Firing method capable of improving strength of ceramic tableware green body as well as firing kiln

A kiln and tableware technology, which is applied to a firing method for improving the strength of ceramic tableware blanks and the field of kilns, can solve the problems of difficulty in firing high-strength ceramic blanks, affecting the quality of ceramic tableware, etc. Adhesion and flexibility, avoid bubbles or cracks, improve bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

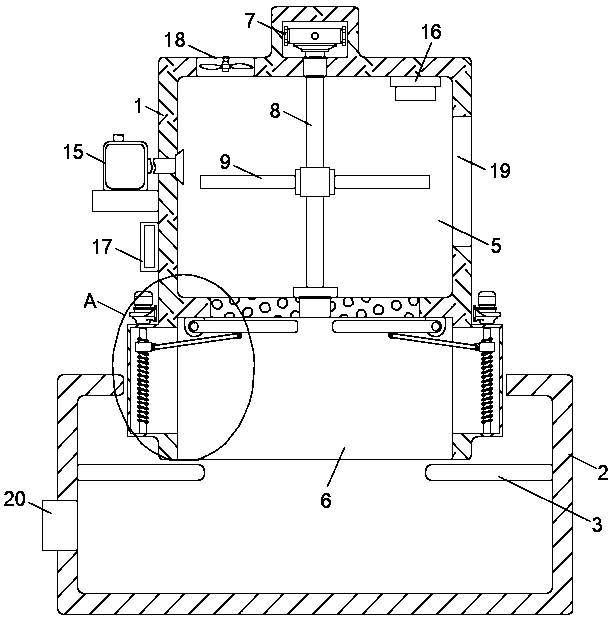

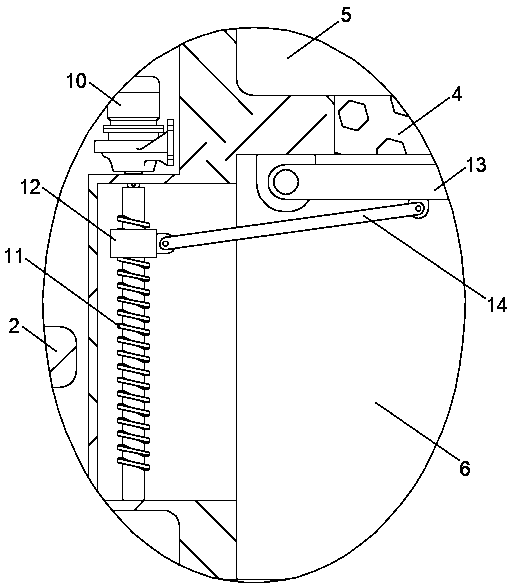

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0029] refer to Figure 1-2 , a firing method and a kiln for improving the strength of a ceramic tableware body, comprising the following steps:

[0030] S1, the ceramic tableware is placed in the firing kiln, and in the sealed state of the firing kiln, the ceramic tableware is rotated horizontally in the firing kiln at a speed of 35-40 rpm, and at the same time, the firing kiln is rotated at a speed of 0.5 -0.7°C / min speed heating, after 50-60min, keep the temperature in the firing kiln at 55-77°C;

[0031] S2, stop the fire supply and stop rotating the ceramic tableware, let it stand for 45-55 minutes until the temperature in the firing kiln is maintained at 35-40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com