Hydrogen filling system having hydrogen storage vessel and method of operating same

A technology for filling systems and storage containers, applied in container filling methods, container discharge methods, gas treatment/storage purposes, etc., can solve the problems of unsuitable hydrogen storage containers, failure to replace new containers, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

[0028] The present invention is capable of many modifications and forms, of which specific embodiments will be illustrated in the drawings and described in detail herein. However, it should be understood that it is not intended to limit the present invention to a specific disclosed form, and includes all changes, equivalents and substitutes falling within the spirit and technical scope of the present invention.

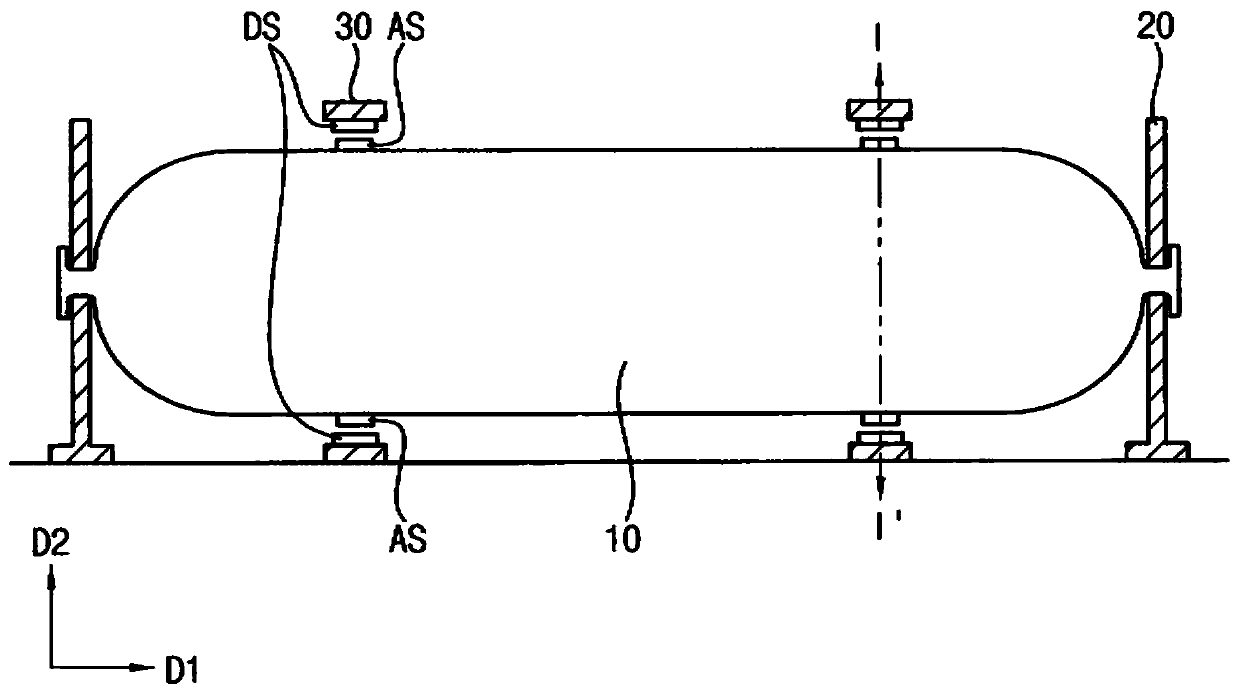

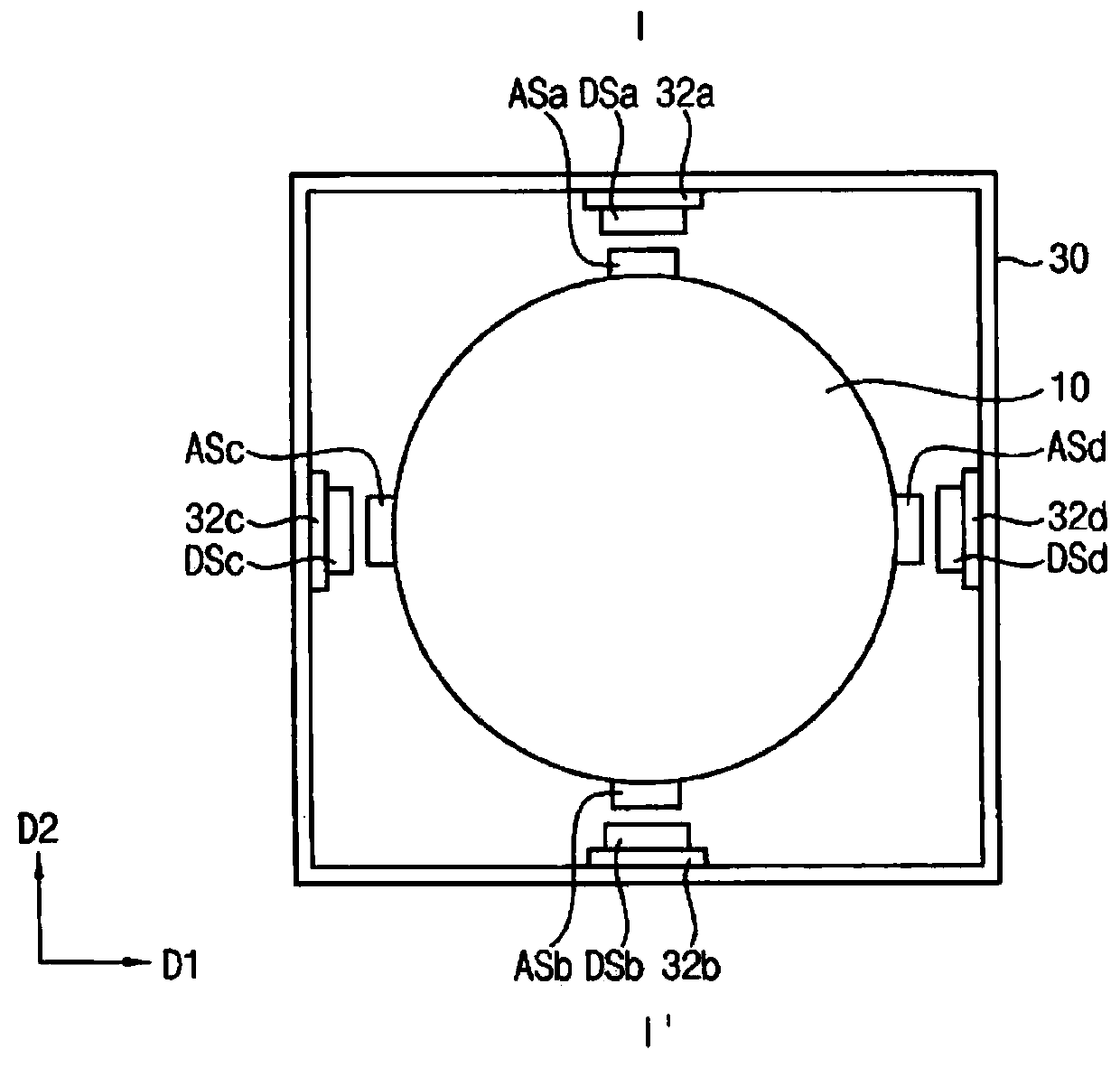

[0029] figure 1 It is a top view of a hydrogen storage container according to an embodiment of the present invention. figure 2 for along figure 1 The cross-sectional view of the hydrogen storage vessel taken by the line II'.

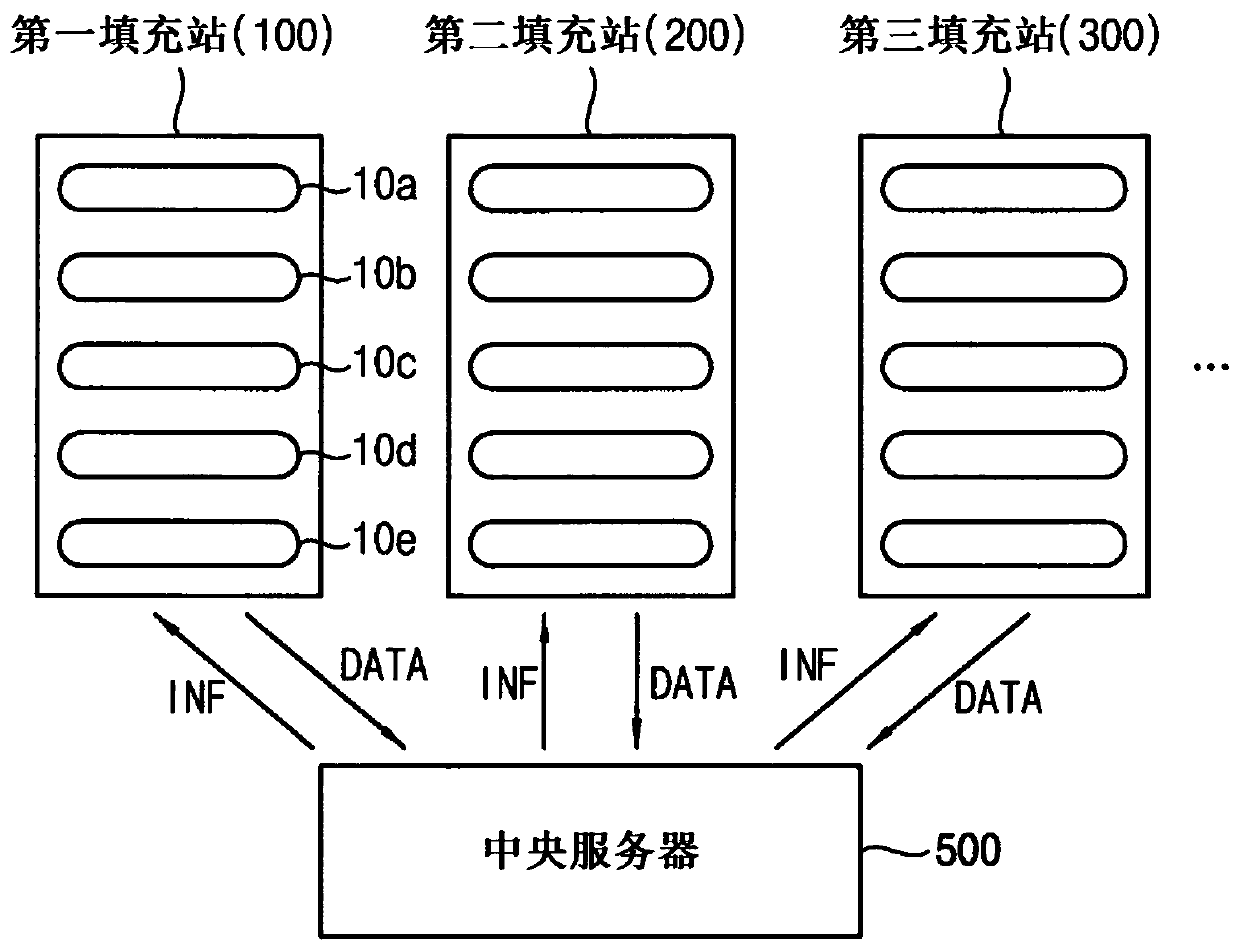

[0030] refer to figure 1 and figure 2 , the above-mentioned hydrogen storage container may include: a container 10, a support portion 20, a frame 30, a plurality of acoustic sensors (acoustic s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap