A kind of beautifying equipment after tile laying

A technology of paving and seaming, applied in the direction of construction and building structure, can solve the problems of inability to integrate operation and difficult to clean, and achieve the effect of shortening the construction period and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

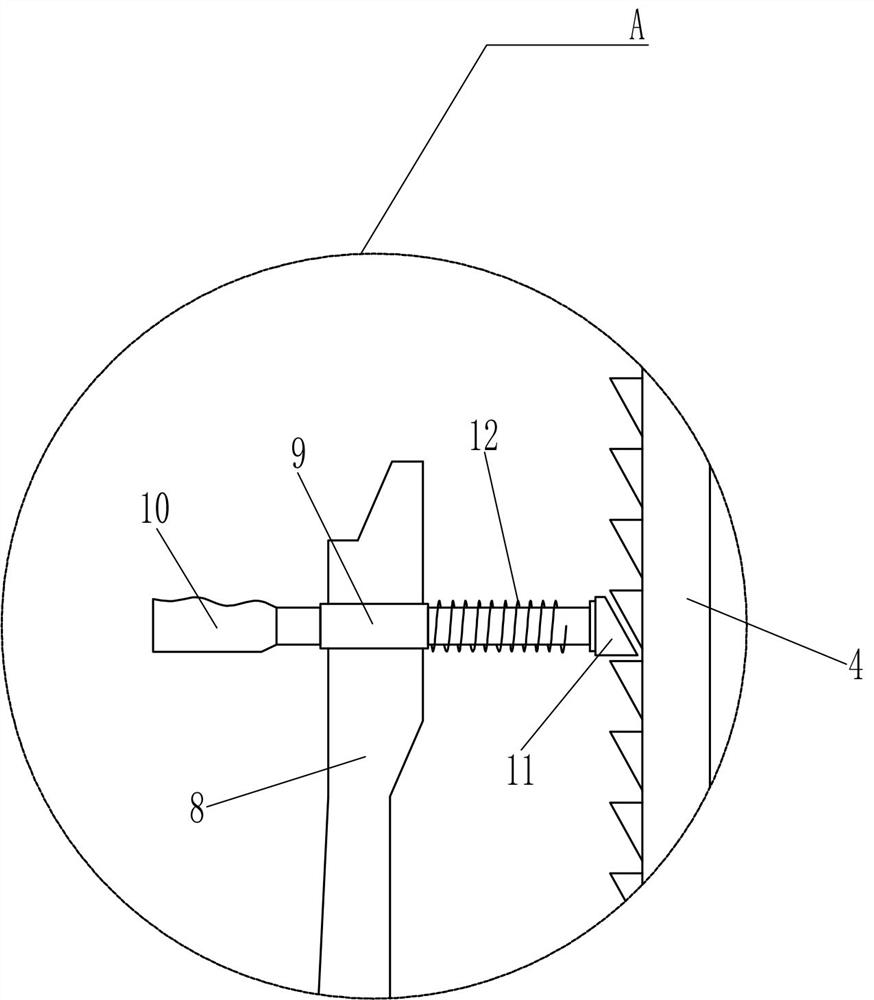

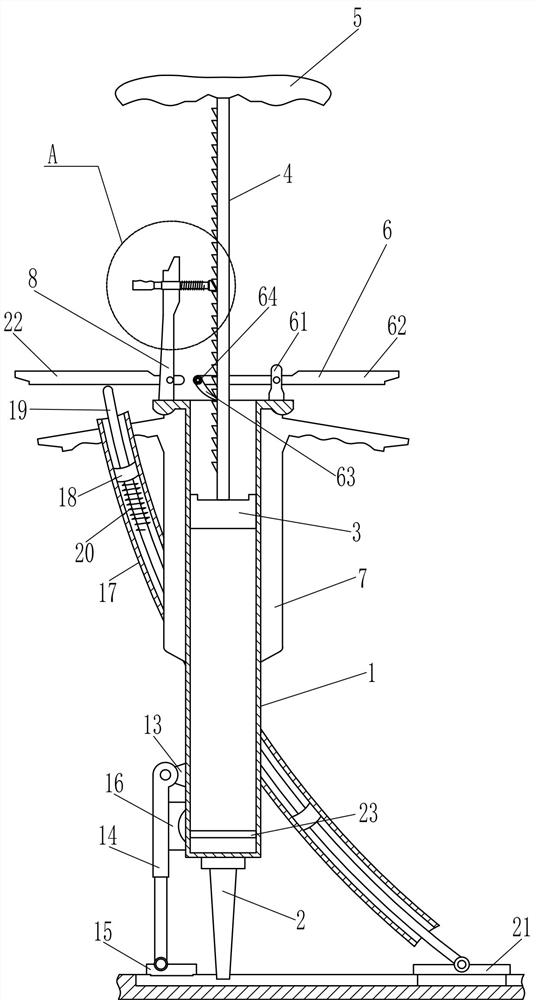

[0019] A kind of beautifying seaming equipment after tile laying, such as Figure 1-2 As shown, it includes pipe body 1, tapered pipe head 2, piston 3, ratchet rack 4, push plate 5, push device 6, installation sleeve 7, installation rod 8, guide sleeve 9, guide rod 10, wedge block 11 , the first compression spring 12, support seat 13, telescopic rod 14, pressing plate 15 and buffer pad 16, the bottom of the pipe body 1 is provided with a tapered pipe head 2, the inside of the pipe body 1 is slidably connected with a piston 3, and the top of the piston 3 is provided with There is a ratchet bar 4, the top of the ratchet bar 4 is provided with a push plate 5, the right side of the top of the pipe body 1 is provided with a pusher 6, the upper parts of the left and right sides of the pipe body 1 are provided with mounting sleeves 7, and the left side of the pipe body 1 top is provided with There is a mounting rod 8, the upper part of the mounting rod 8 is provided with a guide slee...

Embodiment 2

[0023] On the basis of Example 1, such as figure 1 As shown, it also includes arc-shaped plate 17, guide sleeve 18, arc-shaped rod 19, second compression spring 20, friction plate 21 and second grip bar 22, and the rear side of pipe body 1 is provided with arc-shaped plate 17, and the arc-shaped The upper and lower sides of the plate 17 are provided with guide sleeves 18, and the guide sleeve 18 is slidably connected with an arc rod 19. The second compression spring 20 is connected between the arc rod 19 and the upper guide sleeve 18, and the arc rod 19 The end is rotatably connected with a friction plate 21 , and the lower part of the mounting rod 8 is rotatably connected with a second handle 22 .

[0024] When the equipment performs beautiful seam work on the gap between tiles, swing the second lever 22 up and down. When the second lever 22 swings, it pushes the arc rod 19 to reciprocate up and down. The second compression spring 20 is repeatedly stretched and passes through...

Embodiment 3

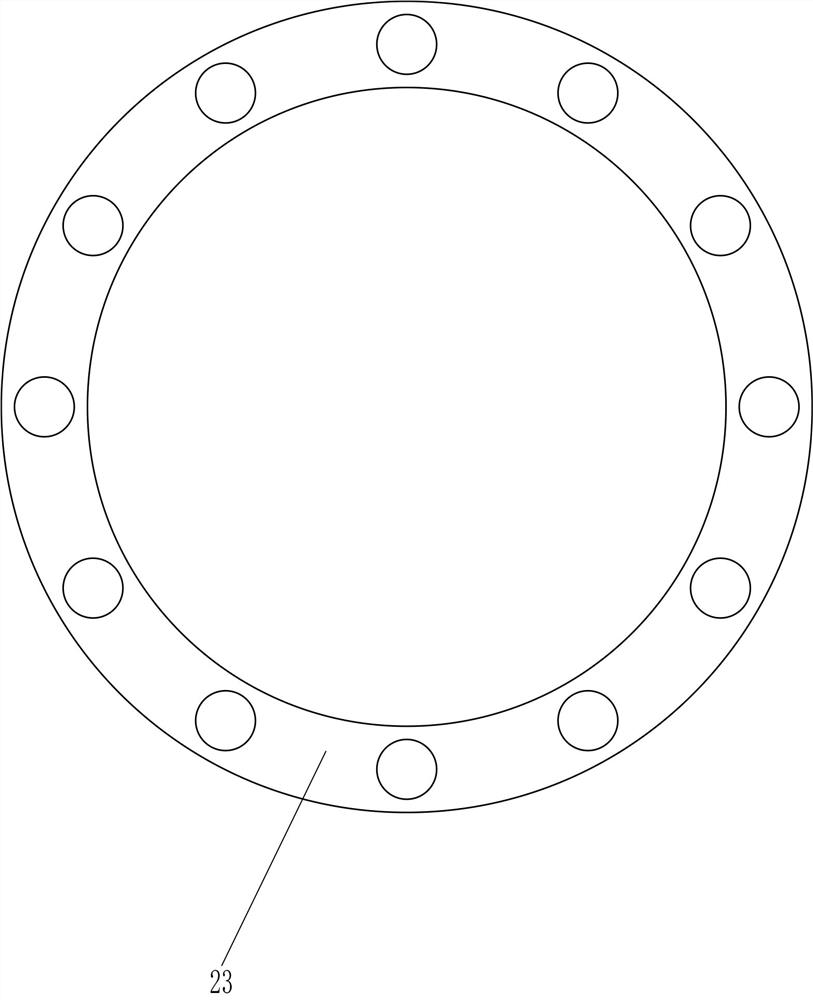

[0026] On the basis of Example 2, such as figure 1 and image 3 As shown, a separating ring 23 is also included, and the lower part of the pipe body 1 is provided with a separating ring 23 .

[0027] Through the partition ring 23, it acts as a reminder. When the piston 3 moves down to contact with the partition ring 23, it reminds the workers to add the beautifying agent in time. The beautifying agent discharged from the shaped pipe head 2 is hollowed out, which achieves the effect of ensuring a sufficient amount of beautifying agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com