Method for treating a salt solution using multistage separation processes, and treatment system for this purpose

A technology for processing systems and salt solutions, applied in separation methods, wet separation, solid separation, etc., can solve the problems of high cost, high kainite content, high equipment cost and complexity, and achieve burden reduction and obvious technology , reduce the effect of using modulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

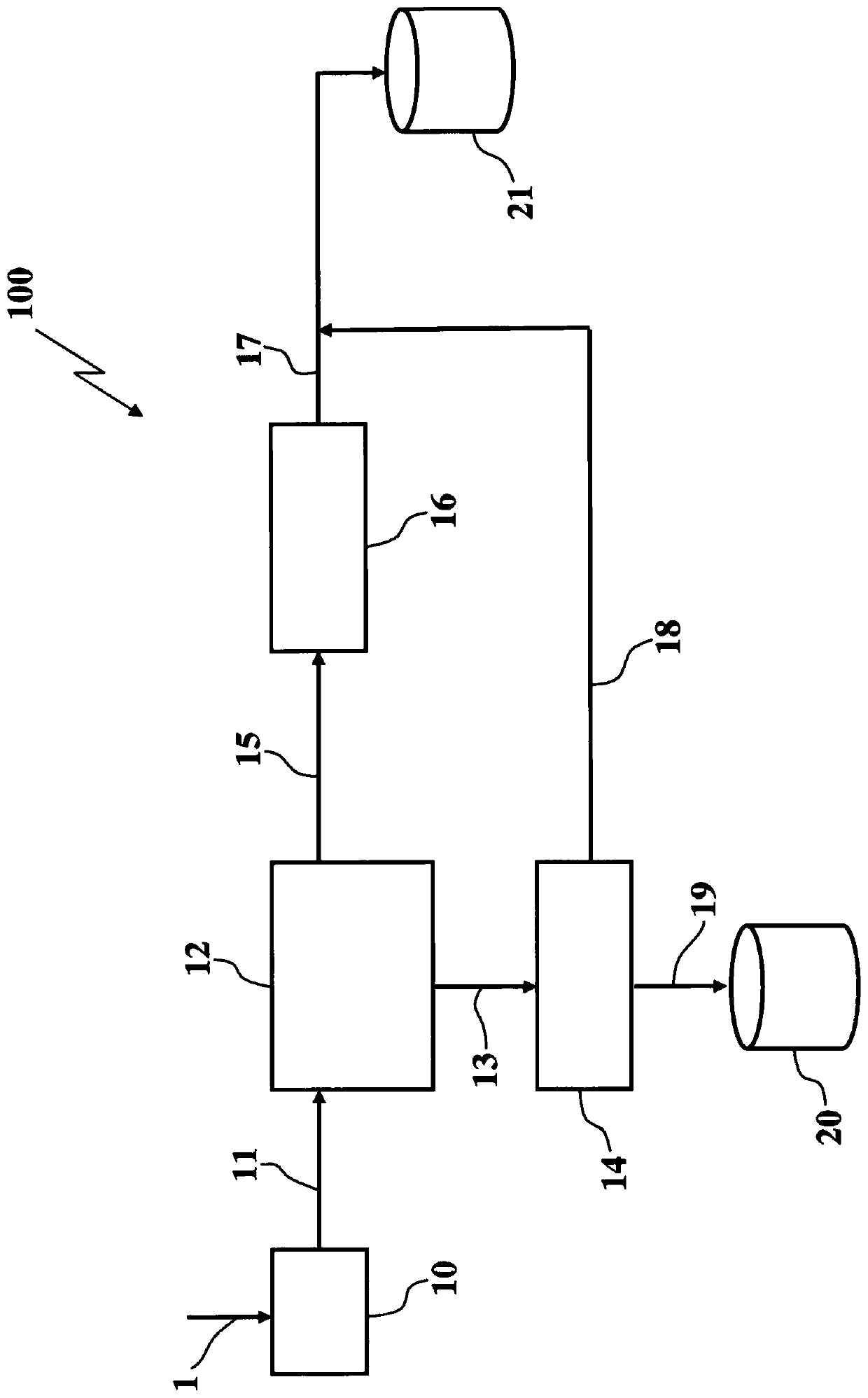

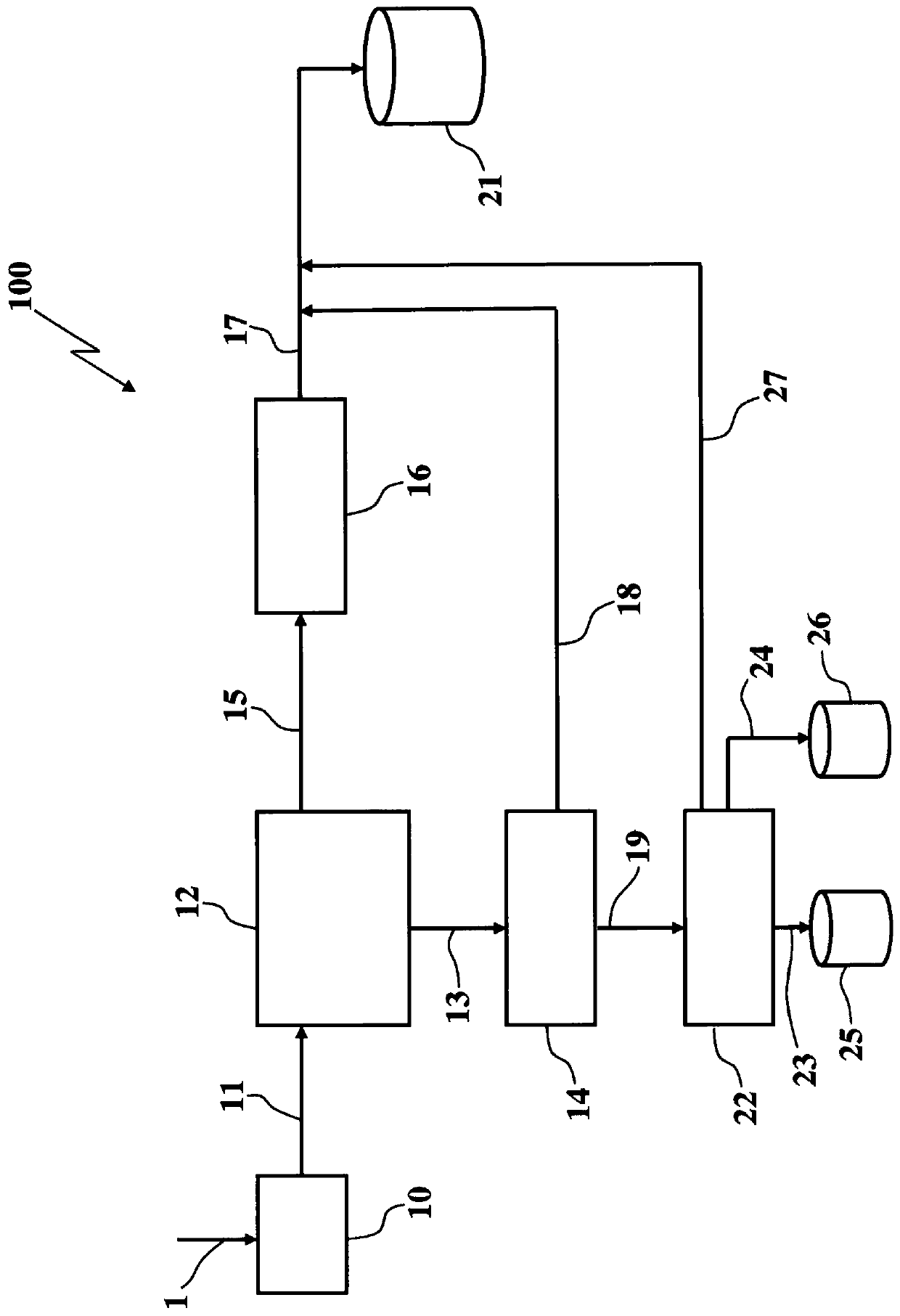

[0029] figure 1 and figure 2 A schematic diagram of a treatment system 100 is shown, wherein the treatment system 100 comprises an evaporation plant 10, which is supplied with a brine 1 formed in an upstream operation, and from which can be obtained materials including langbeinite, halite and A crystalline suspension 11 of the potassium salt, and then at least partially removing kainite from the crystalline suspension 11.

[0030] In this case, the crystalline suspension 11 is first supplied to a pre-classification device 12 in which the langbeinite was removed, thereby obtaining langbeinite-reduced fraction 13. Subsequently, the langbeinite-reduced fraction 13 is transferred to a flotation unit 14 in which the remaining proportion of langbeinite is removed, in particular mainly removed, from the langbeinite-reduced fraction 13 .

[0031] The pre-classification device 12 comprises, for example, a sorting screw, in which case langbeinite is removed from the crystalline susp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap