Winding type semi-automatic seedling packaging machine

A semi-automatic, winding technology, used in packaging, transportation and packaging, packaging/bundling items, etc., which can solve the problems of cumbersome process, many packaging steps, loss of water balance of seedlings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

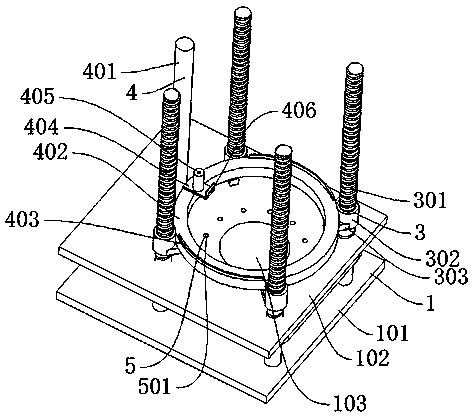

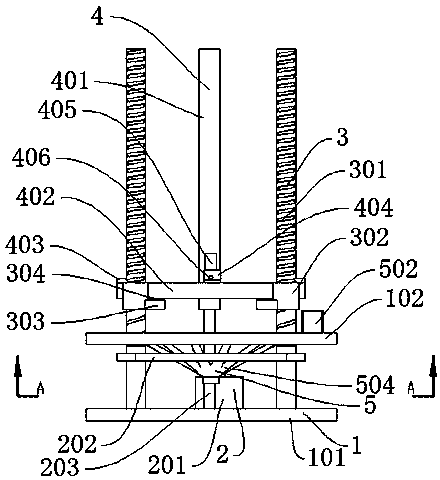

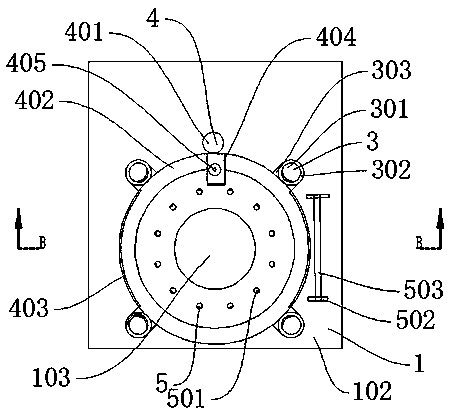

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the winding semi-automatic seedling packaging machine includes a support mechanism 1 and a power mechanism 2. The support mechanism 1 is mainly composed of a base plate 101, a support plate 102, and a pit 103. It also includes a lifting mechanism 3, a trunk packaging mechanism 4, and a root packaging mechanism. Mechanism 5, power mechanism 2 is arranged between supporting mechanism 1, lifting mechanism 3 is arranged above supporting mechanism 1, trunk packaging mechanism 4 is arranged between lifting mechanism 3, and root packaging mechanism 5 is arranged below trunk packaging mechanism 4.

[0032]The lifting mechanism 3 includes a lead screw 301, a sleeve 302, a connecting plate 303, and a ball 304. The lower end of the lead screw 301 is connected to the power mechanism 2. The lead screw 301 is used to drive the sleeve 302 to move up and down, and the outside of the lead screw 301 is thread...

Embodiment 2

[0035] Such as Image 6 with Figure 7 As shown, the difference between Embodiment 2 and Embodiment 1 is that the trunk packaging mechanism 4 includes a worm 401, a turbine 402, a lower blade 43, a fixed plate 404, a fixed rod 405, a through hole 406, and a groove 47, and the front of the worm 401 engages There is a turbine 402, and the worm 401 is used to drive the turbine 402 to rotate. The turbine 402 is arranged between the lifting mechanism 3. The turbine 402 is used to drive the fixed plate 404 to rotate around the seedlings. There are two lower blades 43 connected by screws below the turbine 402. The turbine 402 The top is connected with a fixed plate 404 by screws, and the fixed plate 404 is used to fix the fixed rod 405. The fixed plate 404 is arranged between the lower blades 43. The hole 406 prevents the hemp rope from swinging, and the lower blade 43 is used for cutting the plastic film. A groove 47 is provided directly below the lower blade 43. The groove 47 is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com