Deep-graded surface water cooling partially-premixed gas furnace

A gas furnace, water cooling technology, applied in burners, combustion methods, combustion types, etc., can solve problems such as gaps, and achieve the effect of reducing oxygen partial pressure, ensuring economy, and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

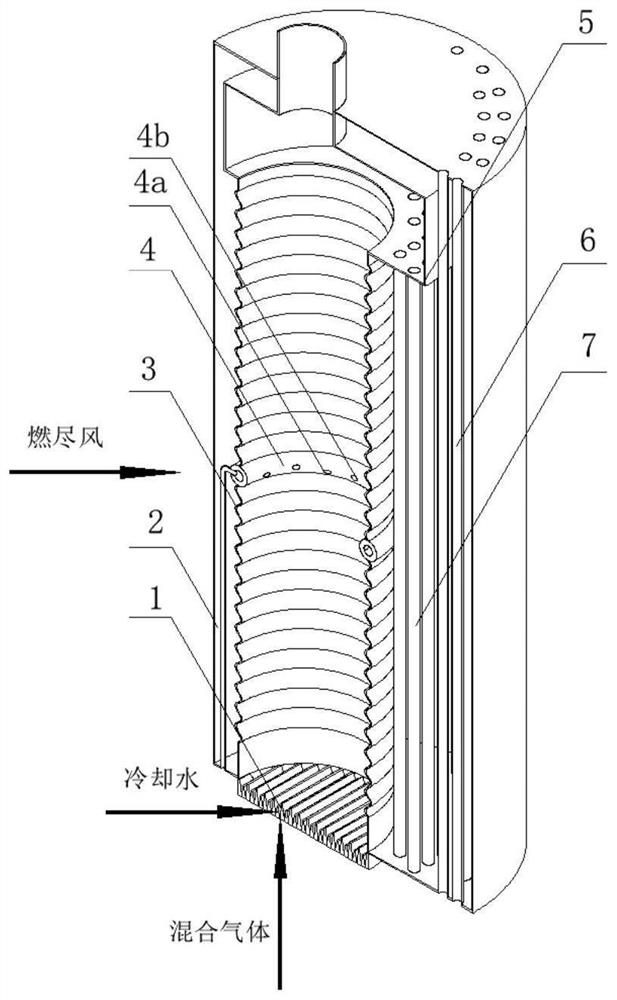

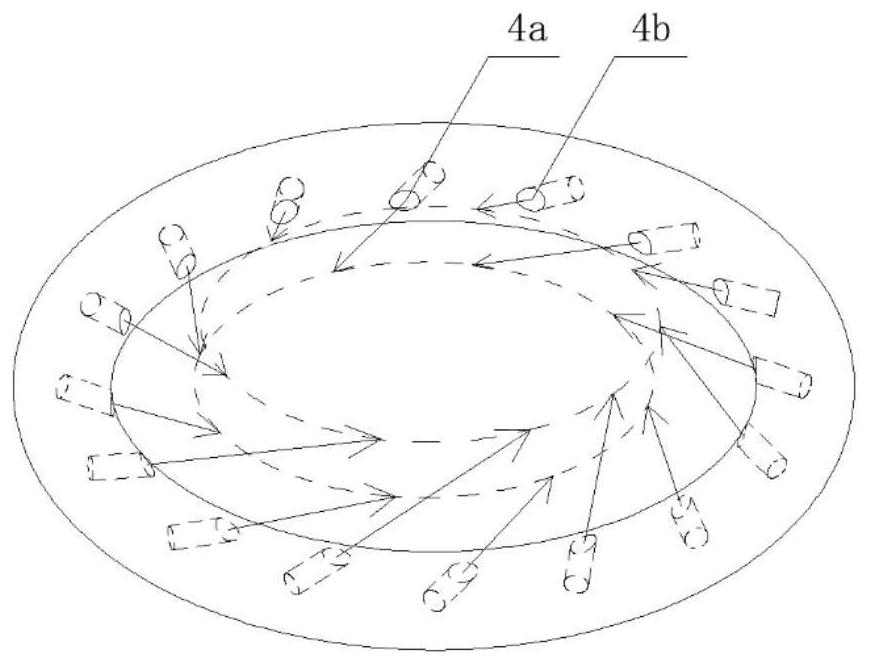

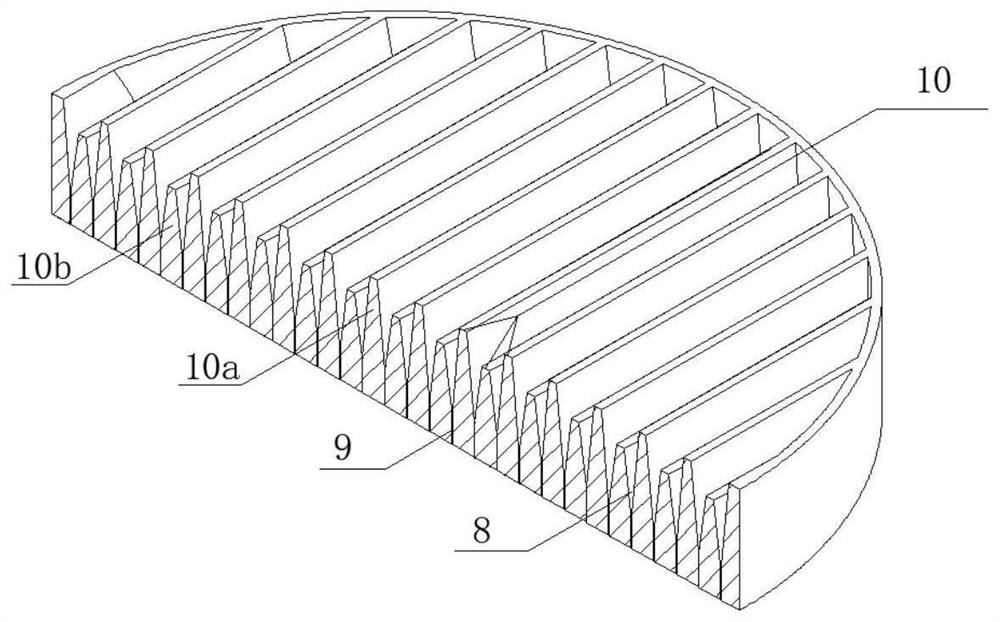

[0021] Such as Figure 1-Figure 3 Shown: In the present invention, the depth of the furnace air is graded, coupled with the surface water-cooled part of the premixed combustion, so that the gas fuel forms oxygen-poor low-temperature surface combustion in the gas device and oxygen-enriched supplementary combustion step by step, which effectively reduces the nitrogen oxidation generated during the combustion of the gas fuel. At the same time, ensure the complete combustion of gas fuel and ensure the economical operation of the boiler. Its main structure is that the mixed gas inlet is provided with an anti-tempering intake microchannel 9, and the cross-sectional size of the gradually expanding gas channel 8 gradually increases along the direction of flame propagation, and the high and low cooling components 10a and 10b on both sides are arranged alternately to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com