A kind of tungstate up-conversion luminescent material and its preparation method and application

A technology of luminescent materials and tungstate, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems that up-conversion luminescent materials cannot realize the regulation of luminescence performance, and achieve the effect of high quenching concentration and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The embodiment of the present application also provides a preparation method of the above-mentioned tungstate up-conversion luminescent material, including the following steps:

[0042] Mix the A-containing compound, Er-containing compound, Yb-containing compound and W-containing compound according to the element molar ratio of A: Er: Yb: W = (2-2x-2y): 2x: 2y: 3. After mixing evenly, carry out Pre-calcining, then grinding, calcining the ground powder, cooling and grinding again to obtain the tungstate up-conversion luminescent material; wherein A is the elements Al, Bi, Y, Lu, La, Gd and Dy One or more of them, 0<x+y<1.

[0043] Preferably, 0

[0044] The general chemical formula of the above-mentioned tungstate up-conversion luminescent material is A 2-2x-2y Er 2x Yb 2y W 3 o 12 .

[0045] Wherein the A-containing compound, the Er-containing compound, the Yb-containing compound and the W-containing compound are ...

Embodiment 1

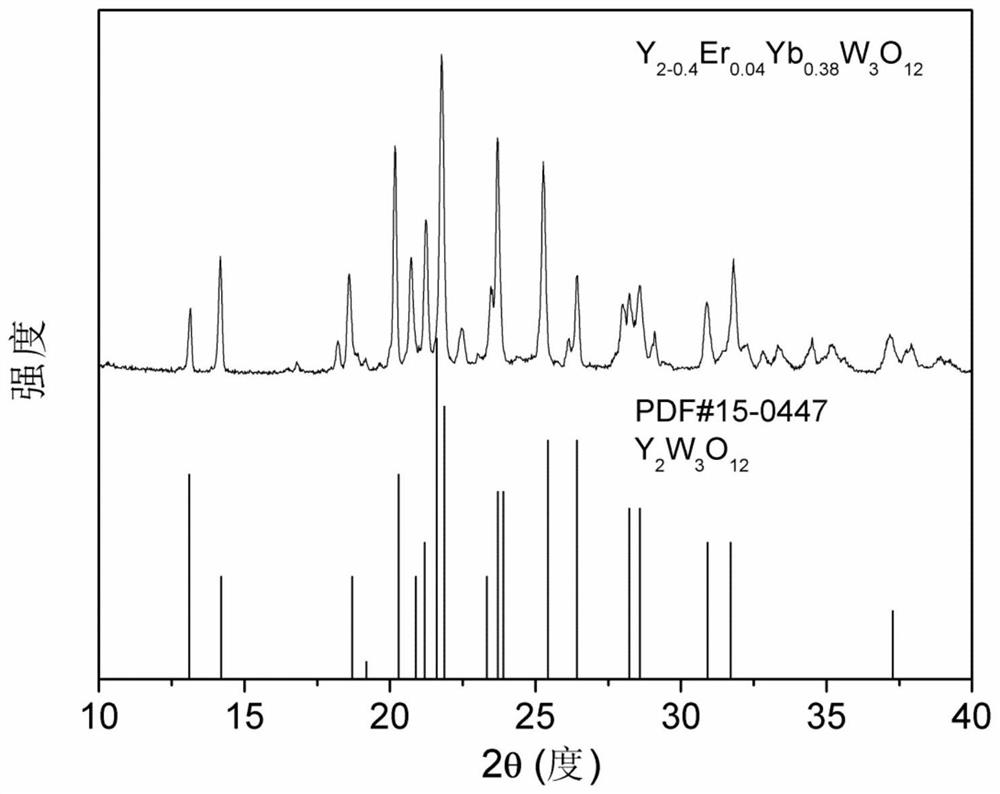

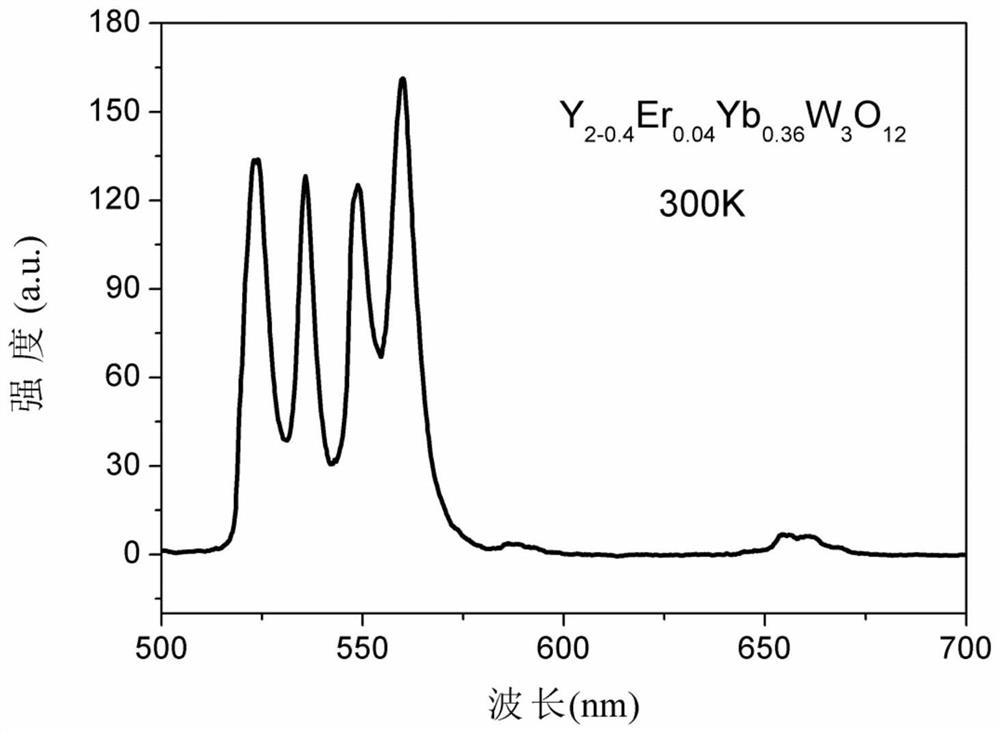

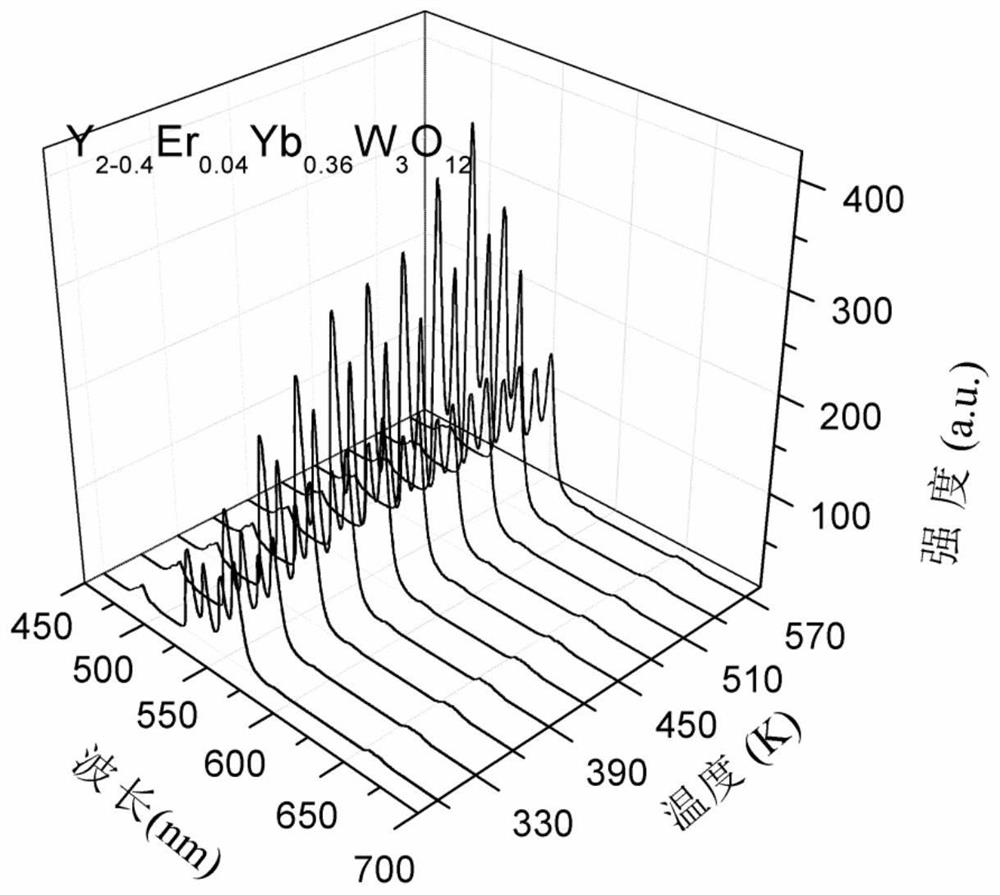

[0053] (1) According to chemical formula Y 2-0.4 Er 0.04 Yb 0.36 W 3 o 12 The stoichiometric ratio of Y, Er, Yb and W in Y, weigh Y 2 o 3 , Yb 2 o 3 , WO 3 and Er 2 o 3 The corresponding quality, the purity of these raw materials is 99.99%, grind 2-3 times with absolute ethanol, make it mix evenly;

[0054] (2) Place the ground sample in an oven at 80°C for two hours to dry, then put it into a corundum boat, then put the corundum boat with the sample into a high-temperature furnace for pre-burning, and keep it warm at 500°C in an air atmosphere 6 hours, then naturally cool down to normal temperature;

[0055] (3) Take out the sample from the high-temperature furnace, grind it with alcohol for 2-3 times, and dry it;

[0056] (4) Put the dried sample into a corundum boat, put it into a high-temperature furnace for calcination, slowly raise the temperature to 1100°C in an air atmosphere, keep it warm for 6 hours, then cool naturally, and finally grind to obtain tungst...

Embodiment 2

[0065] (1) According to the chemical formula Lu 2-0.4 Er 0.04 Yb 0.36 W 3 o 12 The stoichiometric ratio of Lu, Er, Yb and W in Lu, weighed Lu 2 o 3 , Yb 2 o 3 , WO 3 and Er 2 o 3 The corresponding quality and the purity of these raw materials are all 99.99%, and they are ground 2-3 times with absolute ethanol to make them evenly mixed.

[0066] (2) Place the ground sample in an oven at 80°C for two hours to dry, then put it into a corundum boat, then put the corundum boat with the sample into a high-temperature furnace for pre-burning, and keep it warm at 500°C in an air atmosphere 6 hours, then cool down to normal temperature naturally.

[0067] (3) Take out the sample from the high-temperature furnace, grind it with alcohol for 2-3 times, and then dry it.

[0068] (4) Put the dried sample into a corundum boat, put it into a high-temperature furnace for calcination, slowly raise the temperature to 1150°C in an air atmosphere, keep it warm for 6 hours, then cool na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com