Moisture-absorbing expansion grouting mortar and its preparation method and its application in the construction of adjustable step height prefabricated stairs

A moisture-proof and mortar technology, applied in stairs, treads, stepped structures, etc., can solve the problems affecting the construction quality and pouring quality of prefabricated stairs, poor stability of drying shrinkage volume, and inability of expansion agents to work, and achieve stable construction performance. and volume stability, improve volume stability, and solve the effect of shrinkage cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The present invention also proposes a preparation method of moisture-absorbing expansion grouting mortar, which comprises the following steps:

[0070] Weigh the raw materials according to the aforementioned materials and proportions of the moisture-proof expansion grouting mortar, and mix them uniformly to obtain the moisture-proof expansion grouting mortar, which is a dry-mix composition.

[0071] The present invention also proposes an application of the moisture-insulating expansion grouting mortar prepared according to the aforementioned method in field installation of adjustable step height prefabricated stairs.

[0072] Preferably, it includes the following steps: adding water to the dry mix composition, stirring, and pouring.

[0073] Preferably, when the above-mentioned absolute moisture expansion grouting mortar is used in practice, 10-12% of its mass of water needs to be added and stirred by a mixer with a linear speed of 6-10 m / s for 3-5 minutes.

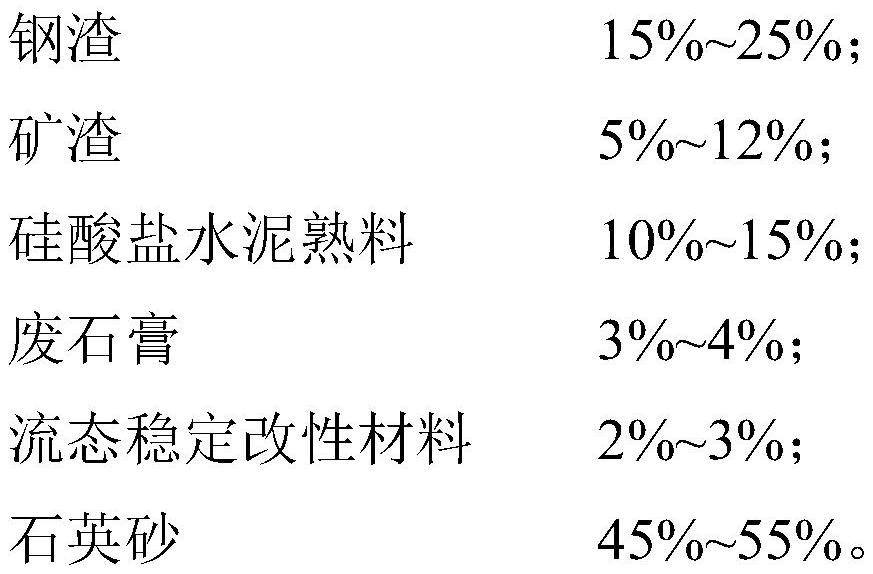

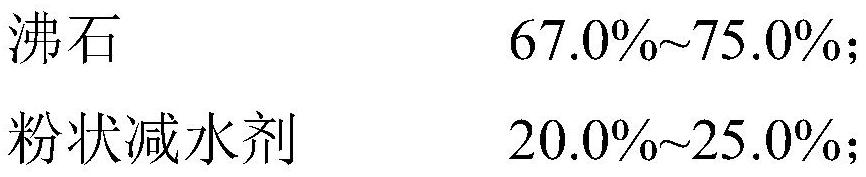

Embodiment 1~5

[0076] Weigh the raw materials according to the formula shown in Attached Table 1 and Attached Table 2, mix the various raw materials evenly, and add them to the mortar mixer together with water, wherein the weight of the added water accounts for 11.0% of the perfusion mortar dry mix composition, and the stirring blade The linear speed is 8m / s, and the rapid stirring is 4 minutes, and the moisture-absorbing grouting mortar with high fluidity, early strength and fast hardening, and no shrinkage can be obtained.

[0077] Among them, the mass percentage ratio of the three-stage gradation of quartz sand is 30.0% of 20-40 mesh quartz sand, 40.0% of 40-70 mesh quartz sand, and 30.0% of 70-120 mesh quartz sand.

[0078] According to GB / T 50448-2015 "Technical Specifications for Application of Cement-Based Grouting Materials", perform performance tests such as initial fluidity, 30min fluidity, 1d compressive strength, 3d compressive strength, 28d compressive strength and 24h vertical e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com