A Fuel Detection Device Based on Temperature Control

A detection device and temperature control technology, which is applied in measuring devices, testing/calibrating devices, liquid/fluid solid measurement, etc., can solve problems such as error and single value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

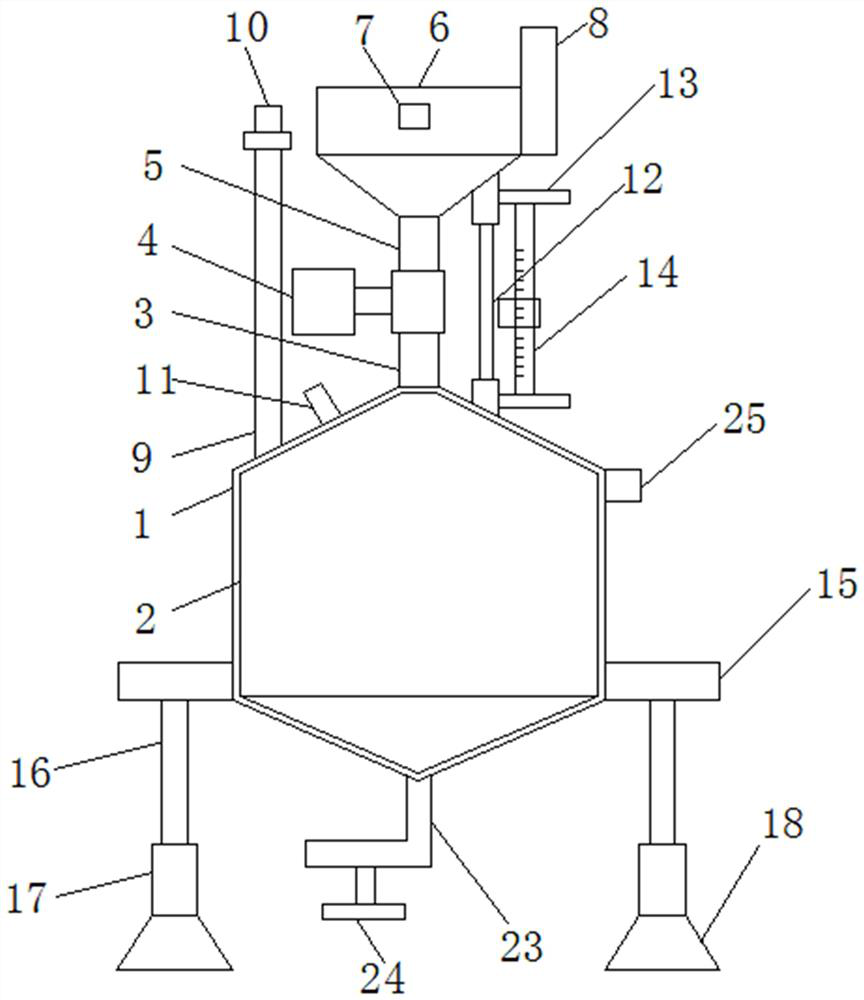

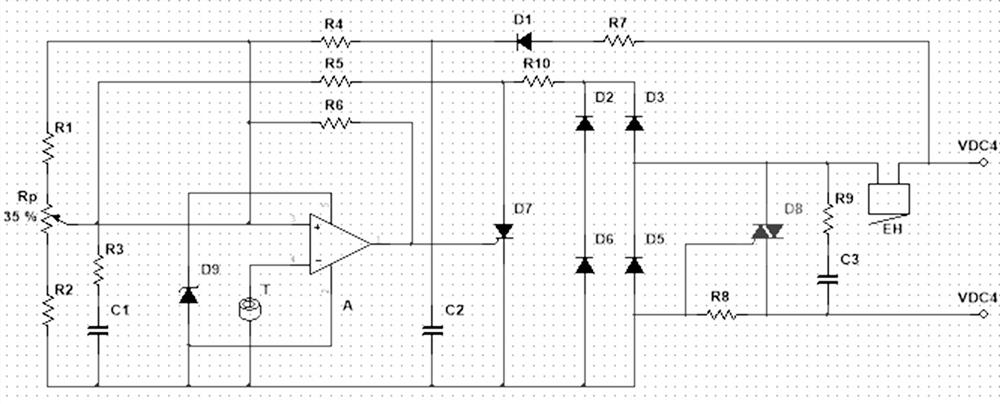

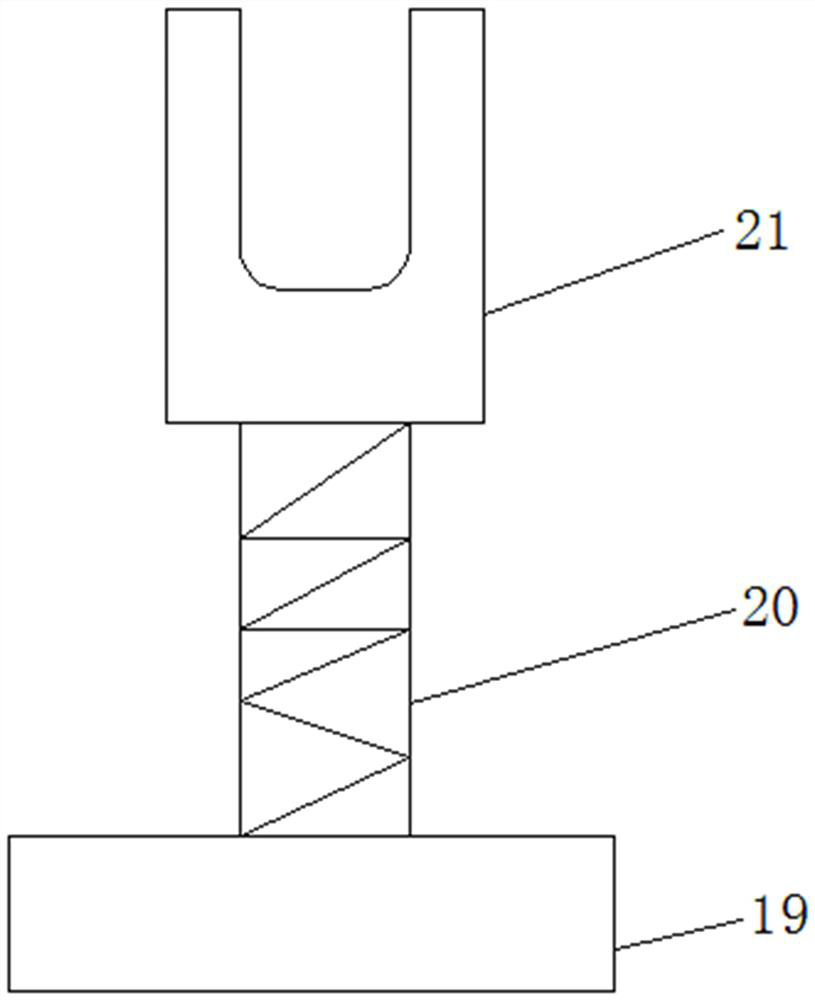

[0024] The present invention will be further described below in conjunction with specific embodiments, wherein, the accompanying drawings are only for illustrative purposes, please refer to Figure 1-Figure 4 , the present invention provides a technical solution: a fuel oil detection device based on temperature control, including a standard metal gauge 1, the surface of the inner cavity of the standard metal gauge 1 is provided with a non-stick coating 2, which can prevent the fuel from sticking The inner wall of the standard metal gauge 1 will not affect the detection result due to the combination of the oil sticky on the inner wall and the oil added again, which improves the accuracy of the data. The top of the standard metal gauge 1 is fixedly connected with a metering neck 3, The top of the metering neck 3 is sleeved with a liquid flow meter 4, which can measure the amount of fuel flowing through the metering neck, and calculate the volume through the flow rate, which can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com