Leaking stoppage device

A technology of plugging and leaking rods, which is applied in the field of plugging devices and can solve problems such as the inability to immediately cut off the communication between the mold and the molten metal in the crucible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

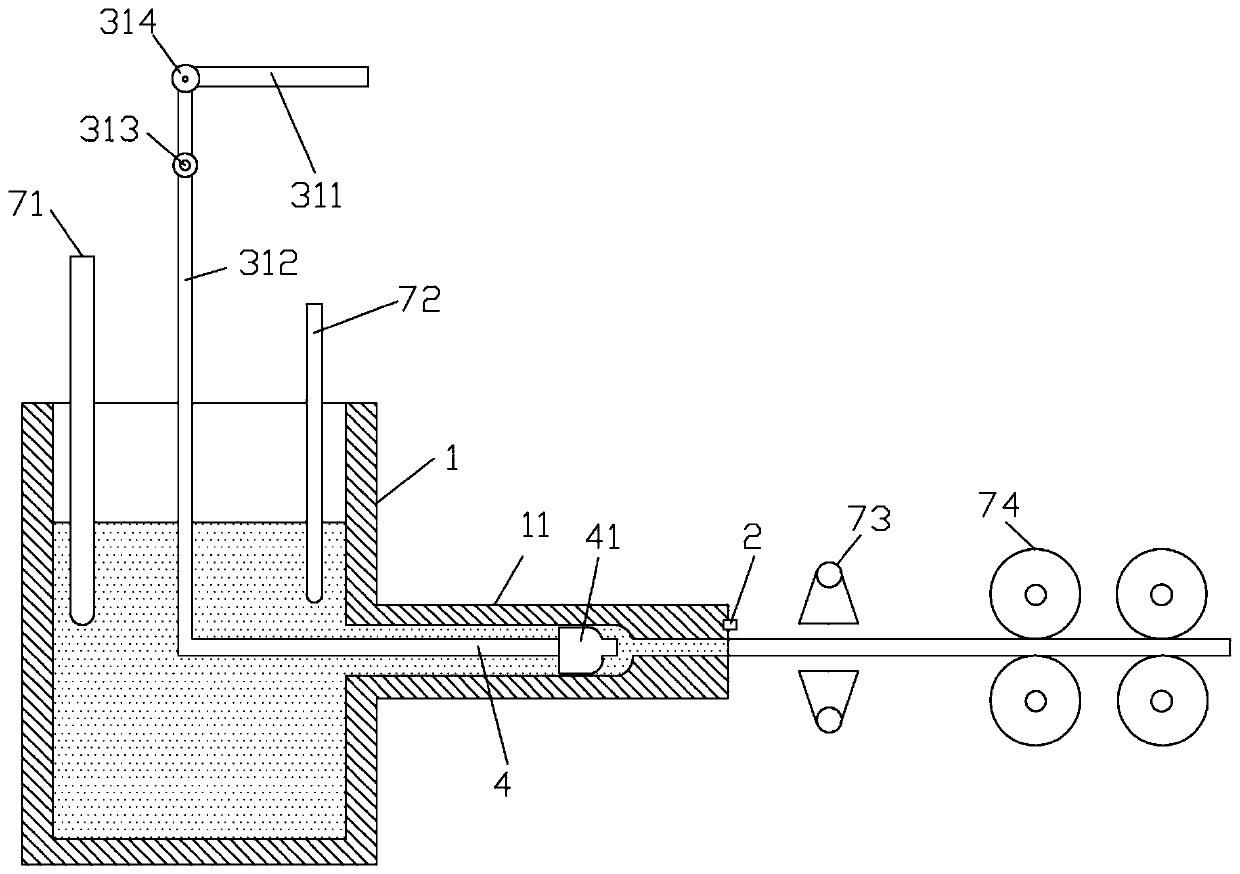

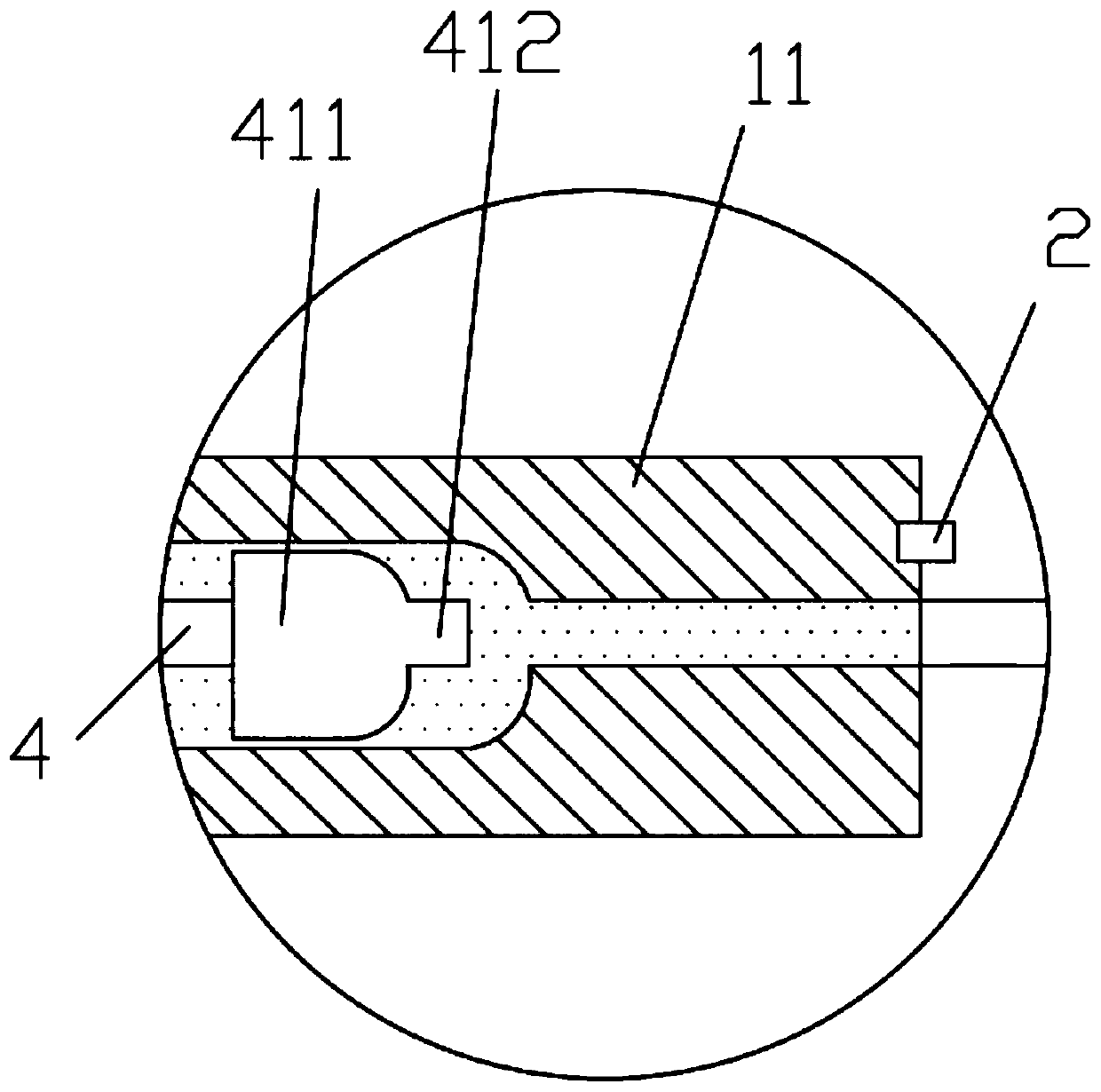

[0031] Please refer to figure 1 , the application provides a kind of embodiment, and this embodiment comprises box body 1, temperature sensor 2, controller, driver 3 and plugging rod 4; Box body 1 is provided with drain pipe 11, and the liquid inlet of drain pipe 11 The mouth is located on the side wall of the box body 1, and the plugging rod 4 is arranged inside the drain pipe 11, and the leak plugging rod 4 is provided with a plug 41 matching the liquid outlet of the drain pipe 11; the temperature sensor 2 is arranged on the The periphery of the liquid outlet of the discharge pipe 11; the temperature sensor 2 is connected with the controller, and the controller is connected with the driver 3; the driver 3 is provided with a driving rod 31, and the driving rod 31 is connected with the plugging rod 4; When the temperature value is greater than the set value of the controller, the controller controls the driver 3 to drive the driving rod 31 to drive the plugging rod 4, so that ...

Embodiment 2

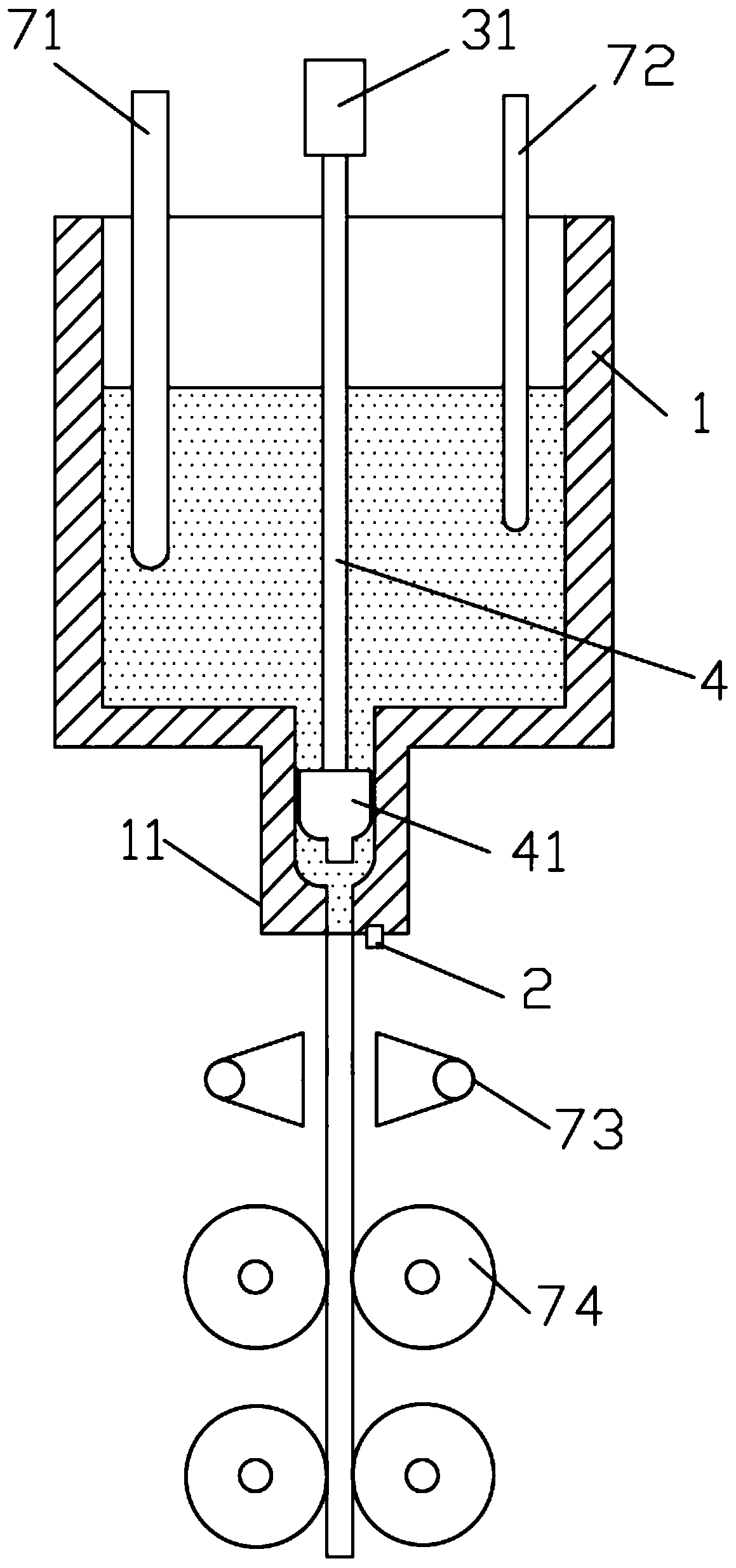

[0046] Please refer to image 3 , the application also provides another embodiment, the present embodiment includes a casing 1, a temperature sensor 2, a controller, a driver 3 and a plugging rod 4; the casing 1 is provided with a drain pipe 11, the drain pipe 11 The liquid inlet is located on the bottom wall of the box body 1, and the plugging rod 4 is arranged inside the drain pipe 11, and the leak plugging rod 4 is provided with a plug 41 matching the liquid outlet of the drain pipe 11; the temperature sensor 2 Set on the periphery of the liquid outlet of the discharge pipe 11; the temperature sensor 2 is connected to the controller, and the controller is connected to the driver 3; the driver 3 is provided with a driving rod 31, and the driving rod 31 is connected to the plugging rod 4; when the temperature sensor 2 When the detected temperature value is greater than the preset temperature of the controller, the controller controls the driver 3 to drive the driving rod 31 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com