Fractional-slot high-temperature superconducting generator stator

A generator stator, high-temperature superconducting technology, applied in the usage of superconductor elements, electrical components, electromechanical devices, etc., can solve the problems of increased AC loss, AC loss of superconducting coils, etc., to improve operating efficiency, increase power density, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not constitute a limitation to the present invention.

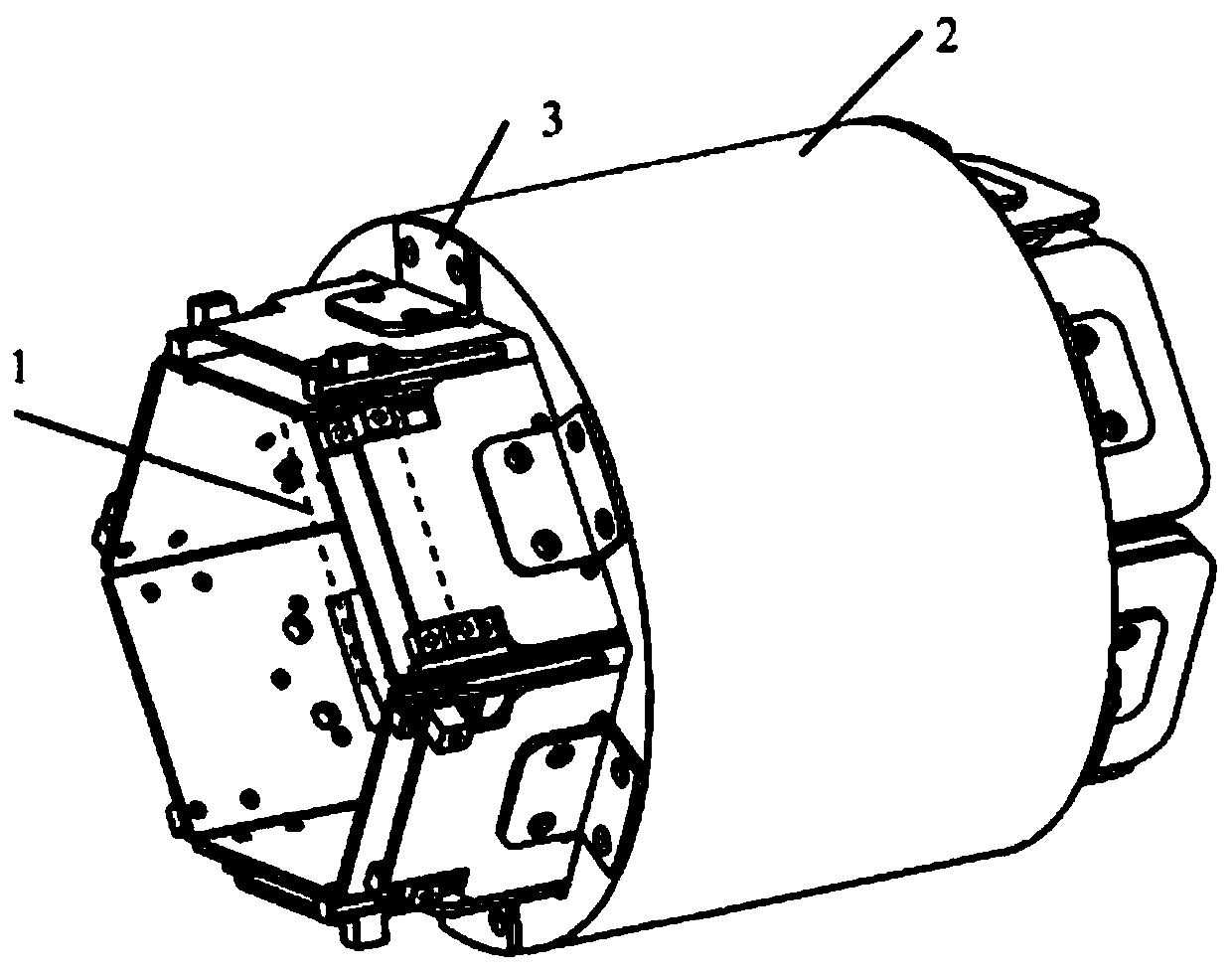

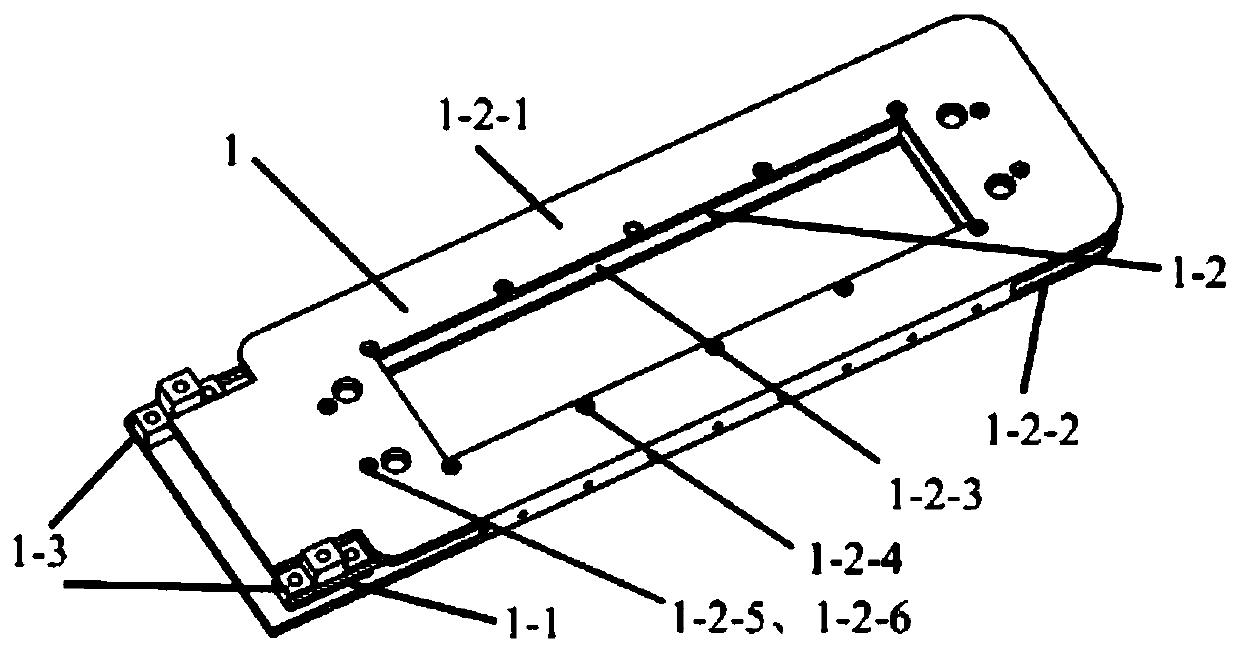

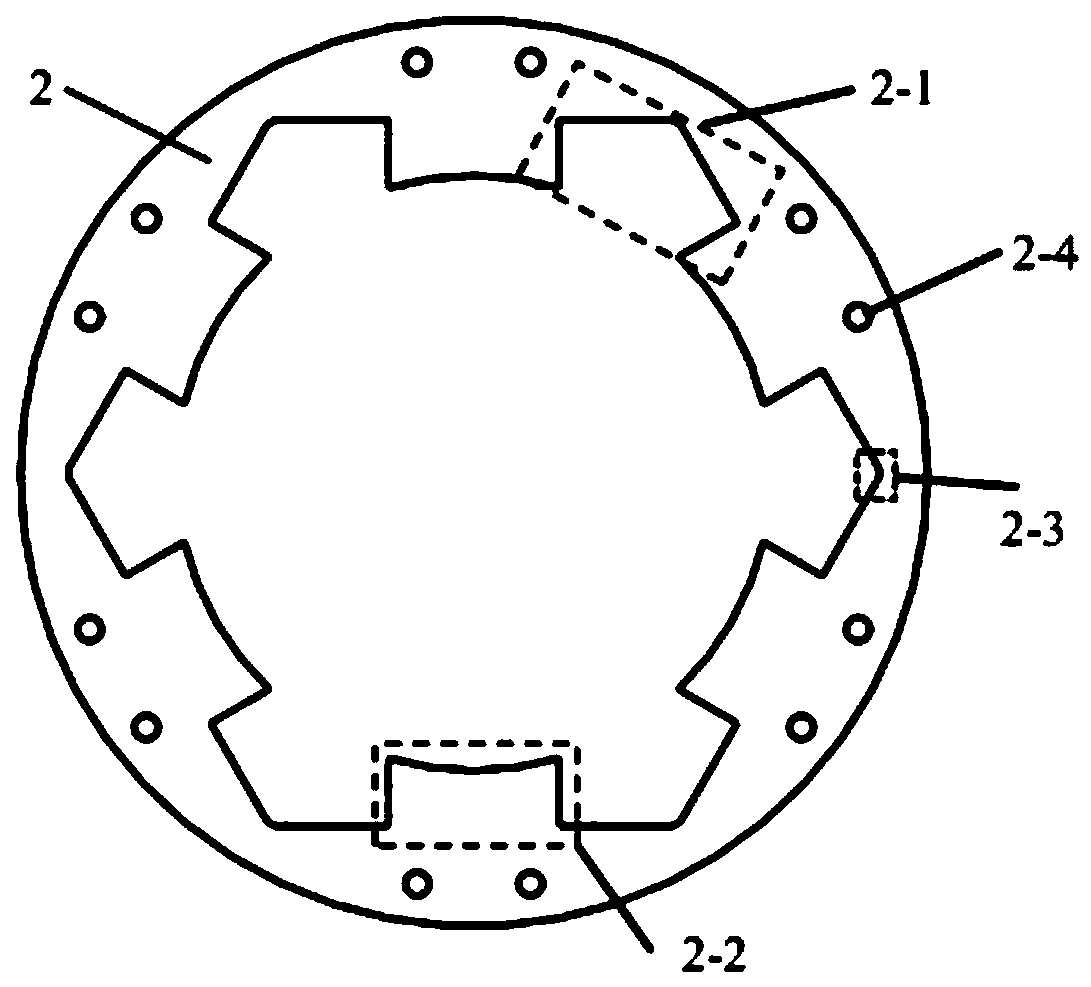

[0024] like figure 1 As shown, a high temperature superconducting generator stator with fractional slots has a superconducting motor stator core device. The stator core 2 is provided with evenly distributed polygonal opening slots and parallel tooth structures, the superconducting wire coil 1 is installed in the polygonal opening slot, and the superconducting wire coil 1 and the stator core 2 are fixedly connected through the baffle plate 3 . The design of the polygonal notch is conducive to the installation and disassembly of the entire reel, and the linearization or rounding of the sharp corners can weaken the magnetic concentration effect of the iron core, reduce the surface magnetic field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com