Back film and flexible display panel

A flexible display and back film technology, applied in identification devices, instruments, electrical solid devices, etc., can solve the problems of reduced elastic recovery, reduced rigidity of the back plate in the folded area, and downward plastic deformation of the central part, so as to reduce bending stress, The effect of minimizing the possibility of permanent deformation or fracture and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

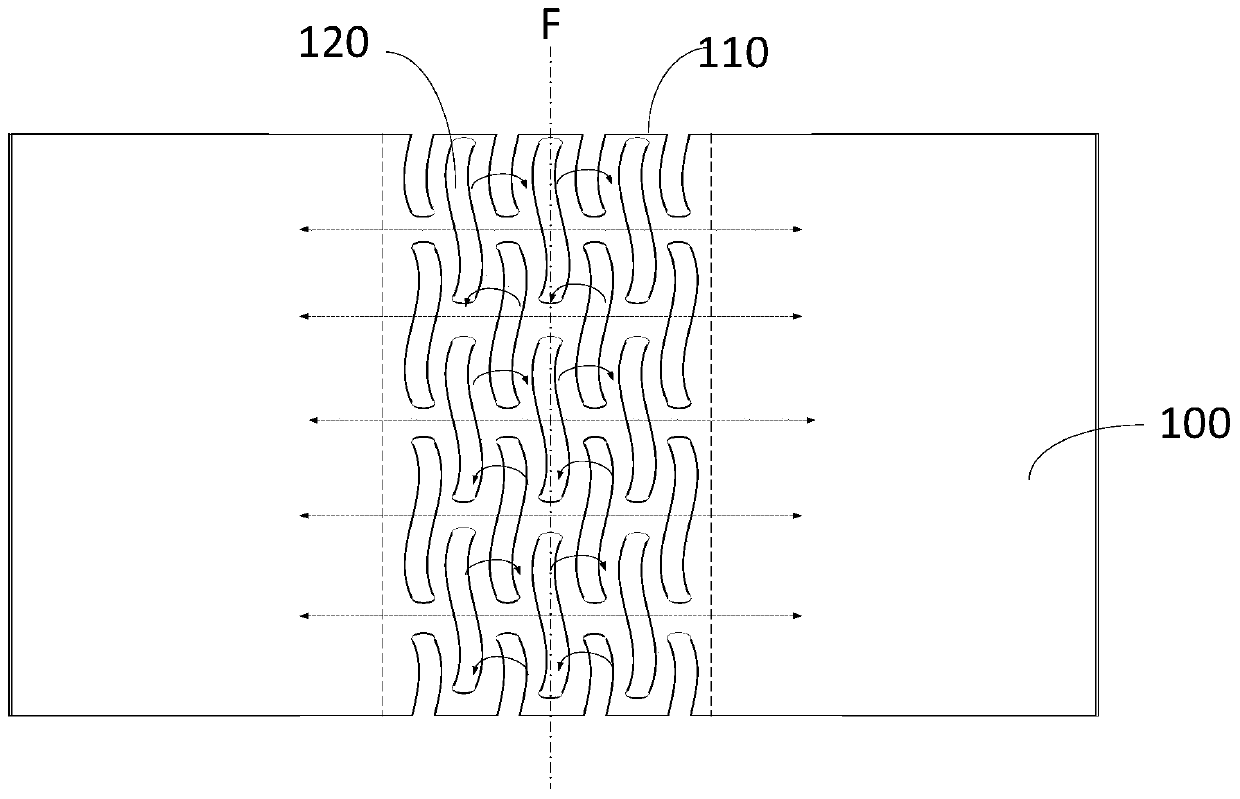

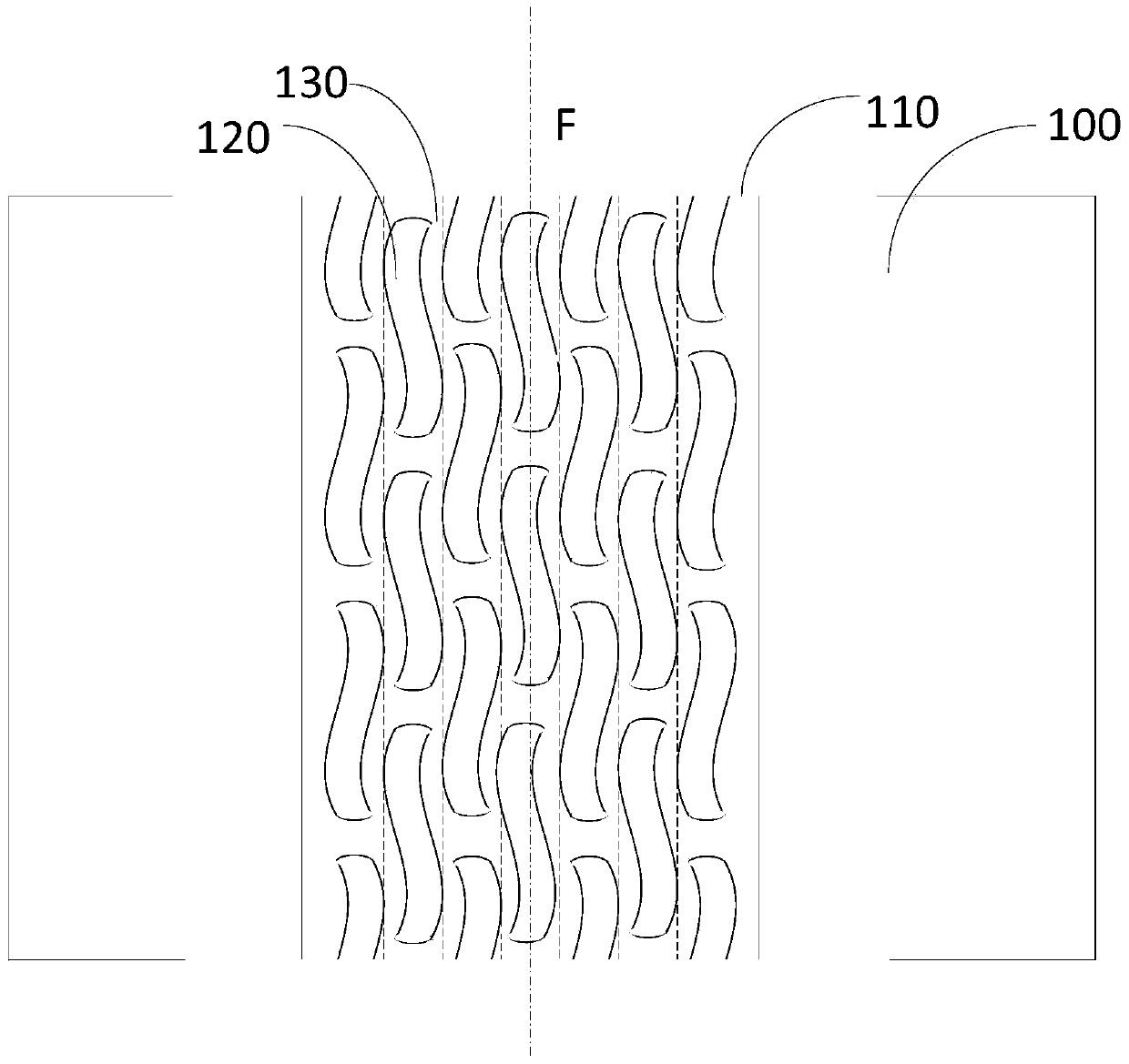

[0069] The first embodiment: the elastic filler 140 can be selected from photocurable resin or thermosetting resin. In the direction perpendicular to the bending axis of the bendable region 110, the elasticity of the elastic filler 140 The modulus gradually increases from the center of the bendable region 110 to the two side edges of the bendable region 110 .

[0070] In the above solution, by controlling the solidification degree of the elastic filler 140 in the opening units at different positions, different positions of the bendable region 110 have different elastic moduli, wherein, in the direction perpendicular to the bending axis of the bendable region 110 In the direction, the elastic modulus of the middle area of the bendable area 110 is small, and the elastic modulus of the edge areas on both sides is large. Such as Figure 15 As shown, positions A, B, and C in the figure have different curing degrees and elastic moduli (E AB C ).

[0071] Wherein, for the fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com