Distributed assembly type permutation flow shop scheduling optimization method and system

An optimization method and distributed technology, applied in control/regulation systems, general control systems, instruments, etc., can solve the problems of difficult implementation, large amount of calculation, low flexibility, etc., and achieve the goal of shortening the completion time and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

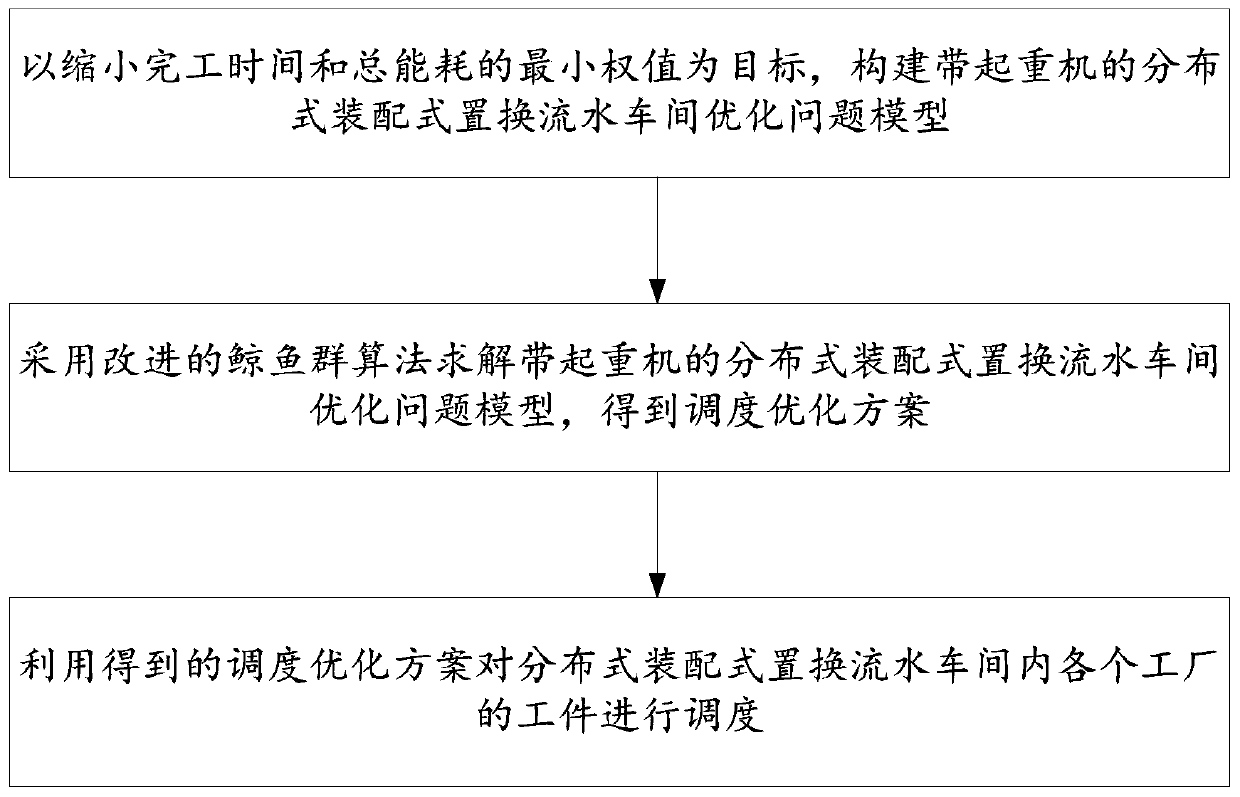

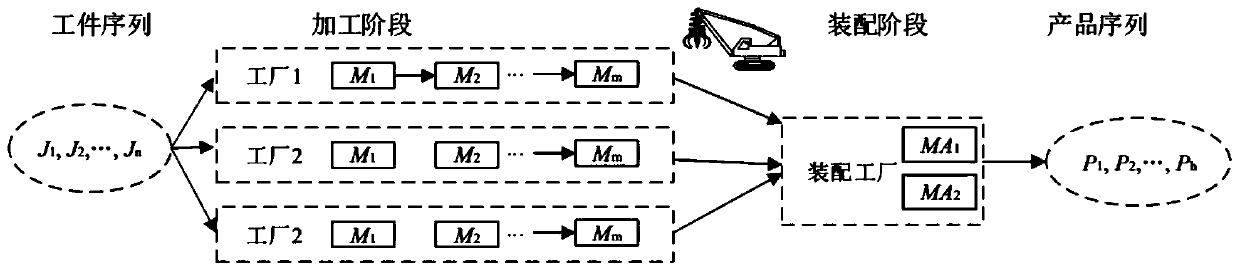

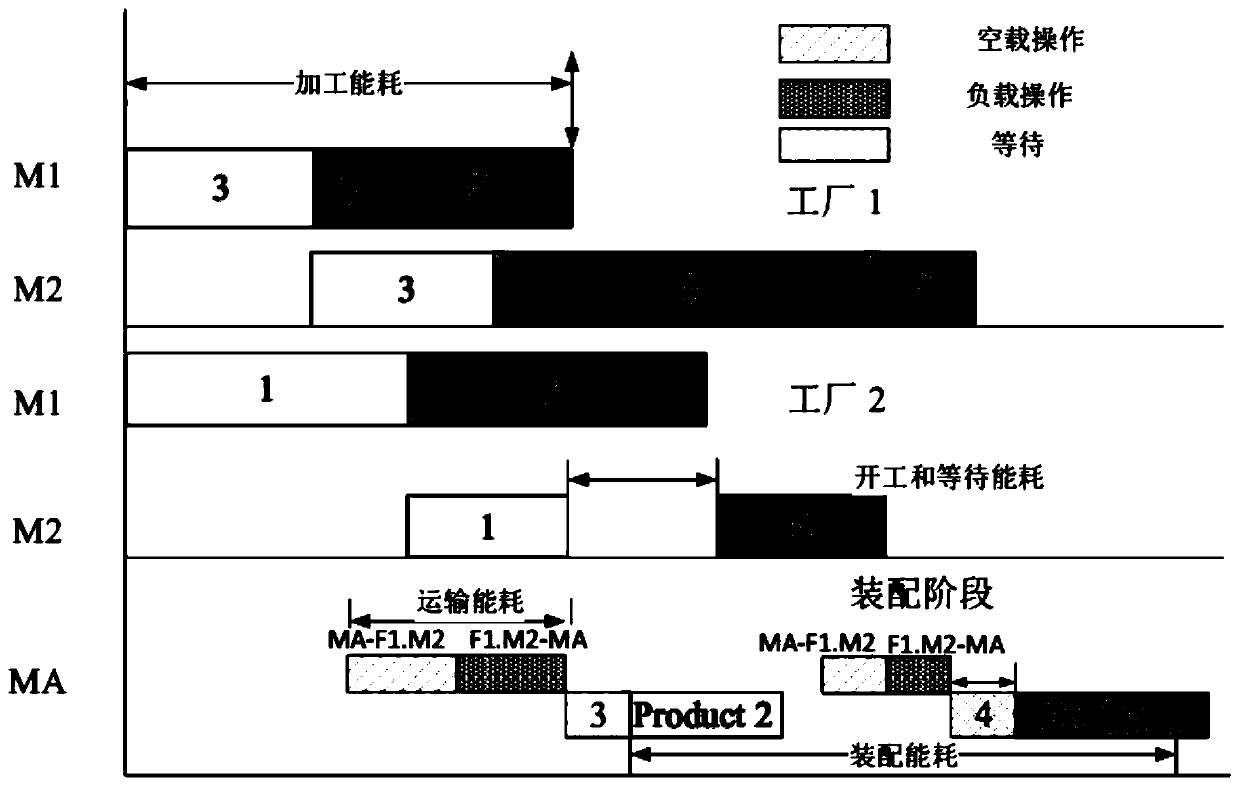

[0051] figure 1 It is a flow chart of the crane-based distributed assembly replacement flow workshop optimization method involved in this embodiment. This example takes the crane as the research object, and transports the workpiece completed on the processing machine tool to the assembly machine for product assembly; this example also considers two types of objectives, including completion time and during the processing stage, the crane transportation process and the assembly process total energy consumption in . In this embodiment, the improved Whale Optimization Algorithm (IWOA) is used to solve the crane transportation problem (DAFSP-CT) of the distributed assembly replacement flow shop considering the minimum weighted value of completion time and energy consumption.

[0052] Such as figure 1 As shown, the optimization method for the distributed assembled replacement flow shop based on crane transportation includes the following steps:

[0053] S101, according to the cha...

Embodiment 2

[0175] This embodiment provides a crane-based distributed assembly replacement flow workshop optimization system, the system includes:

[0176] The model building module is used to construct the optimization problem model of the distributed assembled replacement flow shop with cranes with the goal of reducing the minimum weight of completion time and total energy consumption;

[0177] The model solving module is used to use the improved whale swarm algorithm to solve the optimization problem model of the distributed assembled replacement flow shop with cranes, and obtain the scheduling optimization scheme;

[0178] The optimization scheduling module is used to schedule the workpieces of each factory in the distributed assembly type replacement flow workshop by using the obtained scheduling optimization scheme.

Embodiment 3

[0180] This embodiment provides a computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the following steps are implemented:

[0181] Aiming at reducing the minimum weight of completion time and total energy consumption, an optimization problem model of a distributed assembly-type replacement workshop with cranes is constructed;

[0182] The improved whale swarm algorithm is used to solve the optimization problem model of the distributed assembled replacement flow workshop with cranes, and the scheduling optimization scheme is obtained;

[0183] The scheduling optimization scheme obtained is used to schedule the workpieces of each factory in the distributed assembly replacement flow workshop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com