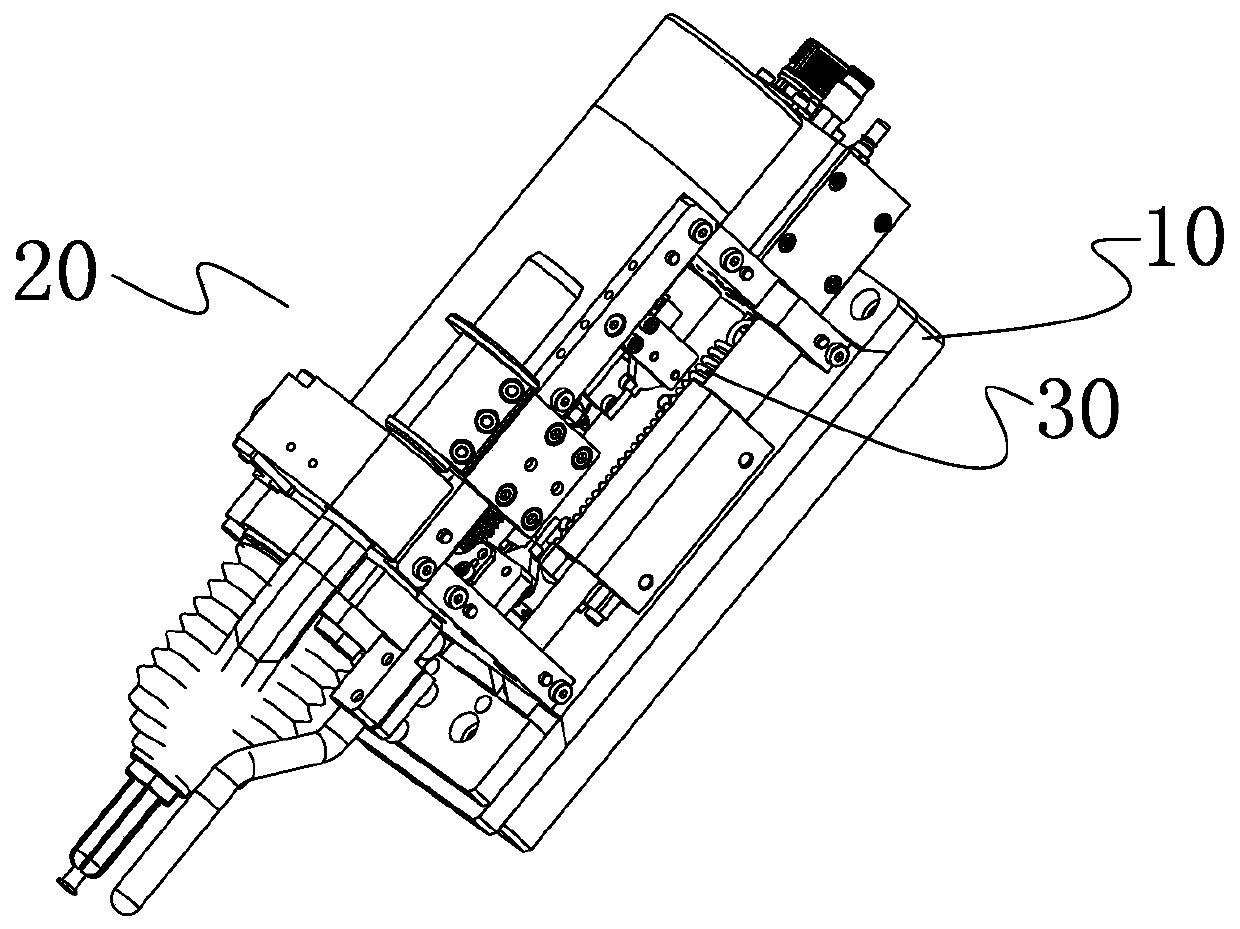

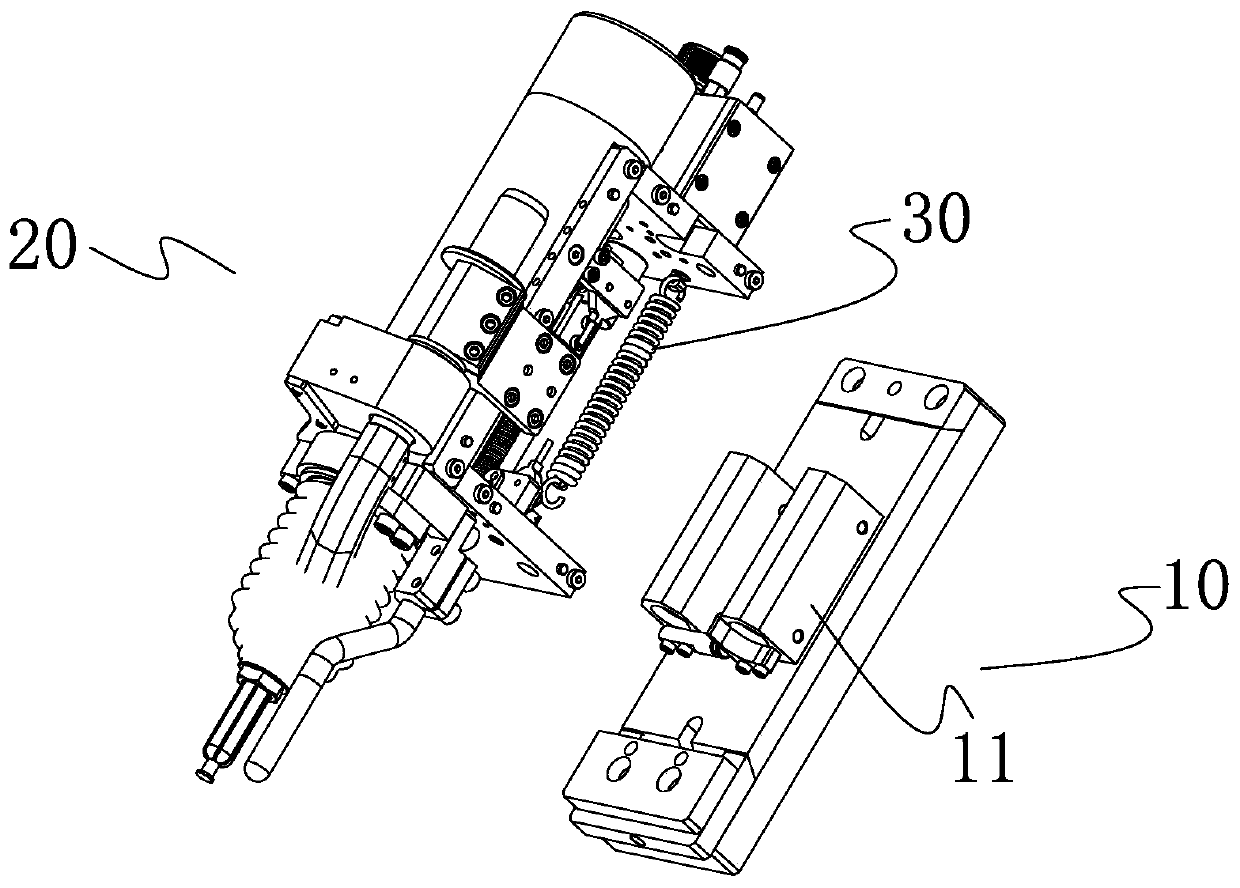

Intelligent workpiece height self-adaption device of stud welding device

A welding device and self-adaptive technology, applied in welding accessories, welding equipment, electrode support devices, etc., can solve the problems of precise control of stud penetration, inability to automatically adapt to the height of the workpiece, and difficulty in adapting to the height of stud welding equipment. Precise control of penetration depth, easy penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

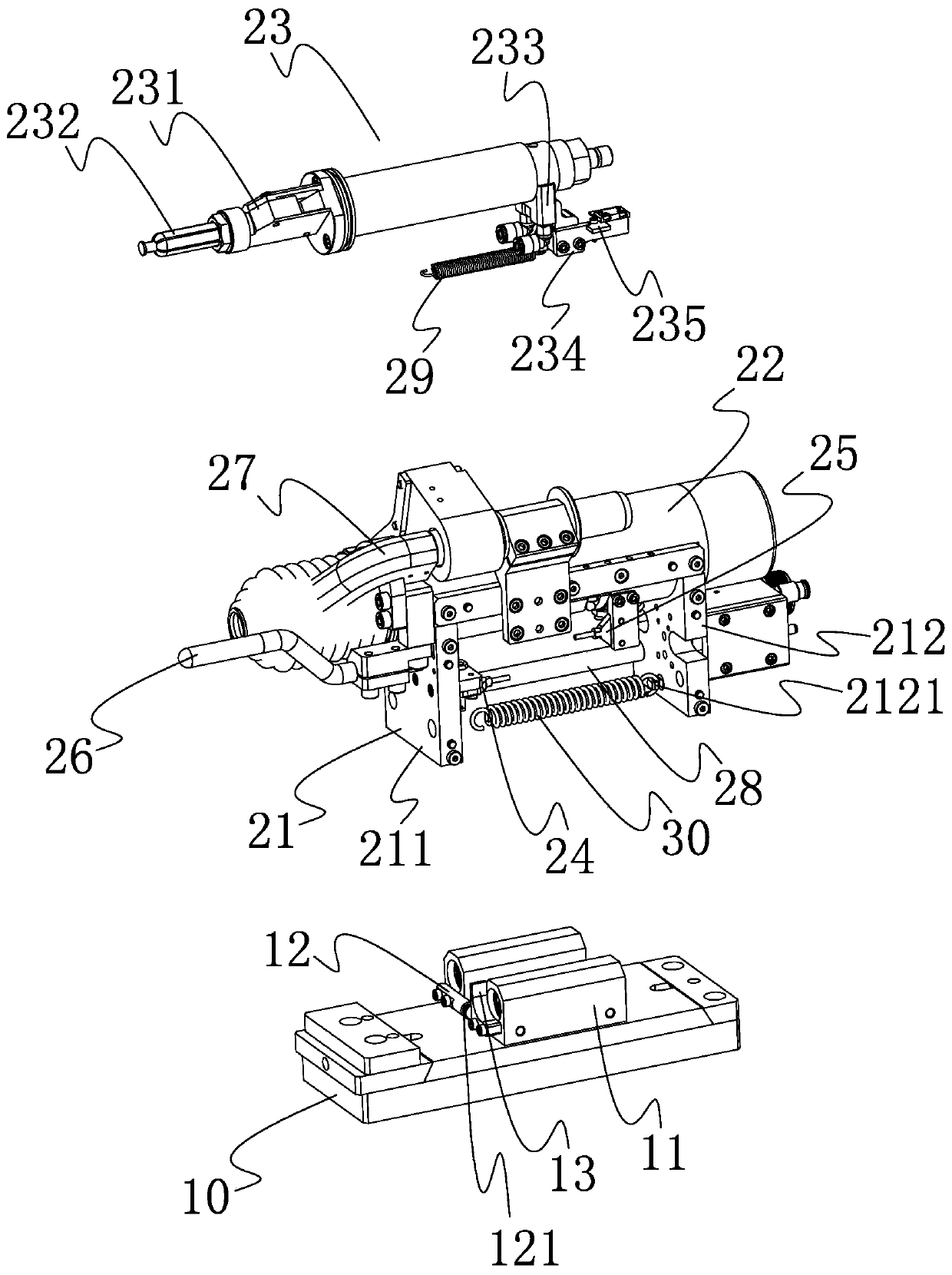

[0040] In other implementations, the second position sensor 252 and the second grating 2352 can also be eliminated. The first position sensor 251 senses the first grating 2351 based on the reference origin to detect the second moving distance.

[0041] Before welding, if the height of the workpiece is relatively high, the distance that the workpiece height intelligent adaptive device of the stud welding device moves downward exceeds the first distance between the chuck 232 and the second end of the abutment column 26, firstly The gun core 23 moves upward relative to the gun barrel 22 for a first moving distance under the abutting action of the workpiece, and then the workpiece abuts against the abutting column 26, which drives the welding torch body 20 to move upward for a third moving distance relative to the base 10 as a whole. During welding, the main body 20 of the welding torch moves upward as a whole, and the gun core 23 does not move relative to the gun barrel 22. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com