn of step (2) is dyed and finished, adopt the Rudolf silver ion antibacterial agent RUCO-BAC AGP to carry out antibacterial performance enhancement treatment to the yarn, specifically as follows:

[0035] Use a cheese dyeing vat to soak the cheese in a treatment solution at 40°C for 20 minutes and circulate it for 20 minutes. The concentration of the Rudolph silve...

Embodiment 3

[0041] A kind of manufacture method of yew antibacterial socks, comprises the following steps:

[0042] (1) Raw material of yew trees: cook the prepared raw materials to make yew pulp, then use yew pulp to produce silk, dry and cut to form yew short fibers, and combine yew fibers with cotton Fiber blending: the blended fiber of yew fiber and cotton fiber is obtained, after carding, drawing, roving, and spun yarn, the yarn is spun into yarn by compact siro spinning process, and the finished yarn linear density is 14.8tex;

[0043] (2) winding the yarn obtained in step (1) into cheese;

[0044] (3) After the package yarn of step (2) is dyed and finished, adopt the Rudolf silver ion antibacterial agent RUCO-BAC AGP to carry out antibacterial performance enhancement treatment to the yarn, specifically as follows:

[0045] Use a cheese dyeing vat to soak the cheese in a treatment solution at 40°C for 20 minutes and circulate it for 20 minutes. The concentration of the Rudolph silv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com