Construction method for water-rich sand layer shield to pass through steel tube soil nail area

A technology of water-rich sand layer and construction method, which is used in earth-moving drilling, infrastructure engineering, sheet pile wall, etc., can solve the problems of inability to excavate, wear of cutter head and cutter, and high construction cost, and achieve excellent long-term strength and durability. , The effect of reducing tool wear and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

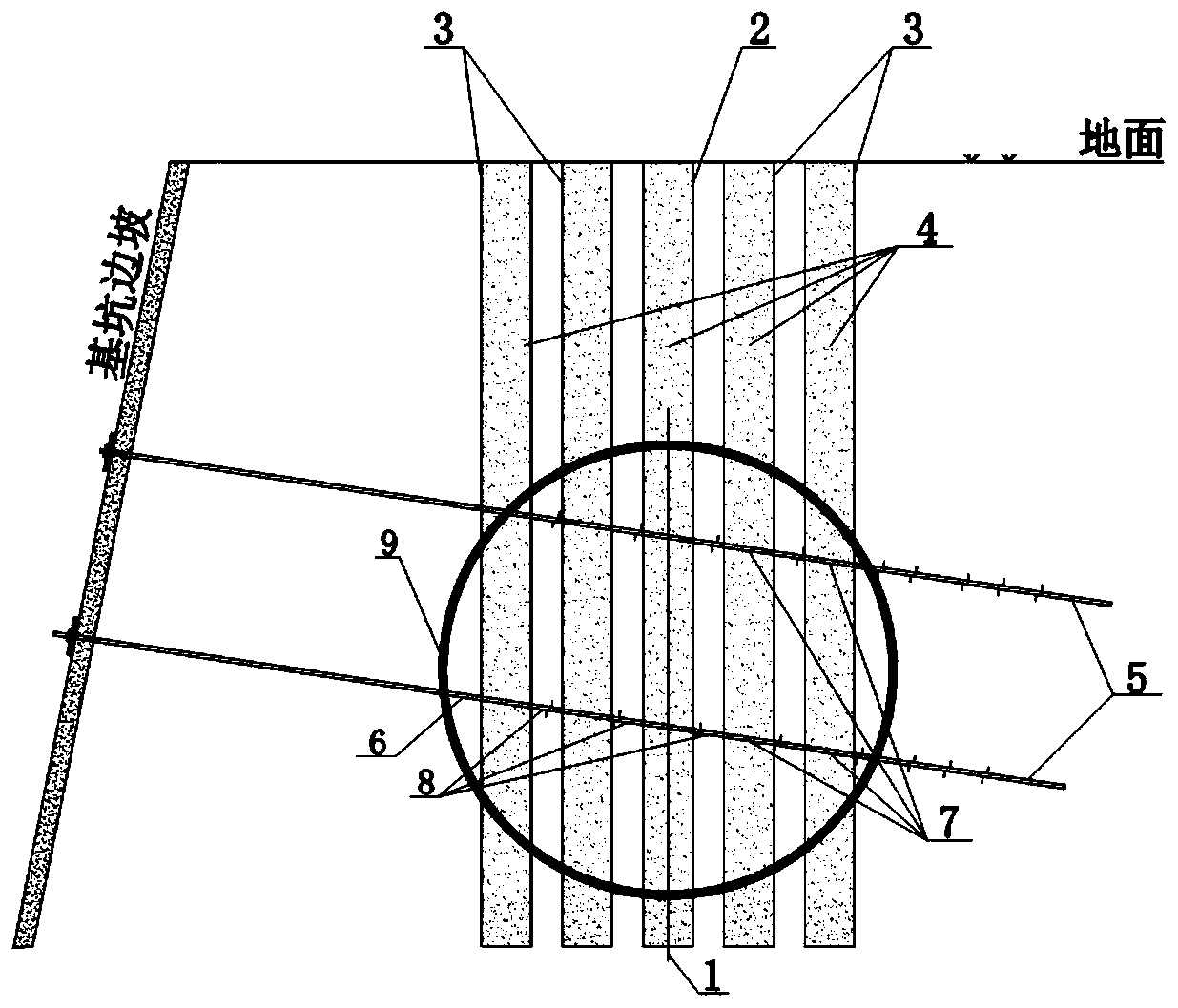

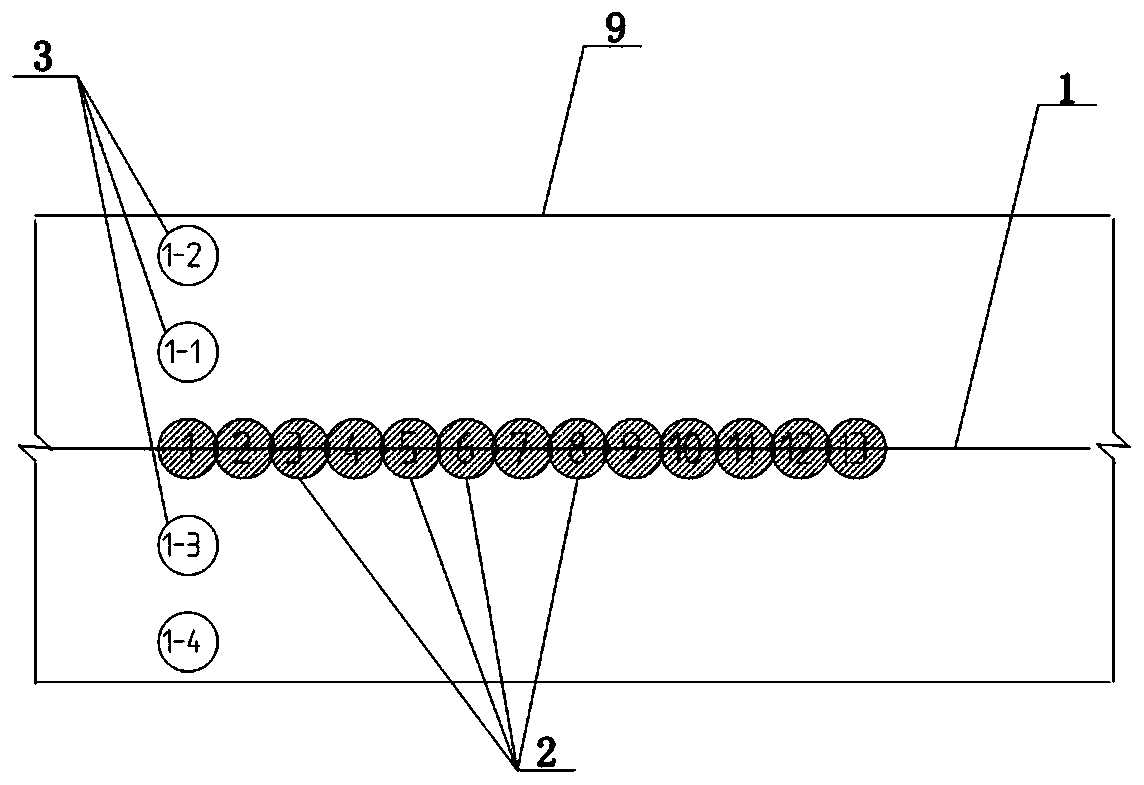

[0050] like figure 1 and figure 2 As shown, the method includes:

[0051] Step 1. Clean up the gravel and debris in the construction site, level the construction site, and compact and harden the construction site.

[0052] Step 2. Design the position of the longitudinal probe hole 2 along the tunnel centerline 1. The diameter of the longitudinal probe hole 2 is φ800mm, the hole distance is 750mm, and the occlusal width is 50mm. By analogy, the position of the horizontal clearance hole 3 is confirmed according to the position of the longitudinal probe hole 2. The diameter of the horizontal clearance hole 3 is φ800 mm, and the hole distance is 1300 mm. out), and add a sub-serial number on the basis of the number of the longitudinal probe hole 2 as the number of the horizontal clearance hole 3. 2#, 1-3#, 1-4#, and so on, are used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com