Rail vehicle roof drainage protection structure and drainage box

A technology for rail vehicles and protective structures, applied in the field of rail vehicles, can solve the problems of inconvenient removal, easy corrosion of threaded fasteners 300, cumbersome operation, etc., and achieves the effect of simple structure and avoiding poor drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

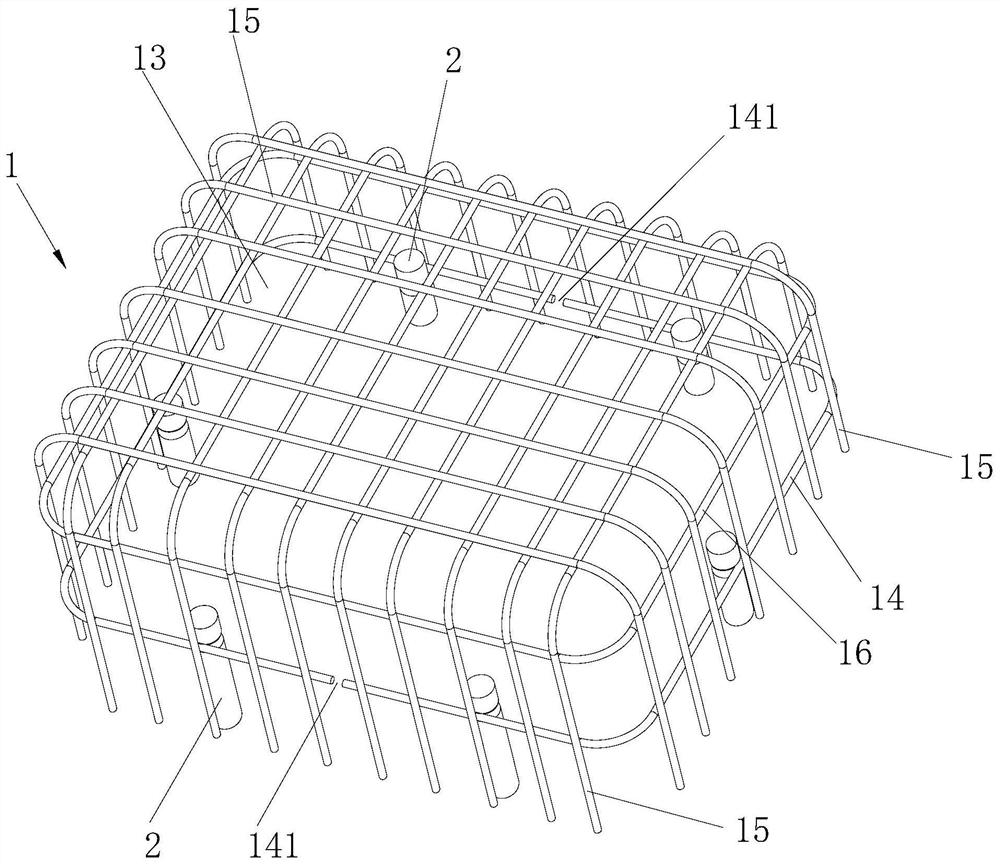

[0026] image 3 An embodiment of the rail vehicle roof drainage protection structure of the present invention is shown. The rail vehicle roof drainage protection structure of this embodiment includes a protective cover 1 and several mounting parts 2. The protective cover 1 includes a (Specifically the drainage box body 4) above the protective part 11 and the connecting part 12 located at the edge of the protective part 11, the protective part 11 is provided with a water leakage hole 13, the mounting part 2 is installed on the roof 3, and the connecting part 12 is downward Extend and connect with mounting part 2.

[0027] In the roof drainage protection structure of the present embodiment, the connecting portion 12 extends downwards and is connected with the mounting part 2 provided on the roof 3 to realize the installation of the protective cover 1, and the protective portion 11 with the water leakage hole 13 can prevent impurities such as leaves from When there are sundries ...

Embodiment 2

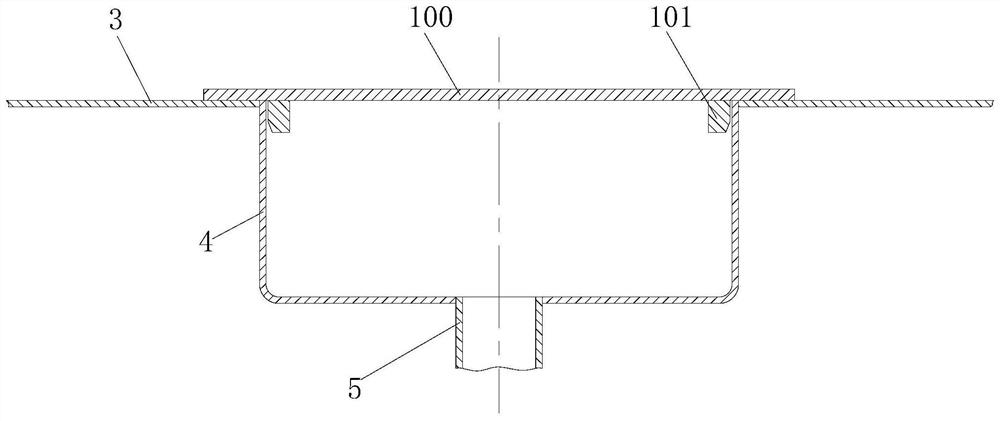

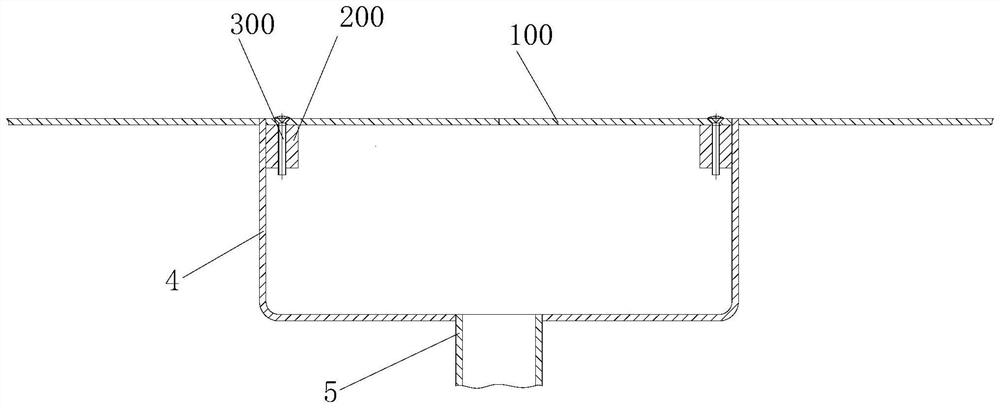

[0037] Figure 4 to Figure 5 An embodiment of the rail vehicle roof drainage box of the present invention is shown. The rail vehicle roof drainage box of this embodiment includes a drainage box body 4 and a drain pipe 5 arranged below the drainage box body 4, and also includes the above-mentioned In the rail vehicle roof drainage protection structure, the protection part 11 is located above the drainage box body 4 , and the connecting part 12 is located outside the drainage box body 4 .

[0038] The rail vehicle roof drainage box includes the above-mentioned drainage protection structure, so it also has the advantages of the above-mentioned drainage protection structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com