Vacuum drainage device of easy-open lids dividing coating machine

A technology of vacuum sewage discharge and easy-to-pull cover, which is applied to the device for coating liquid on the surface, spray device, coating, etc., can solve the problem of poor suction and sewage effect, etc., to achieve convenient cleaning, improve start-up efficiency, and shutdown maintenance. effect of time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

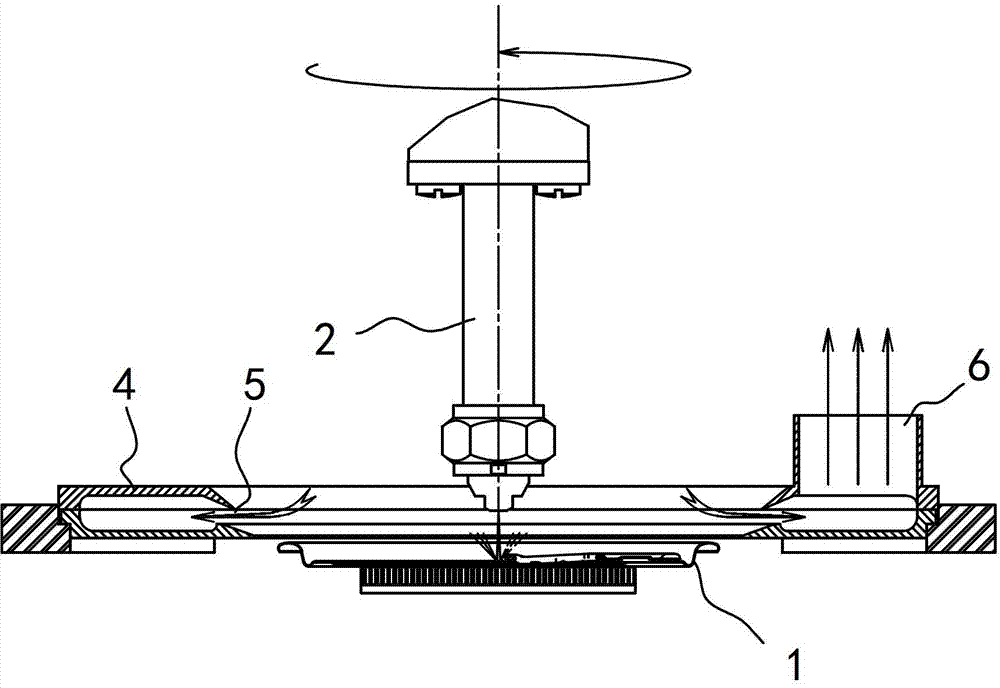

[0024] Example: see attached Figure 4-6 as shown,

[0025] A vacuum blowdown device for an easy-open lid engraved line repairing machine, which is composed of a rotary inner cover 9, a suction outer cover 10 and a suction fan (not shown in the figure).

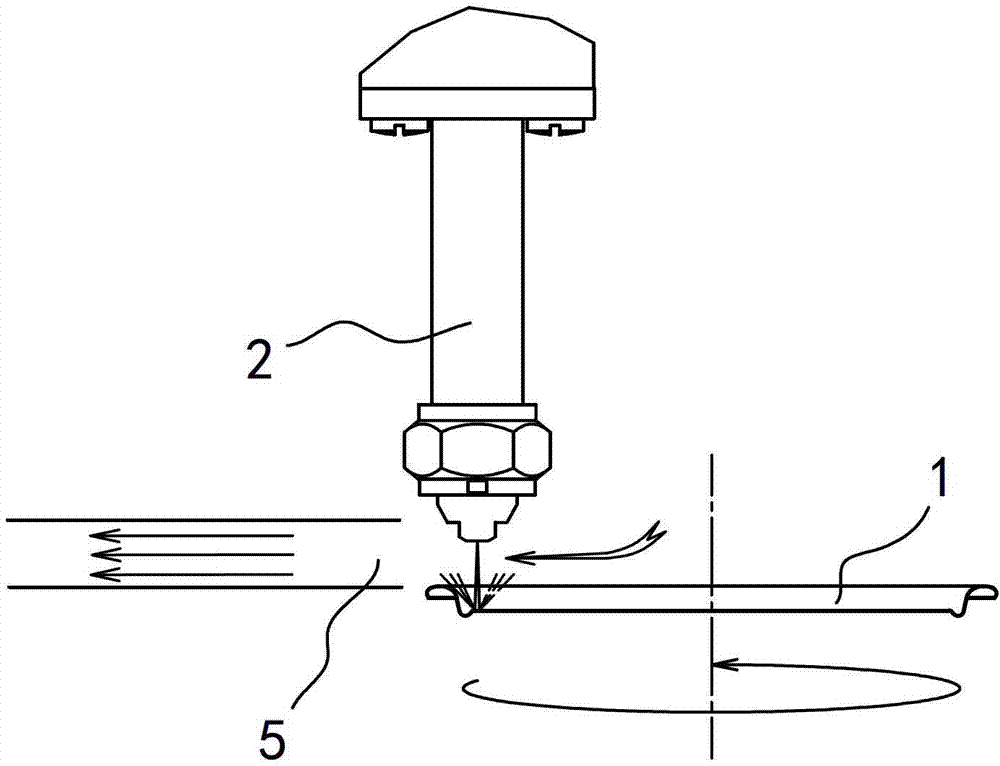

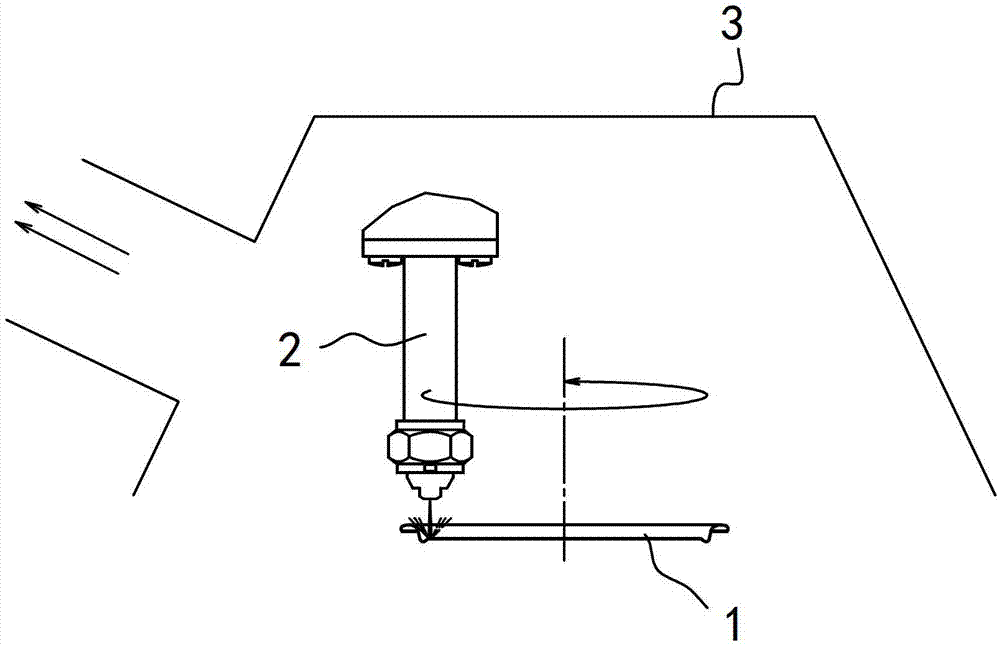

[0026] Spray gun rotating type easy-open lid re-coating machine includes machine base, rotary shaft 7, spray gun 8 rotating around the rotary shaft 7, and easy-open-cap conveying belt 16 for transporting easy-open cap 11. During use, be that easy-open lid 11 is placed in the pit of equidistant distribution of easy-open lid conveying belt 16, drives easy-open lid 11 to pass through the below of spray gun 8 successively by easy-open-lid conveying belt 16. When the easy-open cover 11 stops under the spray gun 8, the central axis of the easy-open cover 11 coincides with the center line of the circular shaft 7. After the easy-open cover 11 is confirmed to be in place, the nozzle of the spray gun 8 is opened to spray paint on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com