Optical instrument for lens grinding

An optical instrument and lens technology, applied in the field of glasses, can solve the problems of low grinding efficiency, damage to the lens surface, and poor grinding accuracy, and achieve the effects of high grinding efficiency, guaranteed clarity, and guaranteed grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

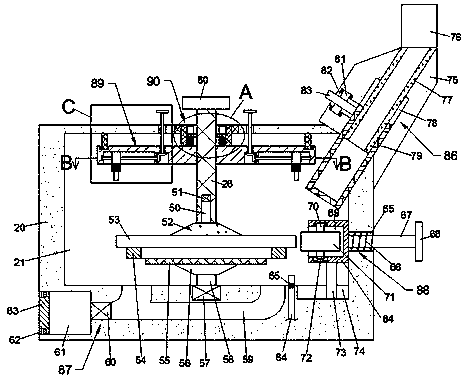

[0019] Combine below Figure 1-Figure 4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent.

[0020] The present invention relates to an optical instrument used for lens grinding, mainly used for lens grinding work, the present invention will be further described below in conjunction with the accompanying drawings of the present invention:

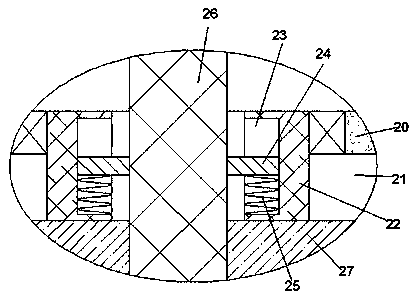

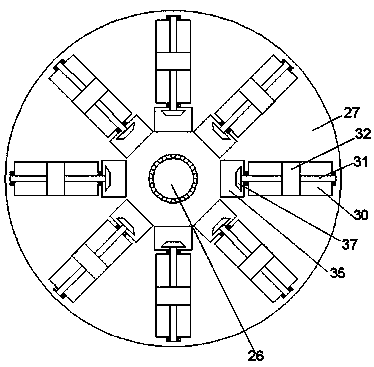

[0021] An optical instrument for lens grinding according to the present invention includes a body 20, a grinding cavity 21 is arranged in the body 20, a placing disc 55 is arranged in rotation in the grinding cavity 21, and the placing disc 55 is placed There is a picture frame 54, on which a lens 53 is placed, the upper side of the lens 53 is provided with a liftable stretching rod 26 through a telescopic device 90, the outer perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com