A kind of red fluorescent powder with high doping concentration and preparation method thereof

A technology of red phosphor and high doping concentration, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of expensive rare earth elements, low quenching concentration, and poor thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh Ca(NO 3 ) 2 4H 2 O (analytical pure) 0.647g, Sr (NO 3 ) 2 (Analytical Pure) 0.387g, (NH 4 ) 6 Mo 7 o 24 4H 2 O (analytical pure) 0.806g, the above-mentioned raw materials are accurately weighed. Then, various nitrates and ammonium molybdate tetrahydrate are dissolved in deionized water. For nitrates with low solubility, a small amount of dilute nitric acid can be added dropwise to the solution to promote dissolution, while stirring with a magnetic stirrer. After it is completely dissolved, add 1mol / L sodium hydroxide solution or potassium hydroxide solution dropwise to the clear liquid, adjust the pH value to 9-10, stop adding lye, continue stirring and add heat for 30 minutes (the purpose is to ensure that the precipitation reaction is complete), molybdate precipitation no longer increases, stop stirring and heating. After the particle precipitate in the solution is completely precipitated, remove the supernatant, add 250ml of deionized water to wash, a...

Embodiment 2

[0022] Weigh Ca(NO 3 ) 2 4H 2 O (analytical pure) 0.413g, Sr (NO 3 ) 2 (Analytical pure) 0.556g, (NH 4 ) 6 Mo 7 o 24 4H 2 O (analytically pure) 0.772g, the above raw materials are accurately weighed. Then, various nitrates and ammonium molybdate tetrahydrate are dissolved in deionized water. For nitrates with low solubility, a small amount of dilute nitric acid can be added dropwise to the solution to promote dissolution, while stirring with a magnetic stirrer. After it is completely dissolved, add 1mol / L sodium hydroxide solution or potassium hydroxide solution dropwise to the clear liquid, adjust the pH value to 9-10, stop adding lye, continue stirring and add heat for 30 minutes (the purpose is to ensure that the precipitation reaction is complete), molybdate precipitation no longer increases, stop stirring and heating. After the particle precipitate in the solution is completely precipitated, remove the supernatant, add 250ml of deionized water to wash, and repea...

Embodiment 3

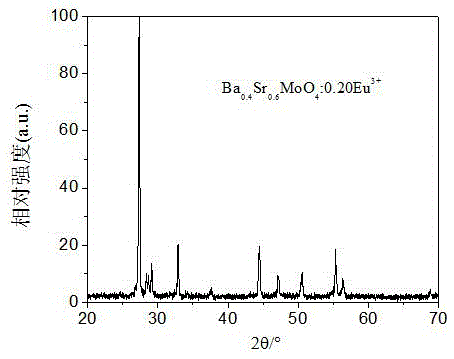

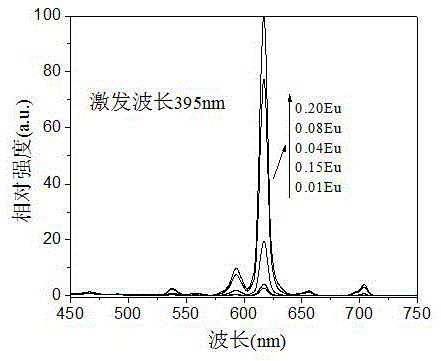

[0025] Weigh Ba(NO 3 ) 2 (Analytical pure) 0.848g, Sr(NO 3 ) 2 (Analytical pure) 0.458g, (NH 4 ) 6 Mo 7 o 24 4H 2 O (analytical pure) 0.955g, the above-mentioned raw materials are accurately weighed. Then, various nitrates and ammonium molybdate tetrahydrate are dissolved in deionized water. For nitrates with low solubility, a small amount of dilute nitric acid can be added dropwise to the solution to promote dissolution, while stirring with a magnetic stirrer. After it is completely dissolved, add 1mol / L sodium hydroxide solution or potassium hydroxide solution dropwise to the clear liquid, adjust the pH value to 9-10, stop adding lye, continue stirring and add heat for 30 minutes (the purpose is to ensure that the precipitation reaction is complete), molybdate precipitation no longer increases, stop stirring and heating. After the particle precipitate in the solution is completely precipitated, remove the supernatant, add 250ml of deionized water to wash, and repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com