Low-liquor-ratio continuous dyeing device and dyeing method thereof

A technology of dyeing device and liquid ratio, which is applied in the direction of dyeing method, equipment configuration for processing textile materials, heating/cooling of fabrics, etc. It can solve the problems of wasting dye, low dyeing ratio, uneven dyeing of production line, etc., and achieve shrinkage control High efficiency, easy to control the depth of dyeing, and the effect of greatly increasing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

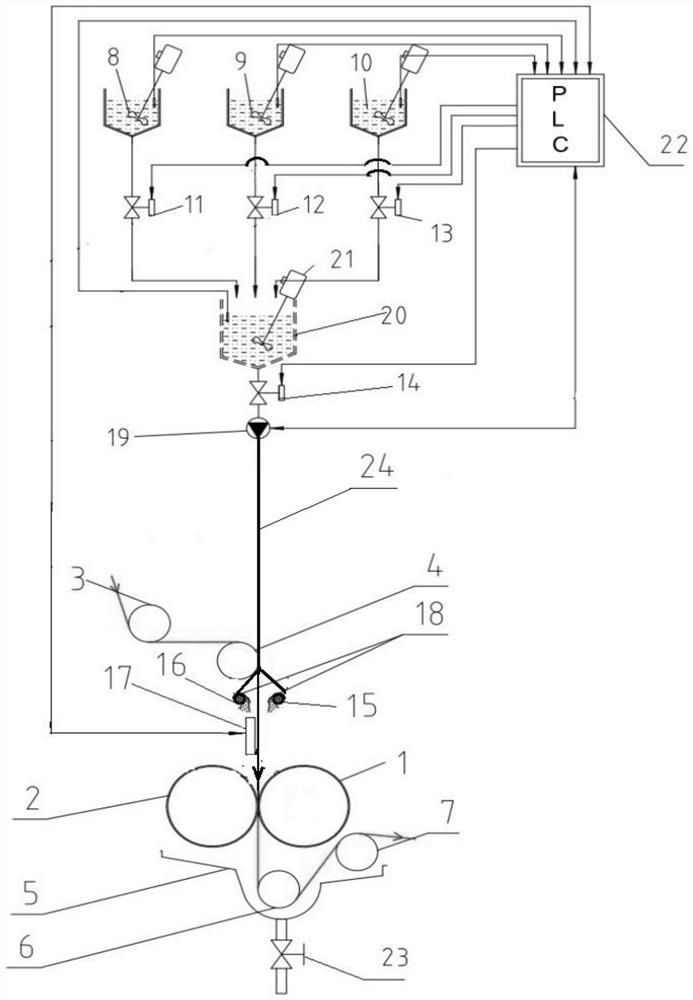

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] combine figure 1 , the low liquid ratio continuous dyeing device includes: rubber driving roller 1, rubber passive roller 2, cloth feeding guide roller 3, expansion roller 4, stainless steel bottom groove 5, bottom guide roller 6, cloth outlet guide roller 7, the first A working fluid bucket 8, a second working fluid bucket 9, a bucket 10, a first automatic valve 11, a second automatic valve 12, a bucket valve 13, a proportional valve 14, a first rehydration conveyor 15, a second rehydration conveyor 16, Liquid level control induction head 17, liquid replenishment pump 19, mixer 20, electric mixer 21, liquid outlet valve 23 and delivery pipe 24; the upper part of the port of mixer 20 is horizontally arranged with a first working fluid tank 8 and a second working fluid tank 9 in sequence And bucket 10, the first working fluid b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com