Rotating packed bed for treating ammonia-nitrogen wastewater

A technology of rotating packed bed and ammonia nitrogen wastewater, applied in the field of rotating packed bed, can solve the problems of difficulty in process realization and complex structure of gas distributor, and achieve the effect of reducing thickness and improving ammonia production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

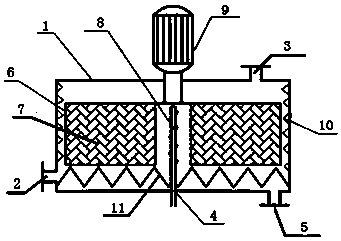

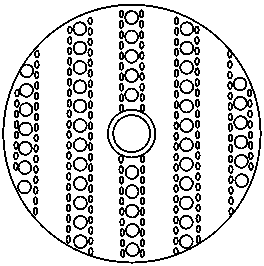

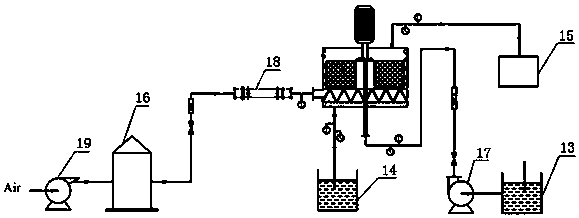

[0031] A rotary packed bed for treating ammonia nitrogen wastewater, comprising a shell 1, a gas inlet 2 is provided on one side of the shell 1, a gas outlet 3 is provided on the top, a liquid inlet 4 and a liquid outlet 5 are respectively provided on the bottom, and the shell 1 is provided with a ring-shaped packing support frame 6, and the packing support frame 6 is provided with a filler 7, and the center of the packing support frame 6 is provided with a tube-type liquid distributor 8, and the connecting pipe of the tube-type liquid distributor 8 is provided with a number of nozzles , the top center of the packing support frame 6 is connected to the driving device 9 through the rotating shaft, the gas inlet 2 is provided with a corrugated gas separator plate 11, and the side walls of the housing 1 parallel to the rotating shaft are respectively provided with a number of liquid redistributors 10.

[0032] The gas inlet 2 of the rotary packed bed of the present invention is co...

Embodiment 2

[0035] A rotary packed bed for treating ammonia nitrogen wastewater, comprising a shell 1, a gas inlet 2 is provided on one side of the shell 1, a gas outlet 3 is provided on the top, a liquid inlet 4 and a liquid outlet 5 are respectively provided on the bottom, and the shell 1 is provided with a ring-shaped packing support frame 6, and the packing support frame 6 is provided with a filler 7, and the center of the packing support frame 6 is provided with a tube-type liquid distributor 8, and the connecting pipe of the tube-type liquid distributor 8 is provided with a number of nozzles , the top center of the packing support frame 6 is connected with the driving device 9 through the rotating shaft, the gas inlet 2 is provided with a bronchial gas distributor 12, and the side walls of the housing 1 parallel to the rotating shaft are respectively provided with a number of liquid redistributors 10 .

[0036] The gas inlet 2 of the rotary packed bed of the present invention is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com