A Bypass Control System Applicable to Expansion Units of Caes System

A bypass control, expander technology, applied in mechanical equipment, steam engine installations, machines/engines, etc., can solve the problems of low-pressure stage efficiency drop, unfavorable equipment safety, unfavorable equipment life, etc. The effect of reducing startup time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be noted that the following description is only a preferred embodiment of the present invention (only two bypasses are used), and does not limit the protection scope of the present invention.

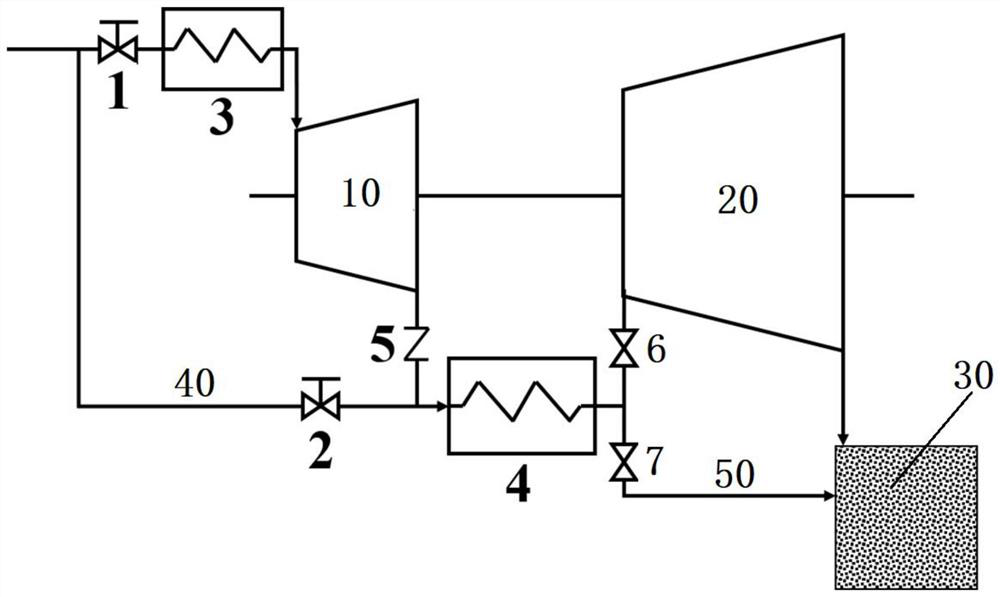

[0028] like figure 1 As shown, the bypass control system applicable to the expansion unit of the CAES system of the present invention is used to regulate and control the start-up and operation of the expansion unit in the CAES system. The expansion unit at least includes a high-pressure stage expander 10 and a low-pressure stage expander 20. The intake port of the high-pressure stage expander 10 communicates with a high-pressure gas source (not shown in the figure) through a main intake line, and the exhaust port communicates with the intake port of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com