High dielectric constant polyamide 6/polyphenylene ether composition and preparation method thereof

A high dielectric constant, polyamide technology, applied in the field of materials, can solve problems such as less research on high dielectric properties, and achieve the effects of improving yellowing phenomenon and thermal stability, increasing dielectric constant, and being easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

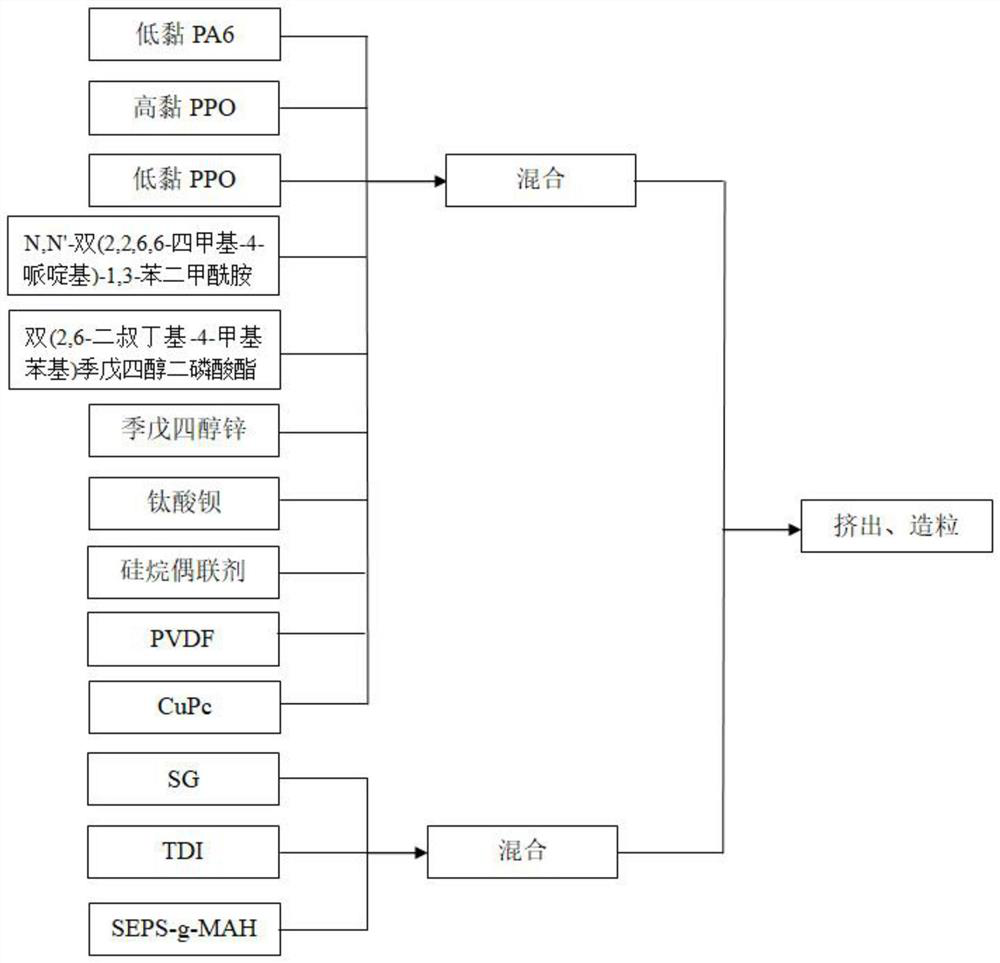

Method used

Image

Examples

Embodiment 1

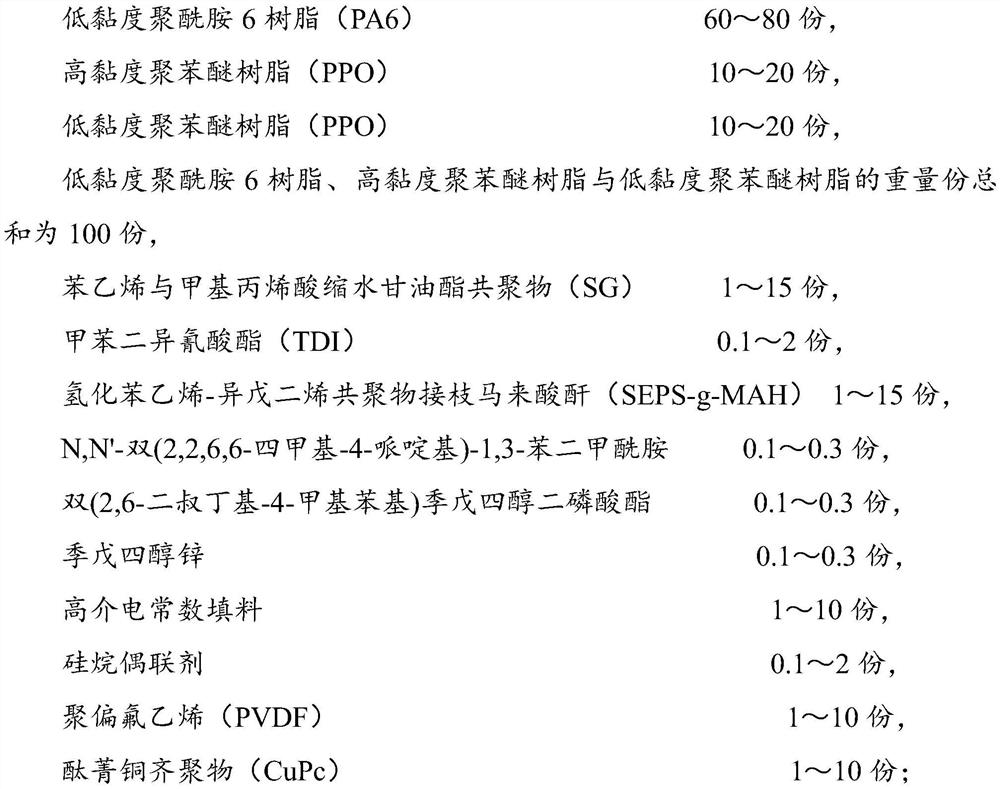

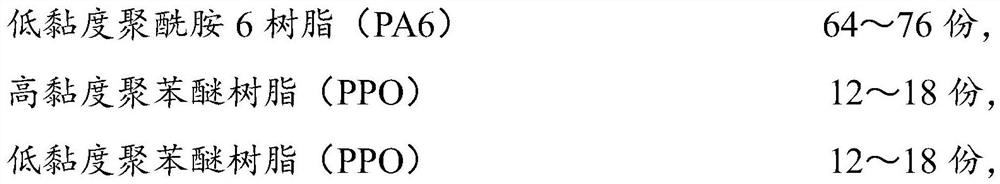

[0070] In this embodiment, a high dielectric constant polyamide 6 / polyphenylene ether composition is prepared from the following raw materials in parts by weight:

[0071]

[0072] The preparation method of above-mentioned high dielectric constant polyamide 6 / polyphenylene ether composition comprises the following steps:

[0073] (1) After drying the low-viscosity polyamide 6 resin at a temperature of 110°C for 8 hours, and drying the high-viscosity polyphenylene ether resin and low-viscosity polyphenylene ether resin at a temperature of 80°C for 8 hours , cooling, the cooled low-viscosity polyamide 6 resin, high-viscosity polyphenylene ether resin, low-viscosity polyphenylene ether resin, and the N,N'-bis(2,2,6,6-tetramethyl- 4-piperidinyl)-1,3-benzenedicarboxamide, bis(2,6-di-tert-butyl-4-methylphenyl)pentaerythritol diphosphate, zinc pentaerythritol, barium titanate, γ-aminopropyl Base triethoxysilane, polyvinylidene fluoride and copper phthalocyanine oligomers are adde...

Embodiment 2

[0078] In this embodiment, a high dielectric constant polyamide 6 / polyphenylene ether composition is prepared from the following raw materials in parts by weight:

[0079]

[0080]

[0081] The preparation method of above-mentioned high dielectric constant polyamide 6 / polyphenylene ether composition comprises the following steps:

[0082] (1) After drying the low-viscosity polyamide 6 resin at a temperature of 140°C for 4 hours, and drying the high-viscosity polyphenylene ether resin and low-viscosity polyphenylene ether resin at a temperature of 110°C for 4 hours , cooling, the cooled low-viscosity polyamide 6 resin, high-viscosity polyphenylene ether resin, low-viscosity polyphenylene ether resin, and the N,N'-bis(2,2,6,6-tetramethyl- 4-piperidinyl)-1,3-benzenedicarboxamide, bis(2,6-di-tert-butyl-4-methylphenyl)pentaerythritol diphosphate, zinc pentaerythritol, barium titanate, γ-aminopropyl Base trimethoxysilane, polyvinylidene fluoride and copper phthalocyanine olig...

Embodiment 3

[0087] In this embodiment, a high dielectric constant polyamide 6 / polyphenylene ether composition is prepared from the following raw materials in parts by weight:

[0088]

[0089]

[0090] The preparation method of above-mentioned high dielectric constant polyamide 6 / polyphenylene ether composition comprises the following steps:

[0091] (1) After drying the low-viscosity polyamide 6 resin at a temperature of 120°C for 6 hours, and drying the high-viscosity polyphenylene ether resin and low-viscosity polyphenylene ether resin at a temperature of 90°C for 6 hours , cooling, the cooled low-viscosity polyamide 6 resin, high-viscosity polyphenylene ether resin, low-viscosity polyphenylene ether resin, and the N,N'-bis(2,2,6,6-tetramethyl- 4-piperidinyl)-1,3-benzenedicarboxamide, bis(2,6-di-tert-butyl-4-methylphenyl)pentaerythritol diphosphate, zinc pentaerythritol, barium titanate, γ-aminopropyl Base triethoxysilane, polyvinylidene fluoride and copper phthalocyanine oligom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com