Device for assisting battery infiltration

An auxiliary battery and battery technology, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of high cost and long soaking time, so as to reduce production costs, improve soaking efficiency, and shorten soaking time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the embodiments and features in the embodiments of the present invention can be combined with each other.

[0036] The present invention will be described in detail below with reference to the drawings and in combination with embodiments.

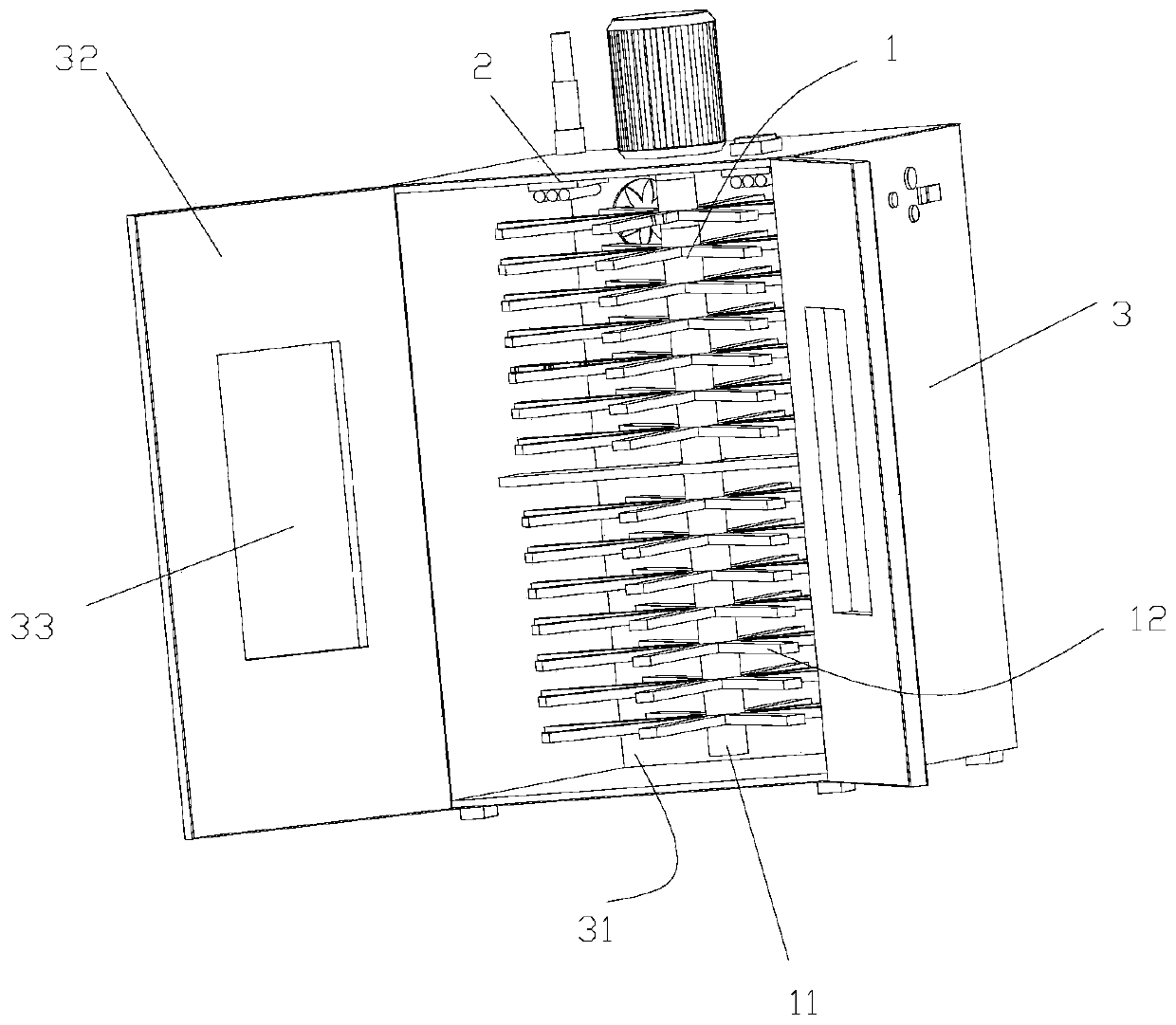

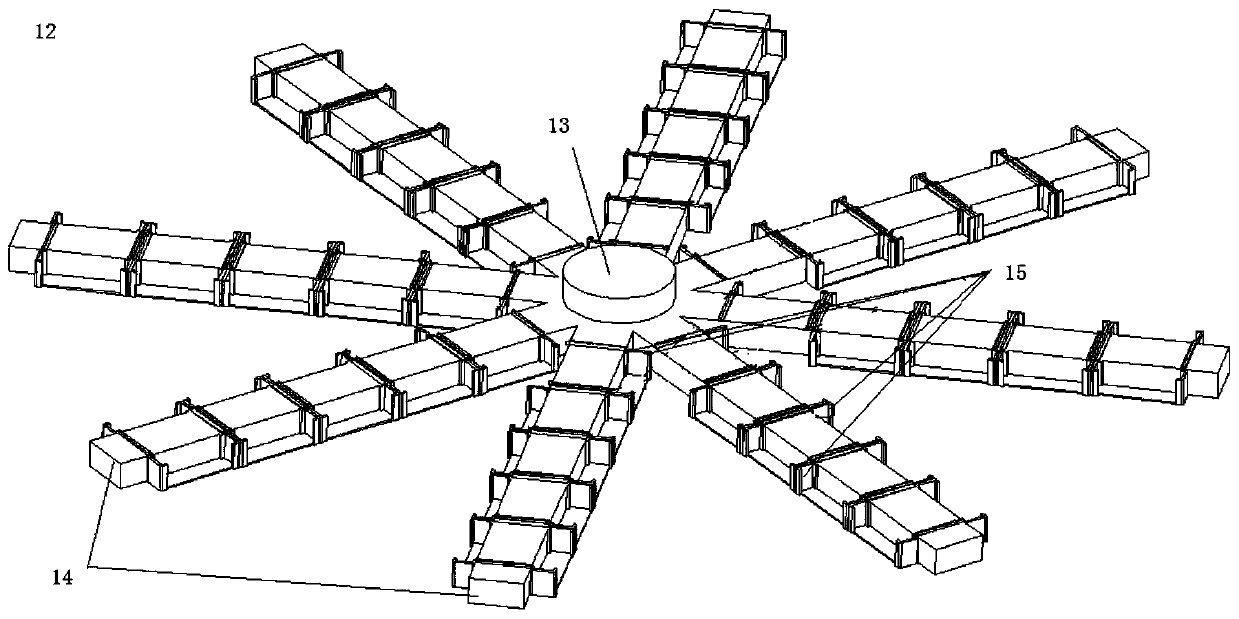

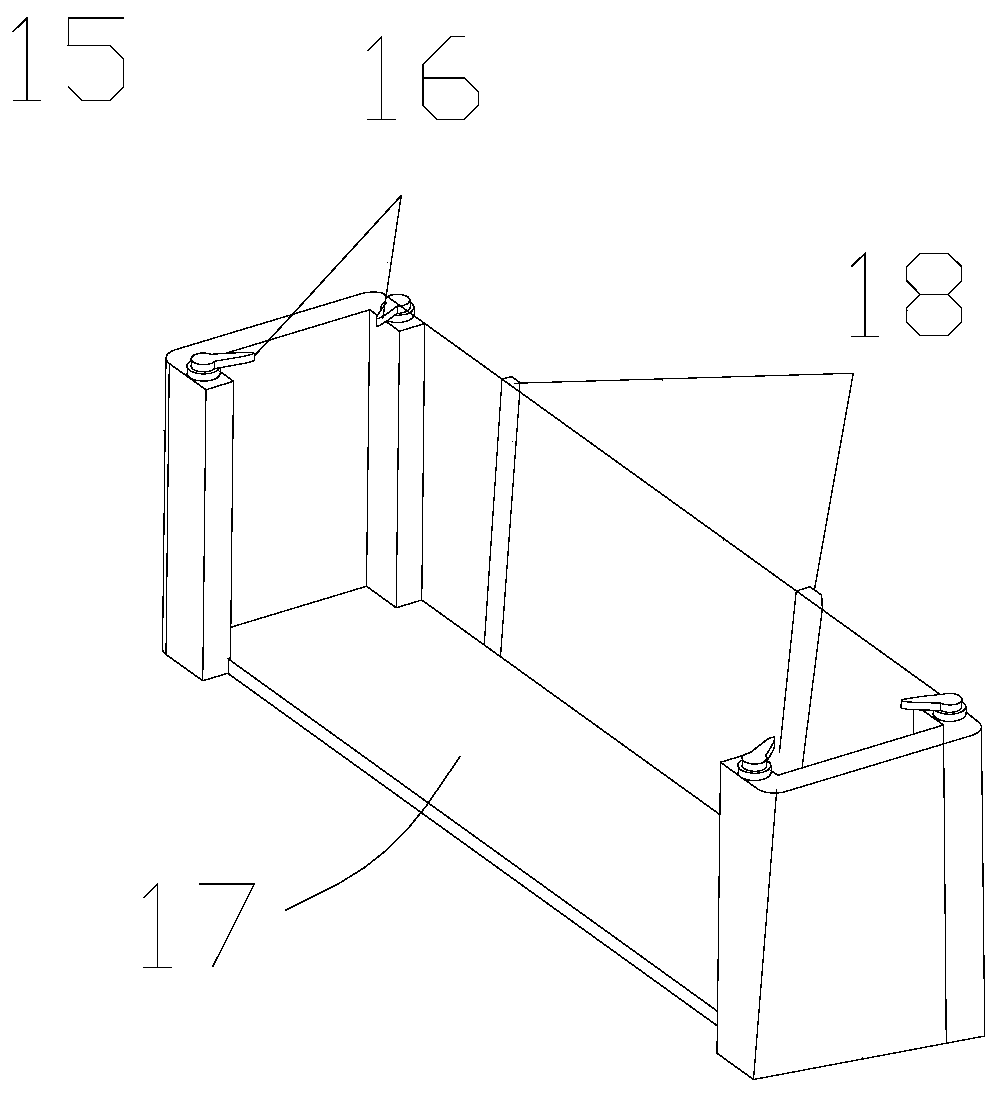

[0037] The invention provides a device for auxiliary battery soaking, such as Figure 1-7 As shown, the device includes a rotating unit 1, a heating unit 2 and a housing 3 with a chamber 31, the rotating unit 1 is rotatably mounted on the housing 3 and has a protruding part, the protruding part is set to be able to install and drive a plurality of batteries 4 filled with electrolyte to rotate, the heating unit 2 is installed on the housing 3 and is set to be able to control the cavity 31 The heat treatment is performed so that the battery 4 accommodated in the chamber 31 reaches a soaking temperature. Wherein, the casing 3 can be set in various reasonable forms, for example, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com