Non-displacement pile foundation construction method adopting sediment gelation

A construction method and gelling technology, which can be used in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of cumbersome on-site management, different production volumes, and reduced manufacturing efficiency, and achieve economical, high manufacturing efficiency, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and preferred embodiments.

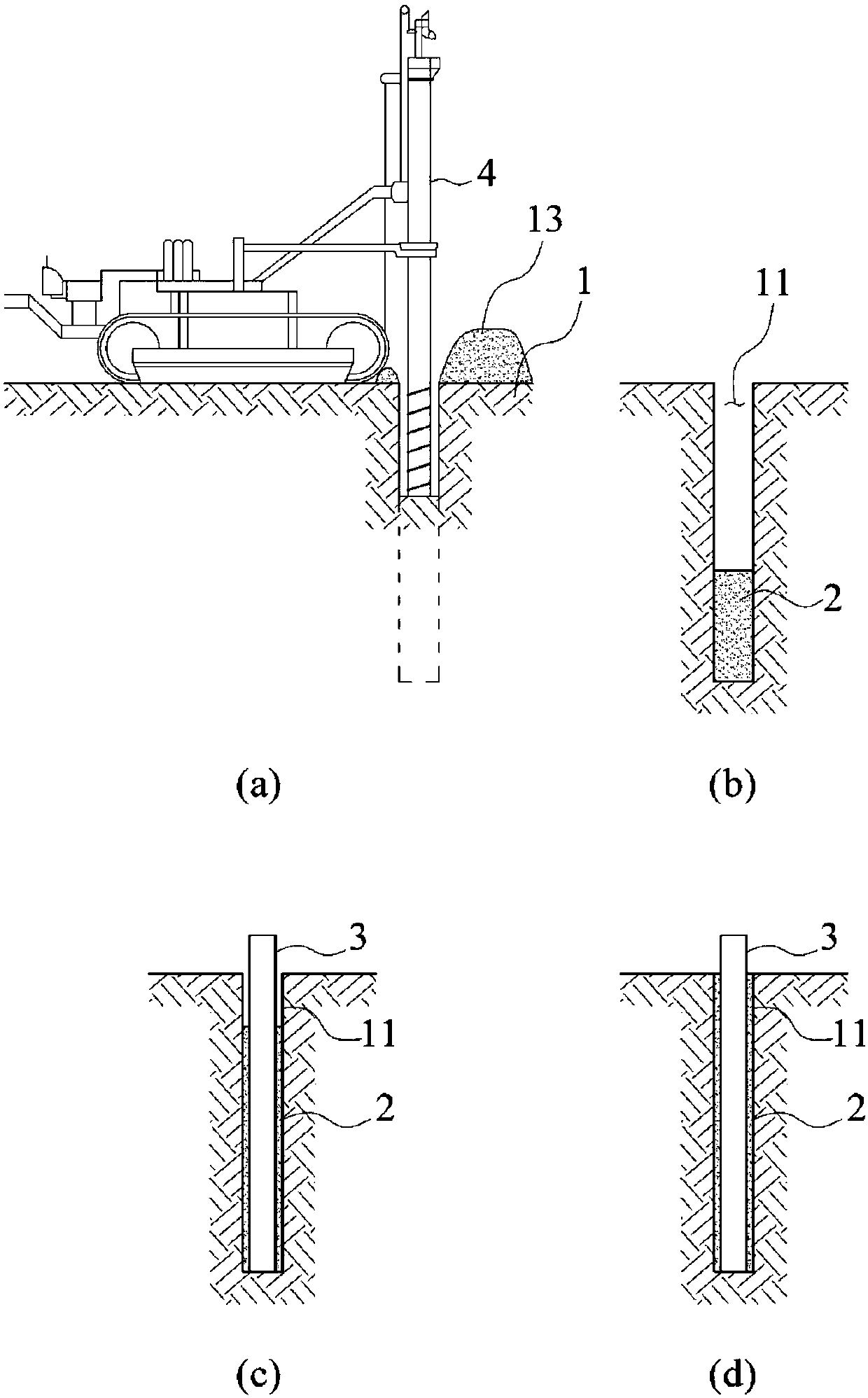

[0097] figure 2 It is a drawing showing the process of each step of the non-discharge pile foundation construction method through the sediment gelation of the present invention.

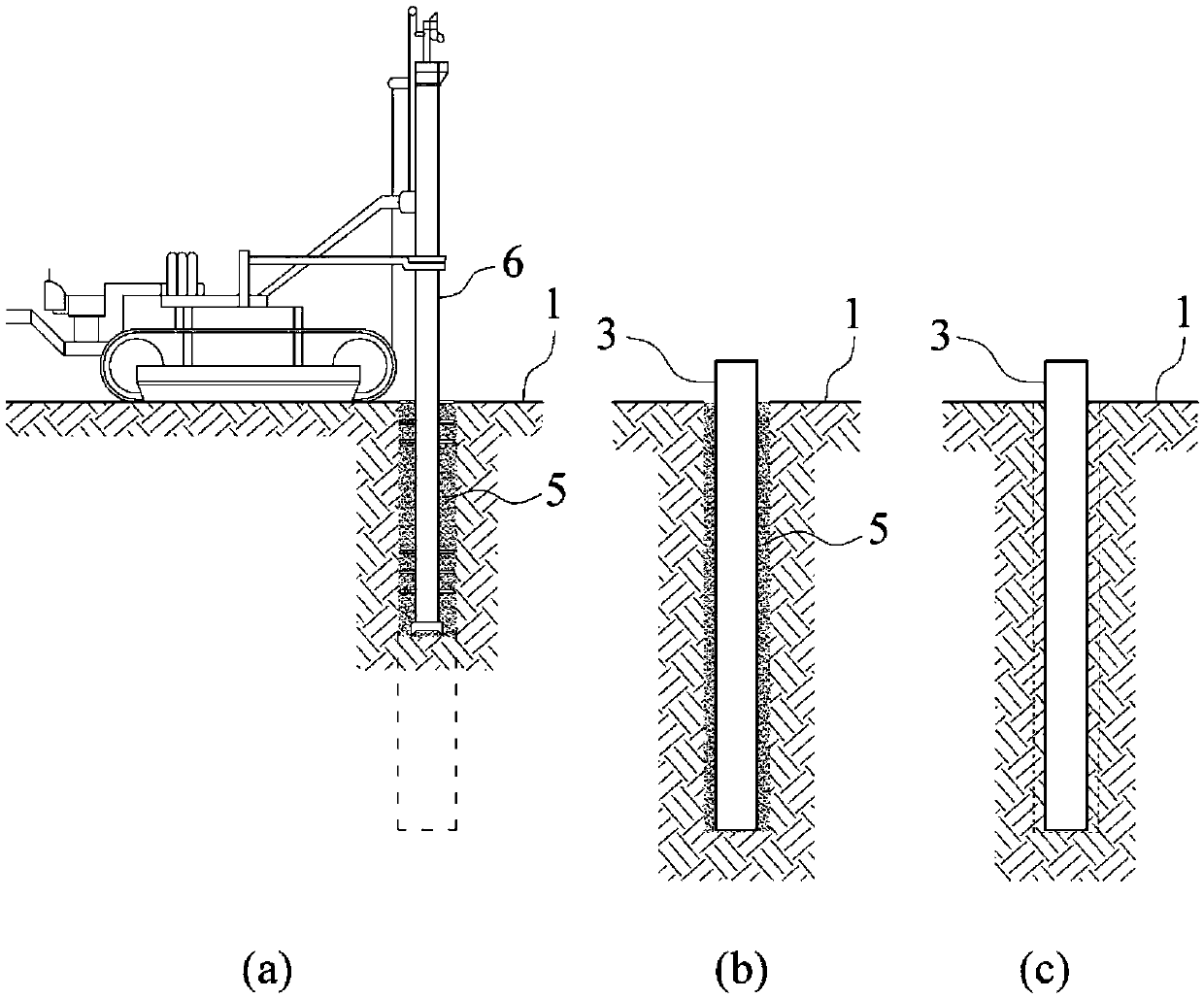

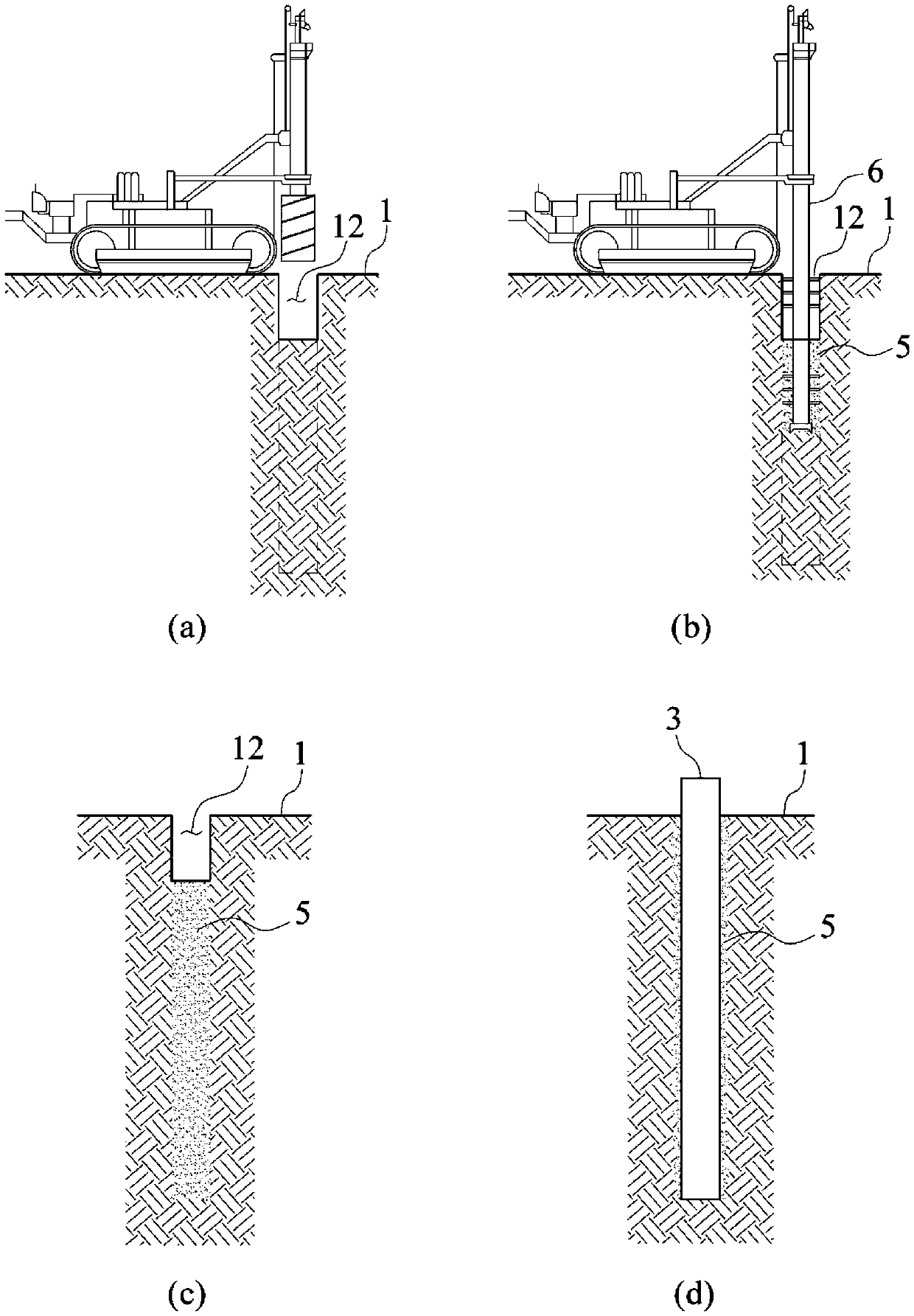

[0098] Such as figure 2 As shown, according to the non-discharge pile foundation construction method of sediment gelation of the present invention, in order to penetrate the pile body 3 at the foundation 1, it includes: (a) the step of measuring the position of the pile body 3 to be constructed; (b) Rotate and penetrate the stirring device 6 at the construction site of the pile body 3 until the foundation is supported, so that the silt in the foundation 1 is softened, and the gelling agent is sprayed to the stirring device 6, and the softened silt is mixed with the gelling agent. stirring to make the sediment gel (gel); (c) remove the stirring device 6, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com