Electrode boiler closed type circulating water system with voltage stabilizing function

An electrode boiler, closed cycle technology, applied in thermal storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of increasing the workload of system operation and maintenance, system failure sources, and increasing system investment costs, etc. To achieve the effect of simple structure, stable operation and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

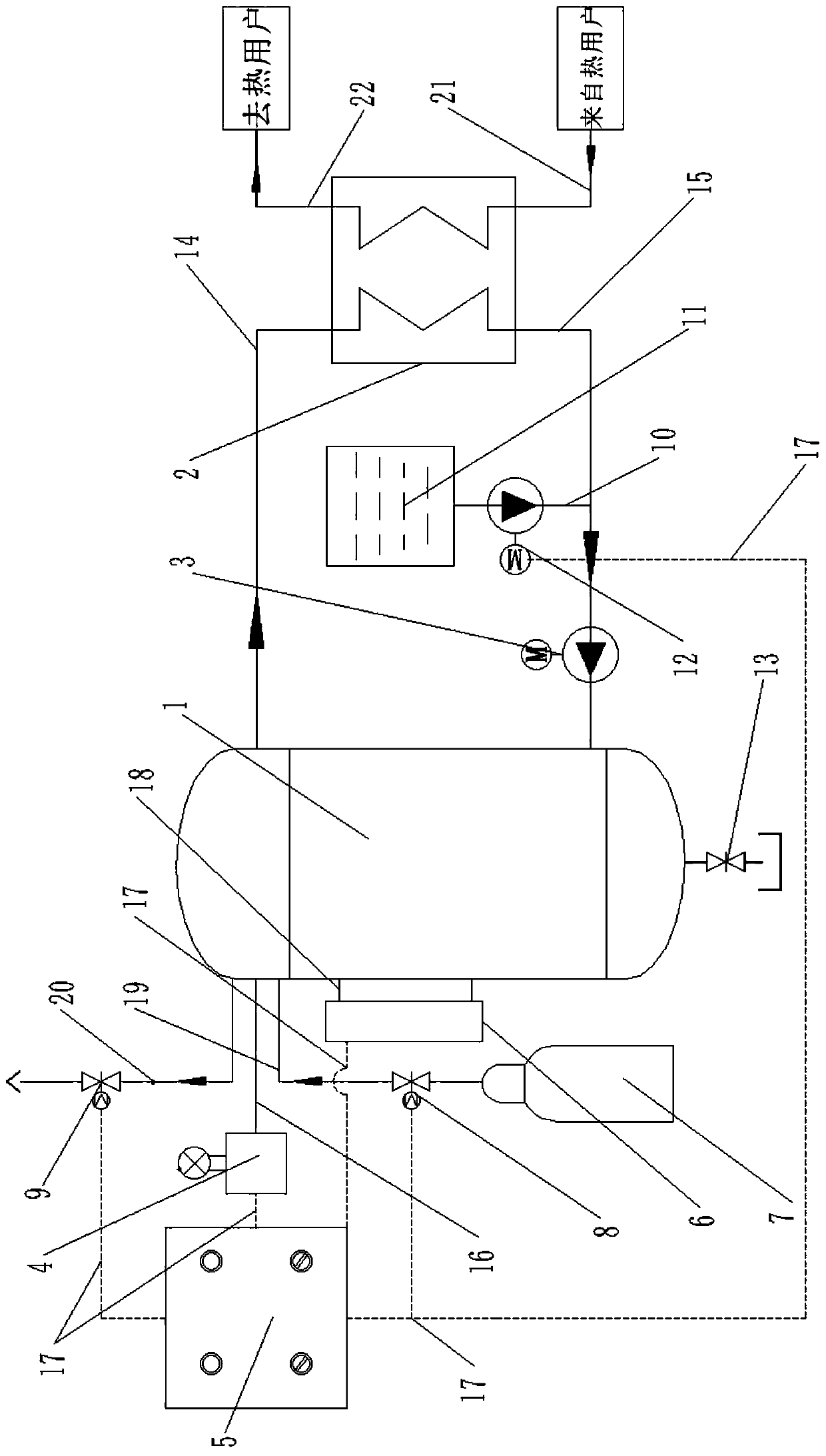

[0021] exist figure 1 Among them, the electrode boiler closed circulating water system with its own voltage stabilizing function in the present invention includes an electrode boiler 1, a plate heat exchanger connected to the electrode boiler through an upper circulating water pipe 14 and a lower circulating water pipe 15 installed on the side of the electrode boiler 2. The circulating pump 3 installed on the lower circulating water pipeline, the pressure transmitter 4 connected to the upper side of the electrode boiler through the gas pipeline 16, the control system 5 connected to the pressure transmitter through the circuit cable 17, and the circuit The cable is connected to the control system and the liquid level gauge 6 connected to the side of the electrode boiler through the hydraulic pipeline 18, and the gas storage tank 7 connected to the upper side of the electrode boiler through the intake pipeline 19 is installed on the intake pipeline and passed through the circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com