Water jet braiding machine ceramic ball one-way valve

A ceramic ball and one-way valve technology, which is applied to lift valves, valve details, control valves, etc., can solve problems such as affecting the start-up efficiency of the water jet knitting machine, affecting the yield of fabric quality, and poor wear resistance of the one-way valve. , to achieve the effect of simple structure, improved yield and improved boot efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings and embodiments.

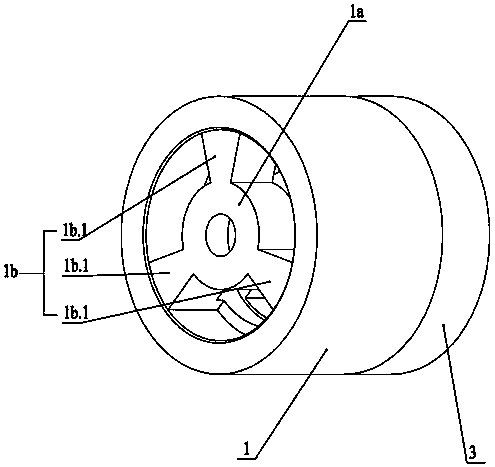

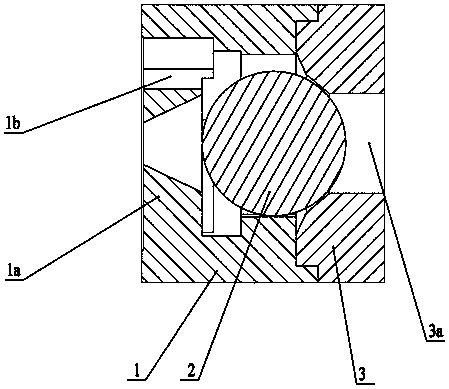

[0025] Such as figure 1 , figure 2 As shown, the embodiment discloses a ceramic ball check valve for a water jet weaving machine, which is mainly composed of a valve body 1, a sealing ball 2, a valve cover 3 and the like.

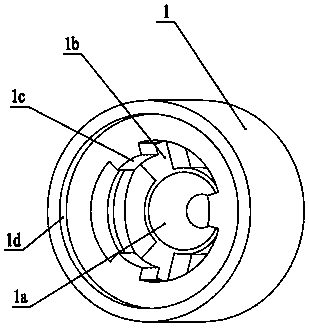

[0026] Such as Figure 1 ~ Figure 3 As shown, the inside of the valve body 1 is provided with a valve cavity, and the opening of the valve cavity is located at the top of the valve body 1; the center of the bottom of the valve body 1 is provided with a hollow water inlet pipe 1a, and the water inlet pipe 1a is connected to the valve through the connecting bracket 1b. The inner wall of the body 1 is connected, and the external high-pressure water can enter the valve cavity through the water inlet pipe 1a; the sealing ball 2 is movable in the valve cavity, the valve cover 3 is fixedly connected to the top of the valve body 1, and the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com