Numerical control servo machining system for gas separation pipes of combustor

A processing system and air distribution pipe technology, which is applied in the field of mechanical processing, can solve the problems of low processing efficiency of air distribution pipes, achieve the effects of improving processing production efficiency and product quality, improving hole distance and tapping precision, and reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

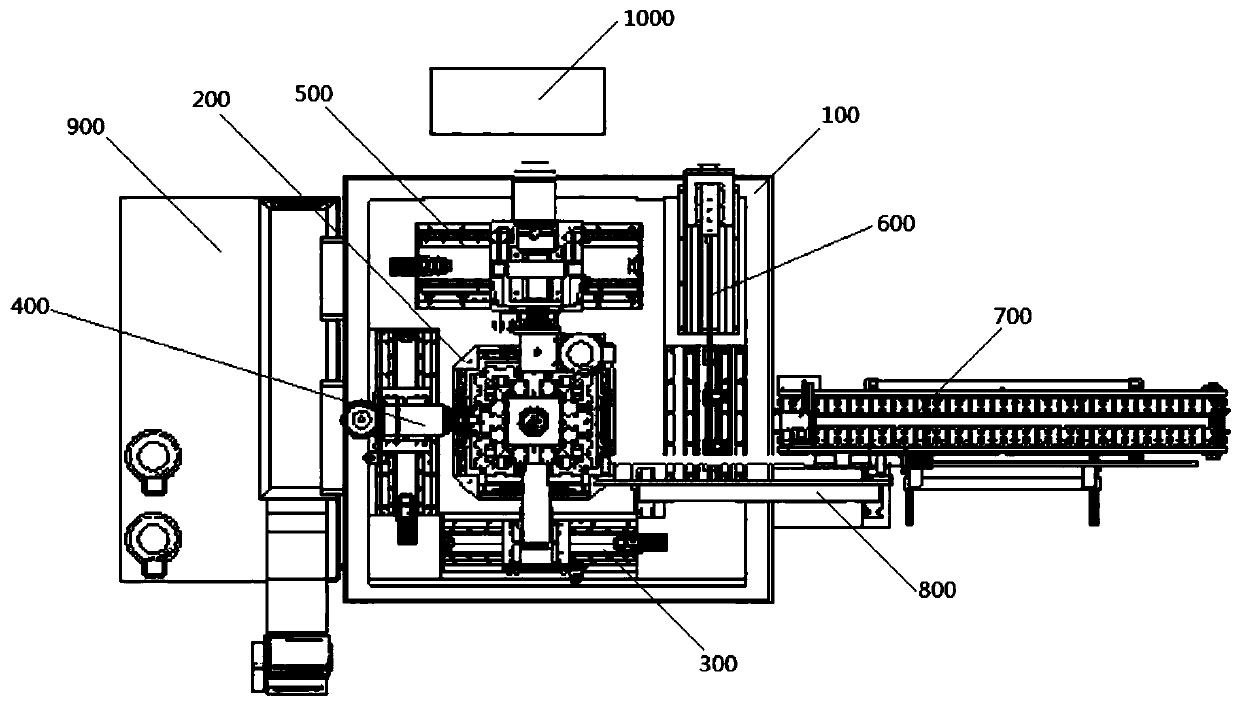

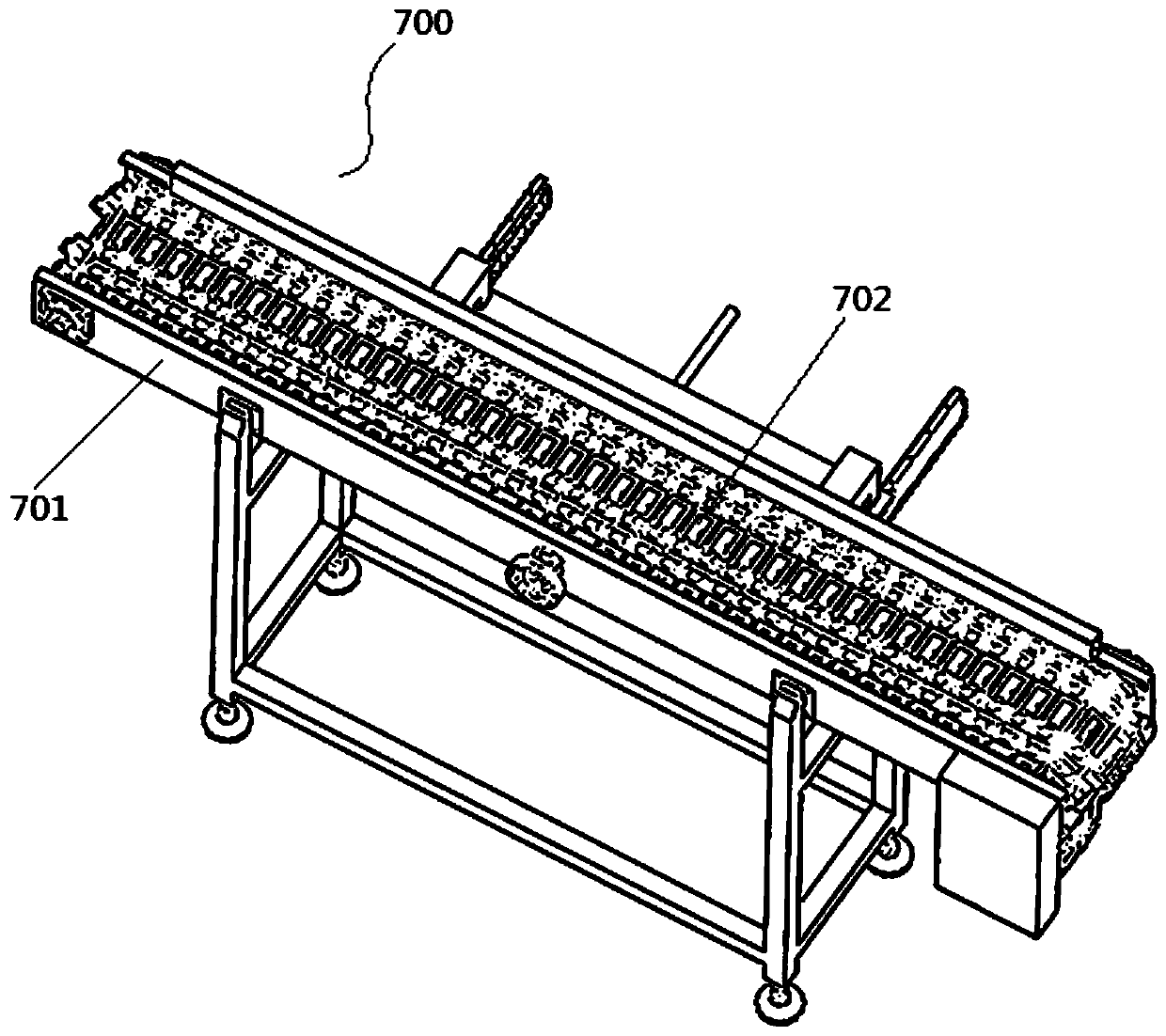

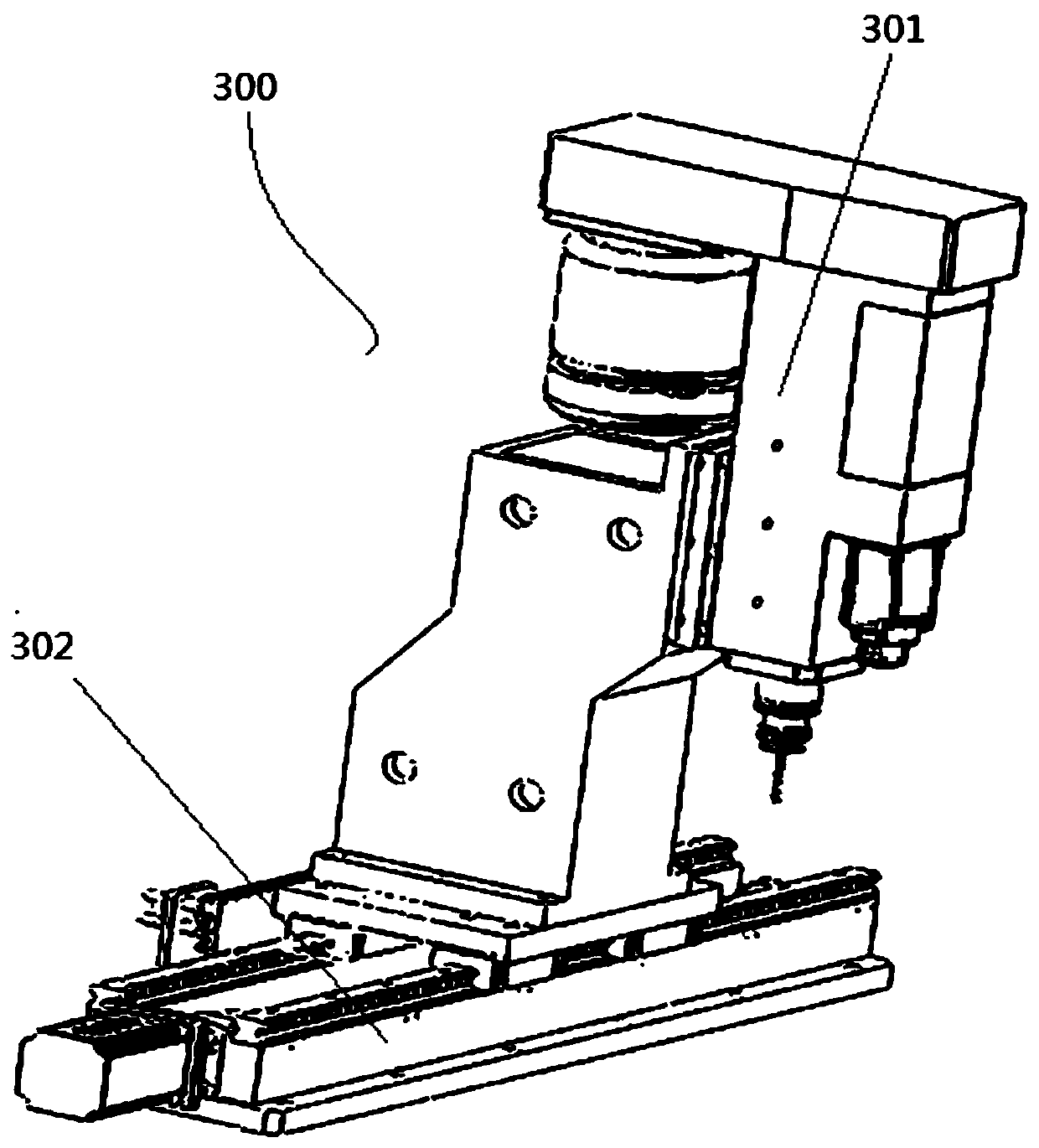

[0032] Such as figure 1 , a kind of numerical control servo processing system of burner gas distribution pipe, comprises base 100, the turntable 200 that is rotated on this base 100, and the drilling mechanism 300 that is arranged around turntable 200, tapping mechanism 400, milling plane mechanism 500 and The deburring mechanism 600, the processing system also includes a chain plate line mechanism 700 for conveying workpieces, and a manipulator mechanism 800 for grabbing workpieces, and a clamp for fixing and clamping workpieces is provided on the turntable 200, and the clamps are hydraulic clamps , that is, the current general-purpose hydraulic clamp, which is fixedly installed on the turntable and used to fix and clamp the workpiece. Both the base 100 and the turntable 200 are square, the drilling mechanism 300, the tapping mechanism 400, the plane milling mechanism 500 and the deburring mechanism 600 are installed on the base 100 at an interval of 90°, the chain plate line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com