Eccentric-wear-preventing packing for oil extraction

A technology of grinding and anti-biasing, which is applied in earth-moving drilling, drilling equipment, wellbore/well components, etc., can solve the problems of poor elastic compensation ability of packing, short service life of packing, and low utilization rate of base material, etc. To achieve the effect of reducing the difficulty of replacement, reducing one downtime and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

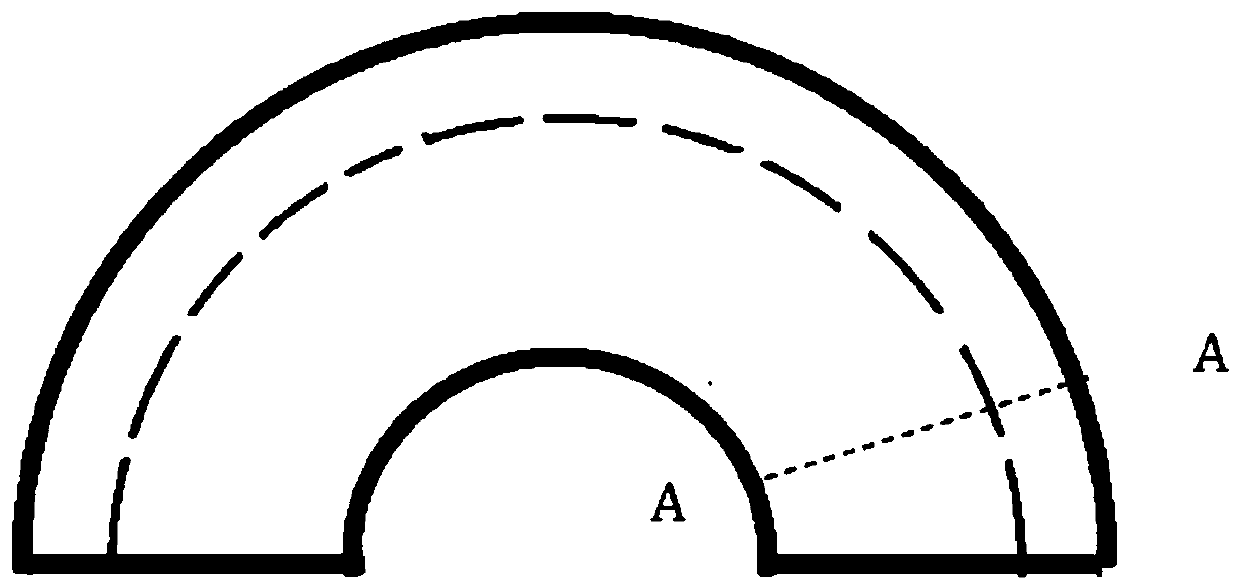

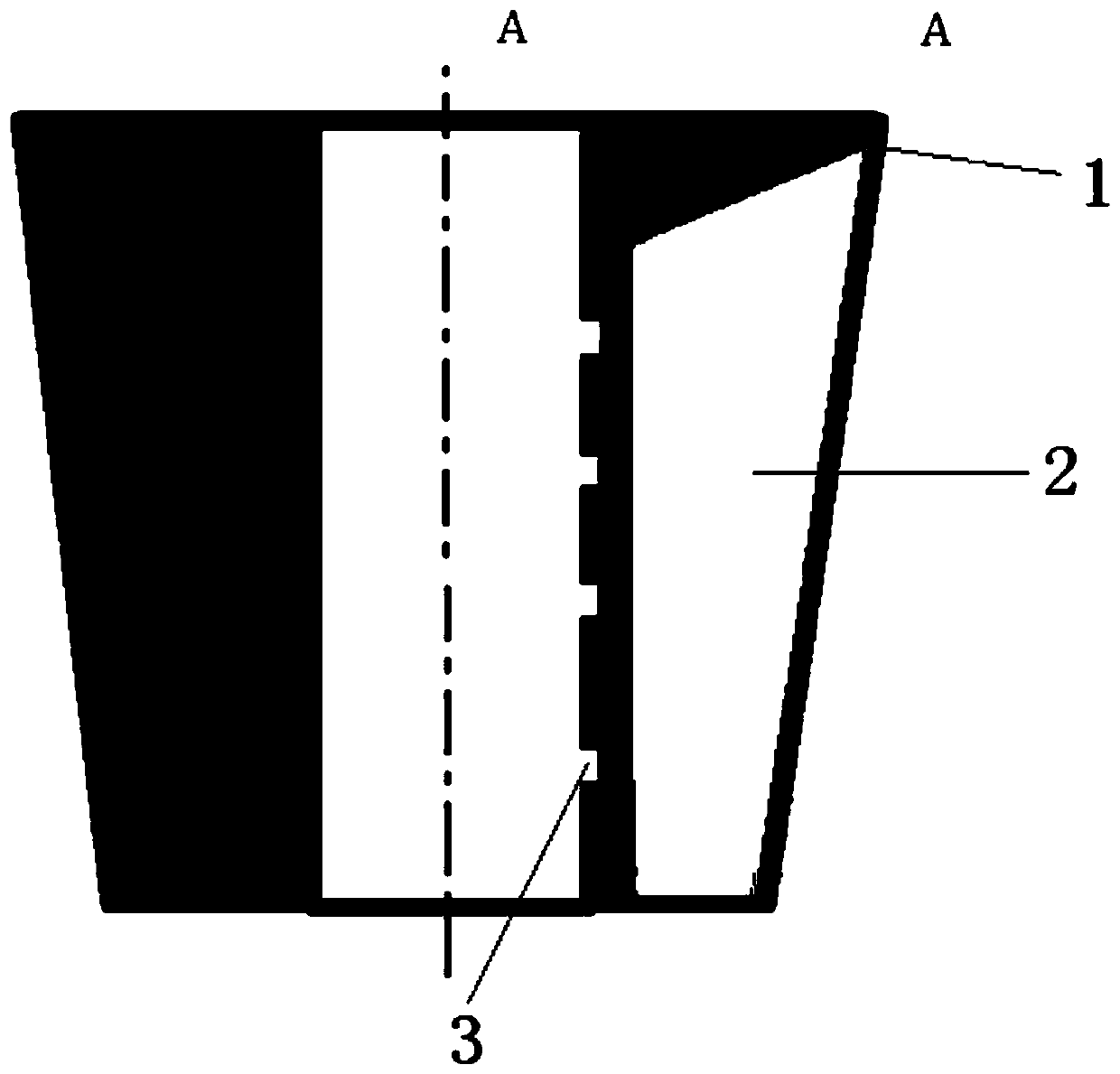

[0021] Such as figure 1 , figure 2 As shown, an anti-eccentric wear packing for oil production includes two semi-annular disc root bodies 1; a liquid chamber 2 is designed inside the disc root body 1, and the liquid chamber 2 is filled with a filling liquid.

[0022] The liquid chamber 2 is an annular space matching the shape of the disc root body 1 .

[0023] The thickness of the outer side of the top of the disc root body 1 from the liquid chamber 2 is smaller than the thickness of the inner side of the top of the disc root body 1 from the liquid chamber 2, which not only ensures the strength of the top of the packing, but also saves the use of raw materials. At the same time, when replacing the packing , easy to remove the old packing. The outer wall thickness of the disc body 1 on the outer side of the liquid chamber 2 is 2 mm, which ensures the overall strength of the packing and reduces the material consumption of the non-friction contact surface. The inner wall thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com