Formula of efficient silicon-boron system impregnant as well as preparation and application processes of efficient silicon-boron system impregnant

A technology of impregnating agent and silicon boron, which is applied in the field of impregnating agent for electrolytic aluminum anode carbon block, high-efficiency silicon boron system impregnating agent formula and its preparation and application process, which can solve the problem of unsatisfactory product purity, insufficient impregnation depth and long impregnation time to avoid inconsistent reaction rates, high dispersion stability, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a high-efficiency silicon-boron system impregnating agent, which is a solution prepared by borax, sodium silicate and water. In terms of mass fraction, the boron content in the solution is 2%, the silicon content is 2%, and the balance is water.

[0031] The impregnating agent in this embodiment is prepared and used immediately when the electrolytic aluminum anode is replaced, and the specific preparation and application method includes the following steps:

[0032] A. Weigh borax and sodium silicate according to the proportion of the impregnating agent components, first put the two into a stirring container, add water to dissolve, and mix evenly at a stirring speed of 80rpm;

[0033] B. Record the impregnating agent configured in the previous step and store it for future use;

[0034] C. Place the prebaked anode carbon block in the impregnation tank, and carry out vacuum treatment, so that the vacuum degree in the tank is 300pa;

[0035] D. I...

Embodiment 2

[0040] The difference between this example and Example 1 is that in the high-efficiency silicon-boron system impregnating agent in this example, the boron content is 2%, the silicon content is 4%, and the rest is water. The steps of the specific preparation and application methods are the same as those in the examples.

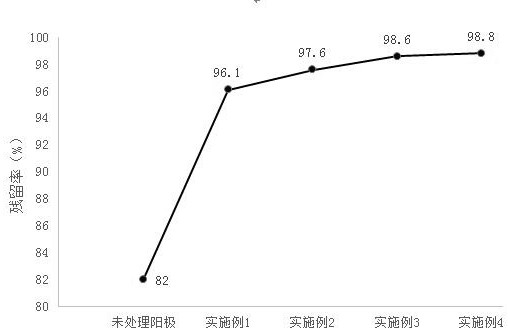

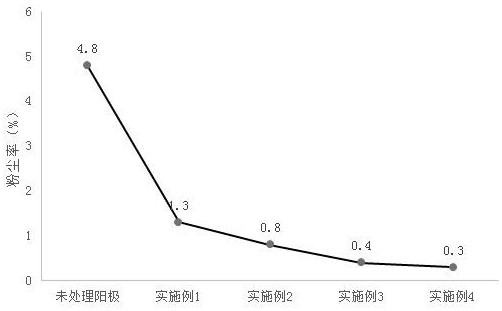

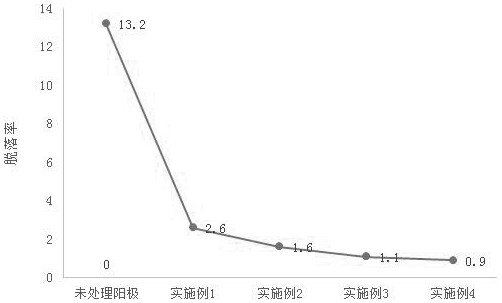

[0041] Air reactivity test was performed on the anode after step E in this embodiment, and the residual rate was 97.6%, the dust rate was 0.8%, and the loss rate was 1.6%.

Embodiment 3

[0043] The difference between this example and Example 1 is that in the high-efficiency silicon-boron system impregnating agent in this example, the boron content is 2%, the silicon content is 4%, and the rest is water. The steps of the specific preparation and application methods are the same as those in the examples.

[0044] Air reactivity test was performed on the anode after step E in this embodiment, and the residual rate was 98.5%, the dust rate was 0.4%, and the loss rate was 1.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com