Solder piece for segmental thermoelectric device connection and preparation method thereof

A thermoelectric device and solder tab technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device components, thermoelectric devices using only Peltier or Seebeck effects, etc., to simplify connection procedures and avoid adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

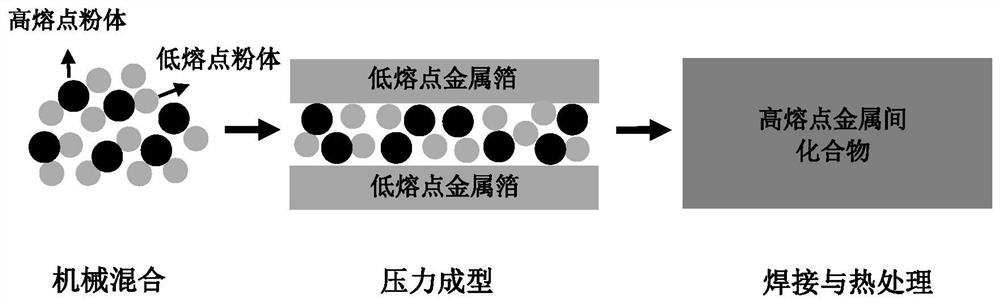

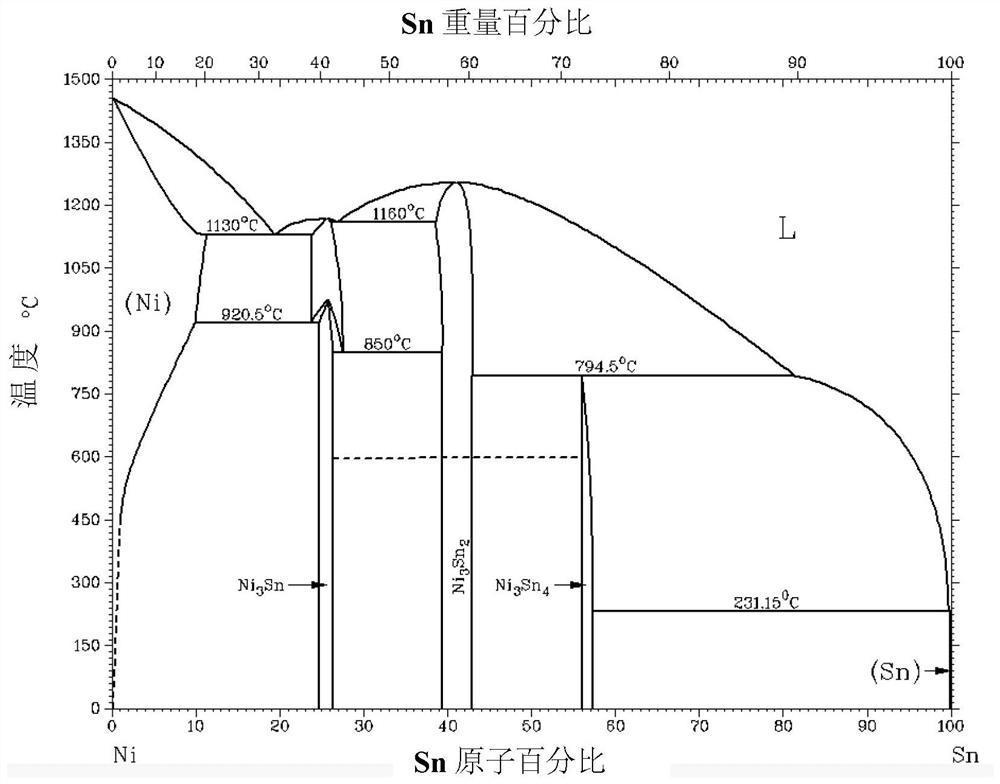

[0056] For the semi-Hausler (use temperature ~800°C) / skutterudite (~550°C) / bismuth telluride (~250°C) three-stage thermoelectric device, the low melting point metal tin (Sn) and the high melting point nickel ( Ni), tin foil thickness 50μm, tin powder particle size ~ 20μm, nickel powder particle size ~ 30μm, according to the Ni-Sn binary phase diagram ( figure 2 , the mass percentage of Sn is 40.3wt%) to generate Ni 3 Configure the tin powder and nickel powder according to the ratio of Sn, place it in a mixer, and mechanically mix it for 10 hours at a speed of 180r / min to obtain a uniform mixed powder;

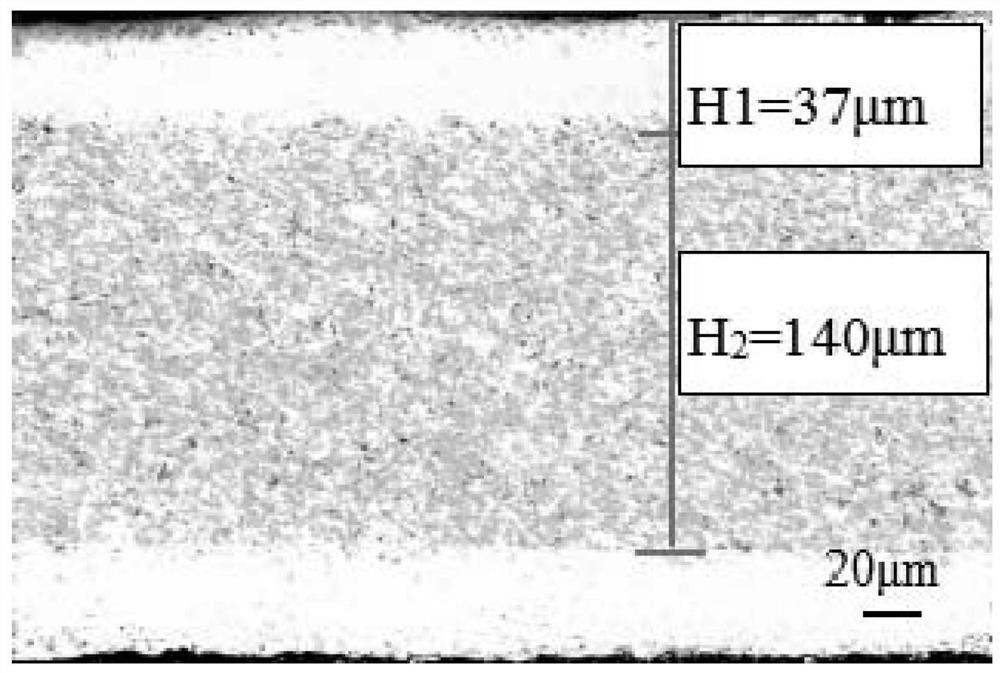

[0057] Weigh an appropriate amount of the nickel-tin mixed powder, spread evenly on the tin foil (control the addition 0.17g / cm 2 ), and covered with tin foil, placed in a mold with an inner diameter of 30 mm and a press, and applied a pressure of 20 MPa for 5 minutes to form the solder sheet, as image 3 As shown, the thickness of B in the solder piece is 140μm;

[0058] D...

Embodiment 2

[0060] For silicon germanium (use temperature ~ 1000°C) / skutterudite (~550°C) / bismuth telluride (~250°C) three-stage thermoelectric devices, use low melting point metal tin (Sn) and high melting point nickel (Ni) , the thickness of tin foil is 50 μm, the particle size of tin powder is ~20 μm, and the particle size of nickel powder is ~30 μm, according to the Ni-Sn binary phase diagram ( image 3 , the mass percent of Sn is 59.73wt%) to generate Ni 3 sn 2 Configure the tin powder and nickel powder according to the ratio, place it in a mixer, and mechanically mix it for 10 hours at a speed of 180r / min to obtain a uniform mixed powder;

[0061] Weigh an appropriate amount of the nickel-tin mixed powder, spread evenly on tin foil (control addition 0.14g / cm 2 ), and covered with tin foil, placed in a mold with an inner diameter of 30 mm and a press, and applied a pressure of 20 MPa for 5 minutes to form the solder sheet, and the thickness of B in the solder sheet is 130 μm;

[0...

Embodiment 3

[0064] The tetrahedrite thermoelectric material contains sulfur, and the conventional brazing is used to connect the electrodes. The sulfur is easily lost, resulting in a significant decline in the thermoelectric performance of the material, and the preparation of the tetrahedrite thermoelectric device is very difficult. For tetrahedrite (~400°C) / bismuth telluride (~250°C) two-stage thermoelectric devices, low melting point metal tin (Sn) and high melting point tellurium (Te) are selected, the thickness of tin foil is 50 μm, and the particle size of tin powder is ~ 10μm, nickel powder particle size ~ 10μm, according to Te-Sn binary phase diagram ( Figure 5 , the mass percentage of Sn is 48.2wt%) to generate the ratio of SnTe to configure the tin powder and tellurium powder, and place it in a mixer, mechanically mix 20h at a rate of 250r / min to obtain a uniform mixed powder;

[0065] Weigh an appropriate amount of the mixed tellurium-tin powder, spread evenly on the tin foil (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com