Structural system and construction method of integrated flat cavity pipeline for oil and gas multiphase transportation

A pipeline and oil and gas technology, which is applied in the structural system and construction field of oil and gas multiphase transportation integrated flat cavity pipeline, can solve the problems of poor stability and impermeability, small pipeline diameter, etc., to ensure stability, less deposition medium, and improve Effects on load carrying capacity and stability properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

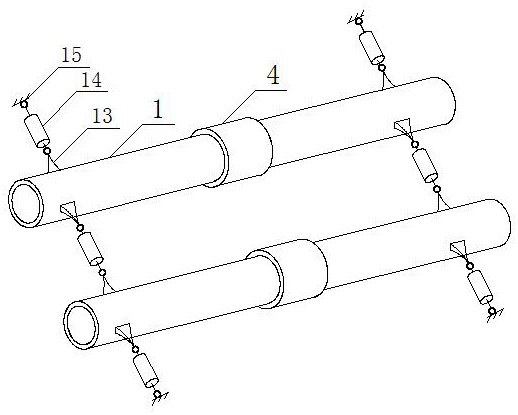

[0059] refer to figure 1 , this kind of oil and gas multi-phase transportation integrated flat cavity pipeline structure system is composed of two pipelines connected by GFRP anti-buckling energy-dissipating dampers, in which a single pipeline is composed of straight pipeline monomers connected by integral nodes, combined with Figure 4 , Figure 5 As shown, the straight pipe unit is formed by two seamless inner and outer layers of wound GFRP circular pipes and interlayer self-compacting fine stone concrete layers, as shown in Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, the outer side of the inner GFRP round pipe and the inner side of the outer GFRP round pipe are provided with shear connection keys according to certain rules, and the straight pipes are connected by integral nodes on site, as shown in Image 6 , Figure 7 As shown, the integral joint is formed by sandwiching concrete between the inner and outer two-layer GFRP circular pipes. The unconcrete i...

Embodiment 2

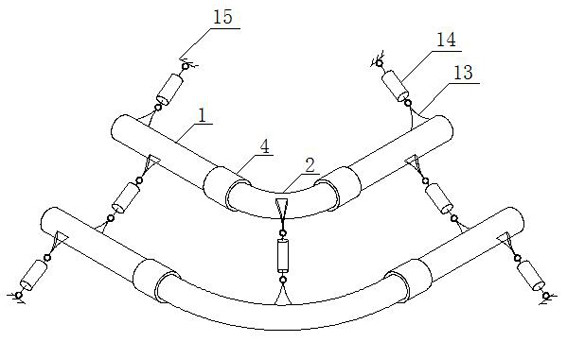

[0065] refer to figure 2 , this kind of oil and gas multiphase transportation integrated flat cavity pipeline structure system is composed of two pipelines connected by GFRP anti-buckling energy dissipation damper. The monomer is composed of integral node connections, combined with Figure 12 As shown, the curved pipe unit is formed by two seamless inner and outer layers of wound GFRP circular pipes and interlayer self-compacting fine stone concrete, as shown in Fig. Figure 9 , Figure 11 As shown, the outer side of the inner GFRP round pipe and the inner side of the outer GFRP round pipe are provided with shear connection keys according to certain rules, and the straight pipe unit and the curved pipe unit are connected on site with integral nodes, as shown in Image 6 , Figure 7 As shown, the integral joint is formed by sandwiching concrete between the inner and outer two-layer GFRP circular pipes. The unconcrete integral joint is connected and fixed with the two pipes ...

Embodiment 3

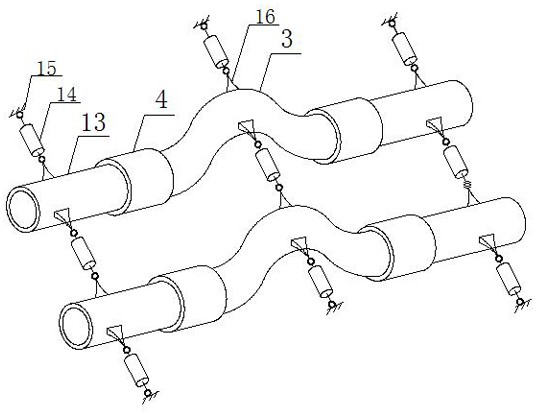

[0069] refer to image 3 , this kind of oil and gas multiphase transportation integrated flat cavity pipeline structure system is composed of two pipelines connected by GFRP anti-buckling energy dissipation dampers, in which a single pipeline is composed of straight pipeline monomers and spanning pipeline monomers connected by integral nodes , combined with Figure 13 As shown, the spanning pipe unit is formed by two seamless inner and outer layers of wound GFRP round pipes and interlayer self-compacting fine stone concrete, as shown in Figure 9 , Figure 11 As shown, the outer side of the inner GFRP round pipe and the inner side of the outer GFRP round pipe are provided with shear connection keys according to certain rules, and the integral node field connection is adopted between the straight pipe unit and the spanning pipe unit, as shown in Image 6 , Figure 7 As shown, the integral joint is formed by sandwiching concrete between two layers of GFRP circular pipes insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com