Novel cross-sectional structure of ore carrier

A cross-section, ore carrier technology, applied in the field of ships, can solve the problem that the tank capacity cannot meet the needs of low-density bauxite transportation, etc., to achieve the effect of ensuring operating economy, large cargo capacity, and reducing loading hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

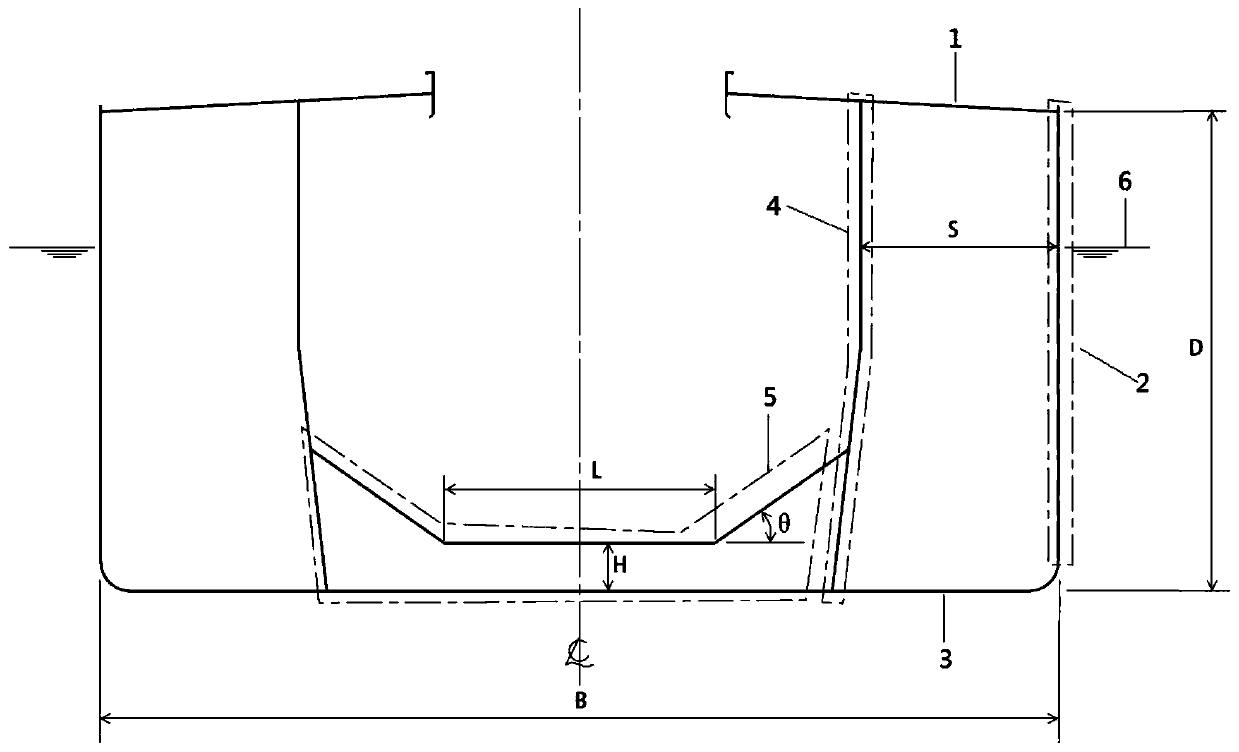

[0018] see figure 1 , a new cross-sectional structure of an ore ship, including an upper deck 1, an outer plate 2 and an outer bottom plate 3, a longitudinal bulkhead 4 of a cargo hold and a double bottom 5 of the cargo hold are arranged between the upper deck 1 and the outer bottom plate 3, and the double bottom of the cargo hold 5 The horizontal bottom is to be set amidships, and the upward sloping bottom is to be set close to the longitudinal bulkhead of the cargo hold. The minimum height H of the horizontal bottom is in the range of 0.1D meters to 0.15D meters, where D is the maximum height of the ship amidships. Type deep.

[0019] In this embodiment, the slope angle θ between the inclined bottom and the horizontal bottom surface is 35°-47°.

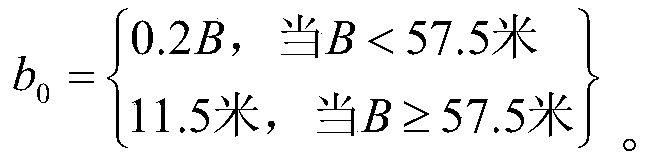

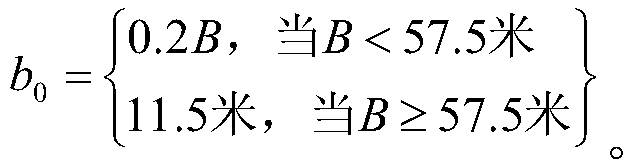

[0020] In this embodiment, the span L of the lowest part of the double bottom 5 of the cargo hold along the ship's width direction is 0.28B meters to 0.65B meters, where B is the maximum molded width of the ship at the midship.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com