A kind of r-t-b permanent magnet material, raw material composition, preparation method, application

A technology of R-T-B and permanent magnet materials, which is applied in the direction of magnetic materials, magnetic circuits characterized by magnetic materials, magnetic objects, etc., can solve the problems that Hcj and Br cannot be improved at the same time, and achieve mass production and large temperature range , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

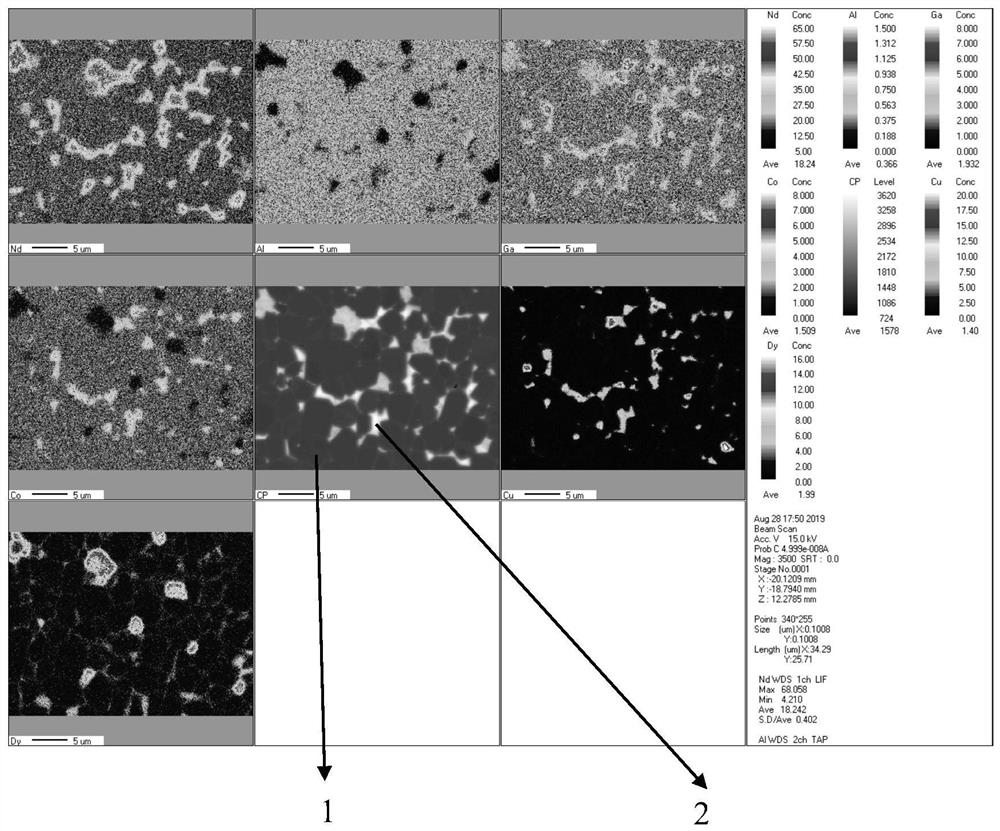

Image

Examples

Embodiment 1

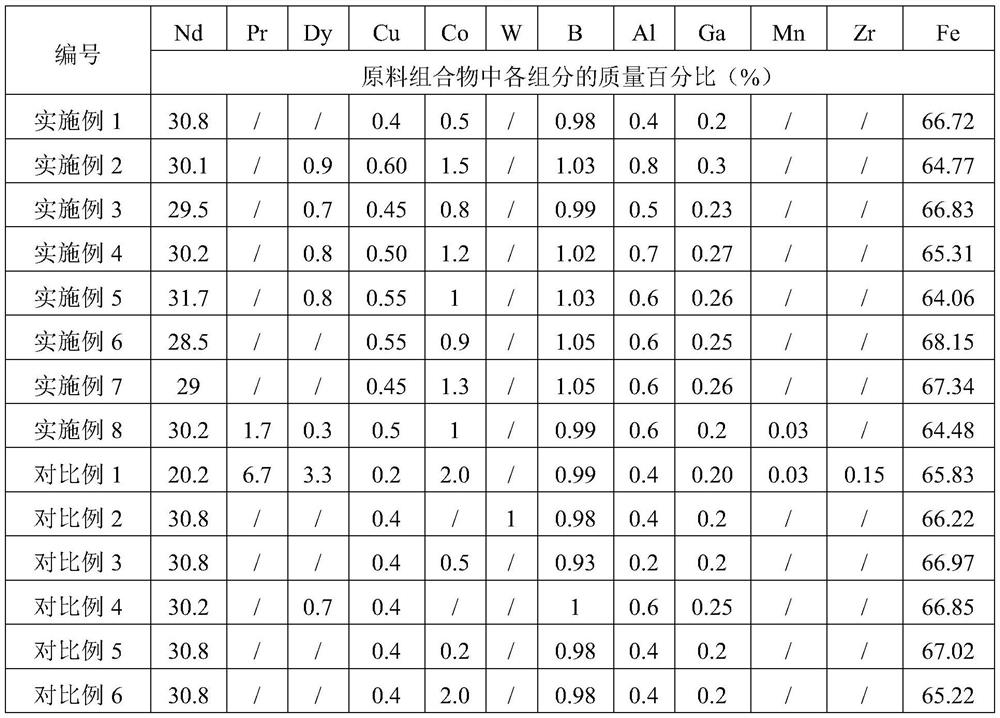

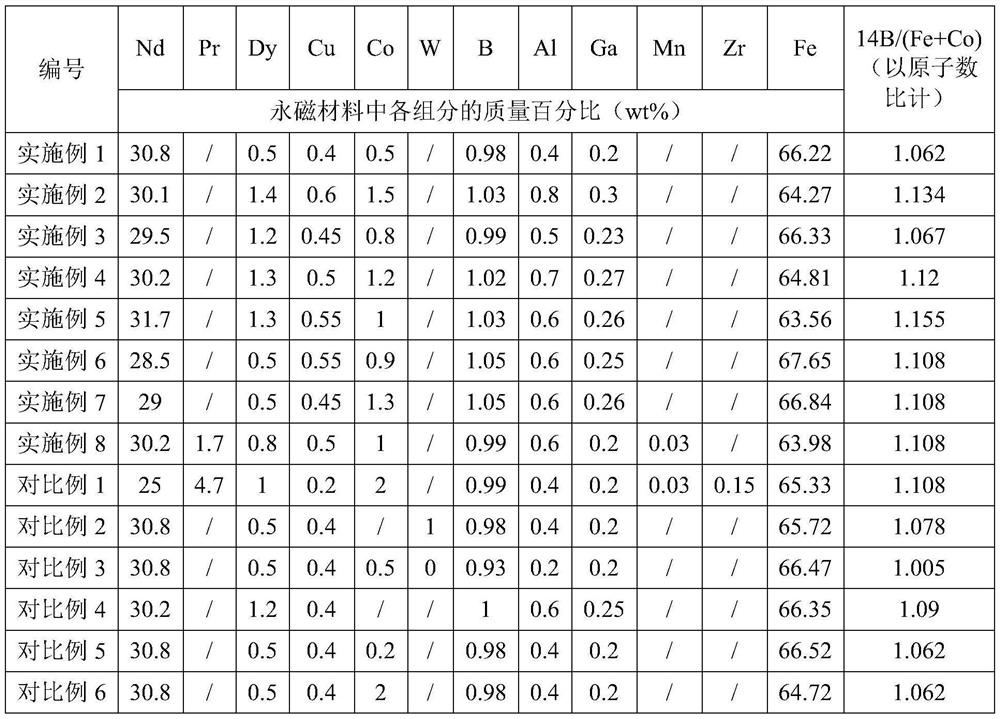

[0104] (1) casting process: the raw material composition shown in embodiment 1 in following table 1, get the composition of corresponding proportioning and put into vacuum melting furnace at 5 * 10 -2 Vacuum smelting is carried out at a temperature below 1500°C in a vacuum of Pa; and then the molten liquid obtained by smelting is cast by a strip continuous casting method to obtain an alloy sheet with a thickness of 0.2 mm.

[0105] (2) Coarse crushing process: at room temperature, place the alloy flakes in step (1) in flowing hydrogen, and carry out hydrogen adsorption treatment for 1 hour. After fully absorbing hydrogen, heat up while vacuuming, and fully dehydrogenate. The dehydrogenation treatment is carried out at ℃ for 2 hours to obtain a coarsely pulverized powder, the particle size of which is D50300 μm.

[0106] (3) Micro-grinding process: the coarsely-grinded powder in step (2) is fine-grinded using a collision-plate jet mill device in a nitrogen stream to obtain a fi...

Embodiment 3~7、 comparative example 2~3 and comparative example 5~6

[0115] The R-T-B series permanent magnet material corresponding to Embodiment 3~7, Comparative Examples 2~3 and Comparative Examples 5~6 is obtained by the raw material composition shown in Table 1, wherein, Embodiment 3~7, Comparative Examples 2~3 The preparation process of Comparative Examples 5-6 is the same as that of Example 1.

Embodiment 2、 Embodiment 8 and comparative example 1 and comparative example 4

[0117] (1) Casting process: according to the raw material composition shown in Table 1, get the raw material of corresponding ratio and put it into the vacuum melting furnace at 5×10 -2 Vacuum smelting is carried out at a temperature below 1500°C in a vacuum of Pa; and then the molten liquid obtained by smelting is cast by a strip continuous casting method to obtain an alloy sheet with a thickness of 0.3mm.

[0118] (2) Coarse crushing process: at room temperature, place the alloy flakes in step (1) in flowing hydrogen, and carry out hydrogen adsorption treatment for 2 hours. After fully absorbing hydrogen, heat up while vacuuming, and fully dehydrogenate. dehydrogenation treatment for 3 hours at °C to obtain a coarsely pulverized powder, the particle size of which is D50 400 μm.

[0119] (3) Micro-grinding process: use a collision plate jet mill device in nitrogen flow to finely pulverize the coarsely pulverized powder in step (2) to obtain a finely pulverized powder with an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com