Catalyst for catalyzing isocyanic acid produced in urea pyrolysis process to hydrolyze so as to generate ammonia and preparation method thereof

A catalyst and isocyanic acid technology, applied in the direction of physical/chemical process catalysts, ammonia preparation/separation, molecular sieve catalysts, etc., can solve the problems of catalysts with small specific surface area, high temperature deactivation, unfavorable, etc., to achieve favorable catalytic reactions, Stable performance and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

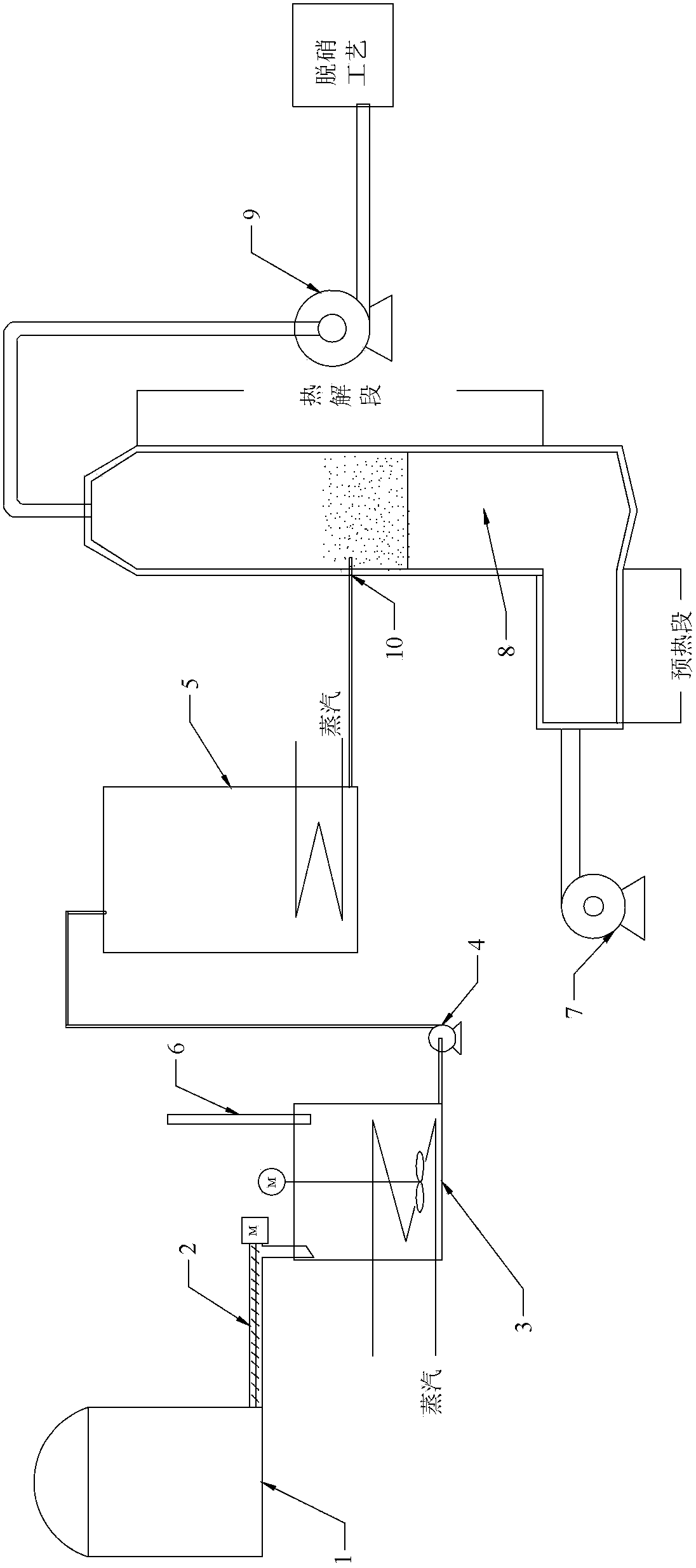

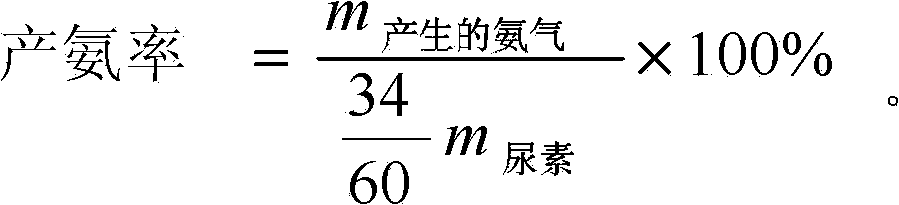

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Fe / TiO 2 / ZSM-5 catalyst (catalyst A)

[0040] In order to prepare 50g of catalyst A, ZSM-5 molecular sieve (provided by Shandong Qilu Huaxin High-Tech Co., Ltd.) was vacuum-dried in a vacuum oven at 60°C for 4 hours, cooled to room temperature, and set aside; 1ml of pure titanium tetrachloride solution ( Main agent TiO 2 Precursor) was added dropwise into 450ml dispersion liquid (48.5g ZSM-5 molecular sieve dispersed in 450ml deionized water), stirred in a water bath at 70°C, the hydrolysis time was 45min, and the pH was controlled at 1.0. Rinse with water until the pH value is about 7.0, then put the molecular sieve loaded with the main agent into a muffle furnace for calcination to 300°C, keep it warm for 5 minutes, cool to room temperature, and set aside; Immerse in 50ml ferric nitrate solution (Fe precursor, containing 0.5g iron) for 12 hours at room temperature, vacuum dry at 60°C for 4 hours in a vacuum oven, then bake at 300°C in a muffle furnace fo...

Embodiment 2

[0044] Example 2: Pt / TiO 2 / ZSM-5 catalyst (catalyst B)

[0045] In order to prepare 50g of catalyst B, ZSM-5 molecular sieve (provided by Shandong Qilu Huaxin High-Tech Co., Ltd.) was dried in a constant temperature drying oven at 100°C for 8 hours, cooled to room temperature, and set aside; 1.5ml was pure titanium tetrachloride solution (mainly TiO 2 Precursor) was added dropwise into 450ml dispersion liquid (48.5g ZSM-5 molecular sieve dispersed in 450ml deionized water), stirred in 80°C water bath, hydrolysis time was 60min, pH was controlled at 3.0, after the dropwise addition, filtered, and repeatedly deionized Rinse with water until the pH value is about 7.0, then put the molecular sieve loaded with the main agent into a muffle furnace for calcination to 450°C, keep it warm for 5 minutes, cool to room temperature, and set aside; Immerse in 50ml of chloroplatinic acid solution (Pt precursor, containing platinum 0.005g) for 16 hours at room temperature, dry in a constan...

Embodiment 3

[0047] Embodiment 3: Fe-Pt / TiO 2 / ZSM-5 catalyst (catalyst C)

[0048] In order to prepare 50g of catalyst C, ZSM-5 molecular sieve (provided by Shandong Qilu Huaxin High-Tech Co., Ltd.) was vacuum-dried in a vacuum oven at 70°C for 4 hours, cooled to room temperature, and set aside; Ti(OC 4 h 9 ) 4 load, the 10.625gTi(OC 4 h 9 ) 4 Dissolve in ethanol, add acetic acid while stirring, add ethanol containing deionized water and stir, add nitric acid dropwise to make the pH value 4, impregnate 48.5g molecular sieves in the obtained sol for 30min and pull it up. Then put the molecular sieve loaded with the main agent into a muffle furnace and calcined to 400 ° C, keep it warm for 5 minutes, cool to room temperature, and set aside; use the equal volume impregnation method to impregnate the molecular sieve loaded with the main agent step by step at room temperature according to volume, Immerse in the mixed solution of 50ml ferric nitrate (Fe precursor, containing iron 0.5g) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com