Sand blasting process applied to environment-friendly box variable shell

An environmental protection box and sandblasting technology, which is applied in the direction of manufacturing tools, metal processing equipment, abrasive feeding devices, etc., can solve the problems of large unevenness, etc., and achieve the effect of smooth construction surface, convenient use, and reduced coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

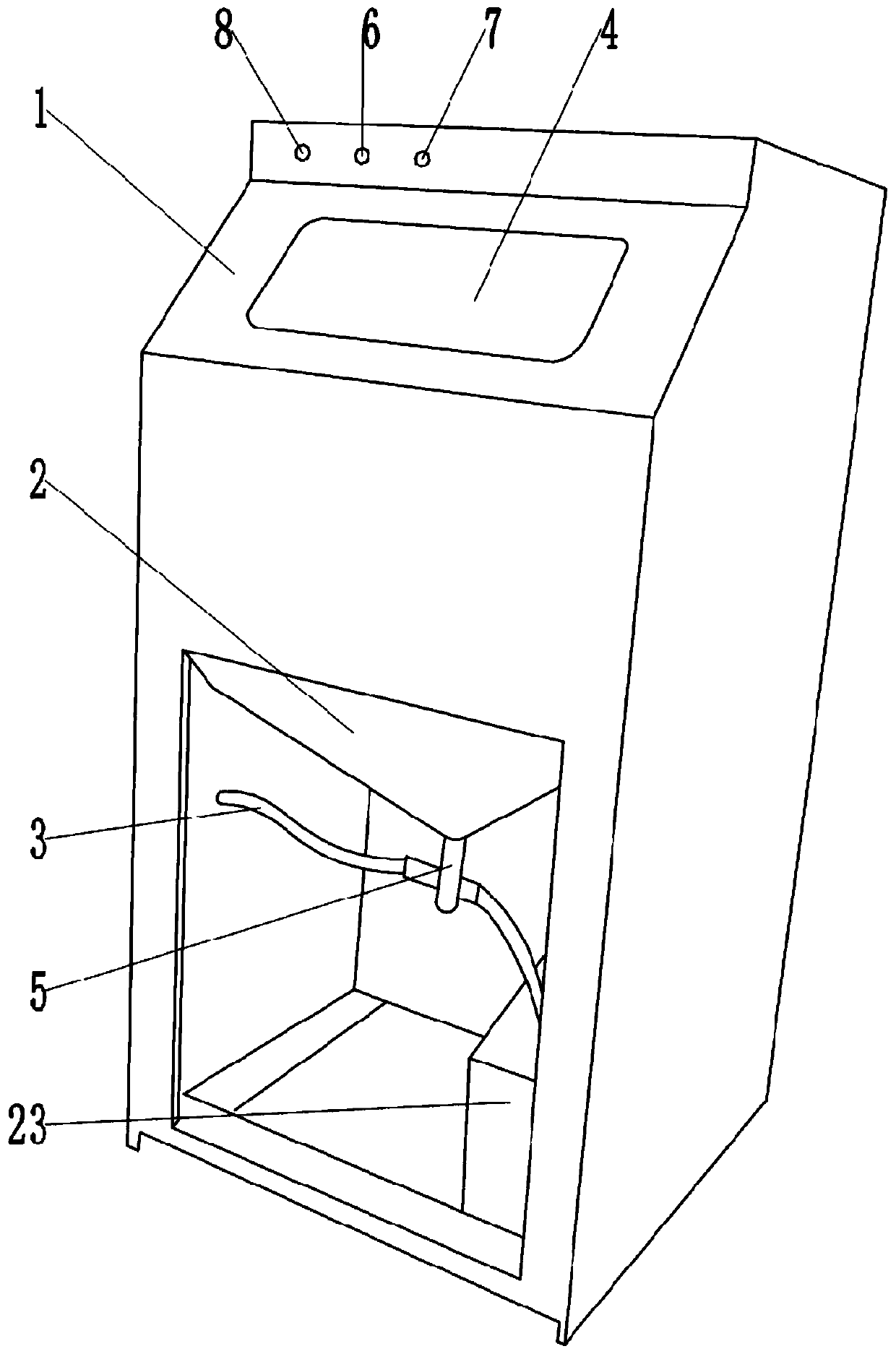

Image

Examples

Embodiment 1

[0041] A sandblasting process applied to the shell of an environmental protection box mainly includes the following steps:

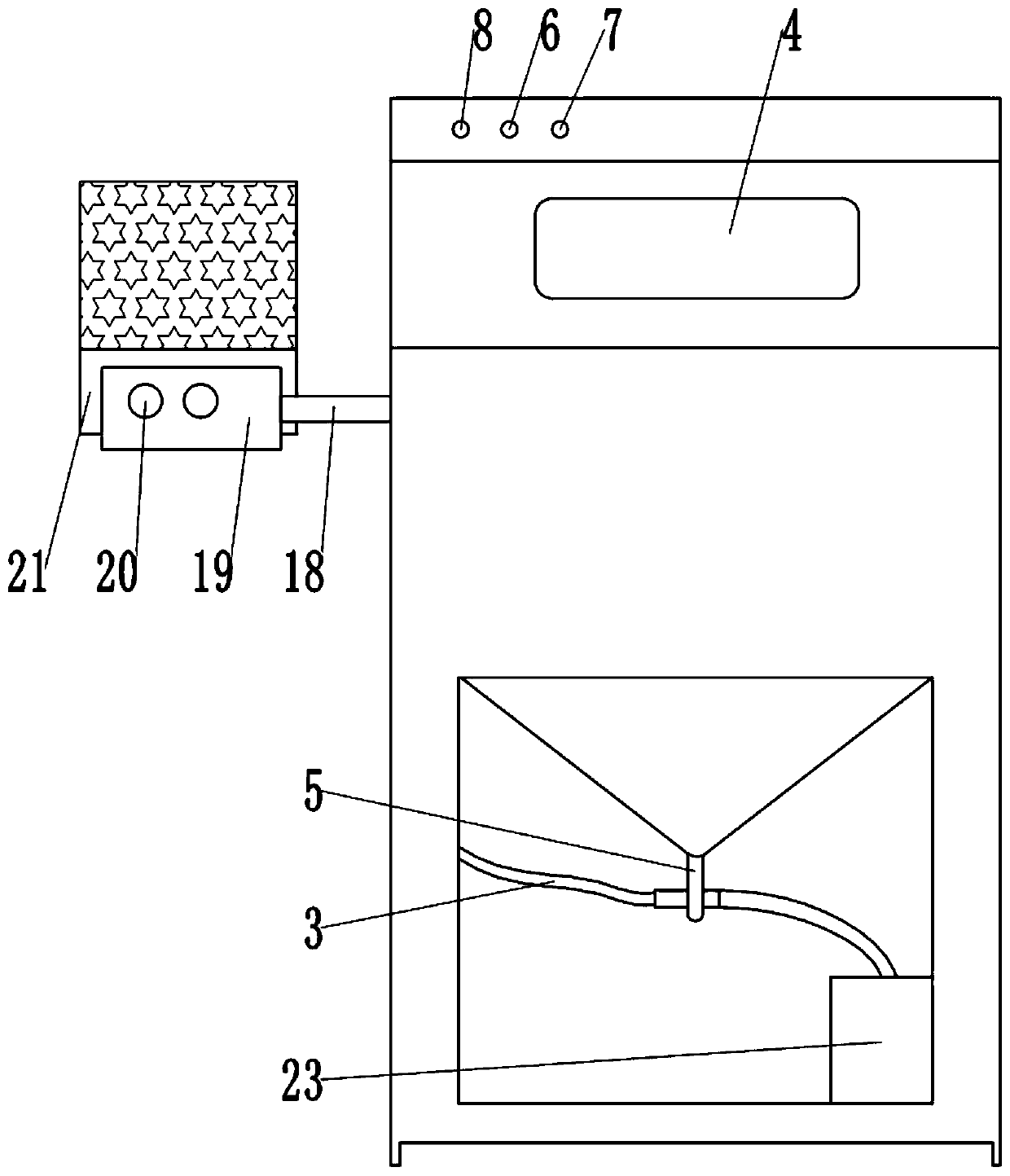

[0042] Step A, making the template 21: Hollow out the middle part of the template 21 by drilling or hollowing out, so that the hollowed out part forms the required pattern, so as to obtain the required template 21, such as figure 2 As shown, here take the form of a five-pointed star hollowed out on the template 21 as an example;

[0043] Step B, clean the base wall: clean the dust on the base wall, and repair the holes on the base wall; when there is a release agent on the base wall, use a wire brush to clean the release agent;

[0044] Step C, wetting the base wall surface: After the base wall surface is cleaned, spray water on the base wall surface to fully wet the base wall surface. The wetting depth is about 2-4mm. Here, 2.8mm is taken as an example for illustration;

[0045]Step D, sandblasting construction: because the prepared sandblasting mater...

Embodiment 2

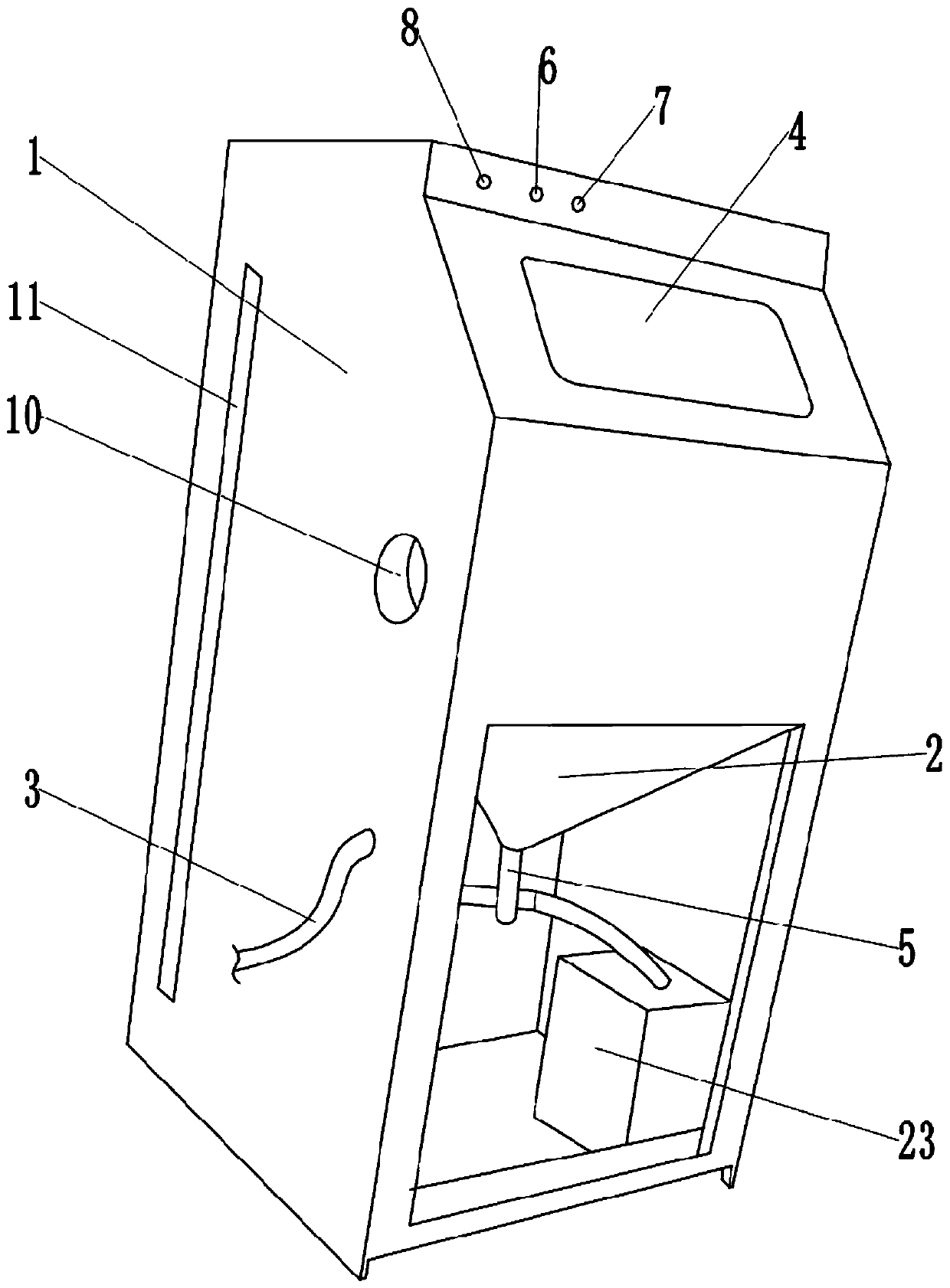

[0057] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the bottom of the stirring chamber is an inclined slope with a high left and a low right, and a feeding port 9 is provided on the right side of the bottom of the stirring chamber, and the feeding port 9 is located on the top of the sand storage bucket 2. side. The stirring chamber is connected with the stirring shaft 12 through the bearing rotation, and the stirring shaft 12 is inclined to the left and right, and the inclination angle of the stirring shaft 12 is the same as that of the bottom of the stirring chamber; the surrounding wall of the stirring shaft 12 is welded and fixed with multiple The stirring rod 17, the end of the stirring rod 17 away from the stirring shaft 12 can be in contact with the bottom of the stirring chamber, so that the stirring is more thorough. The insides of the stirring shaft 12 and the stirring rod 17 are hollow, and the stirring shaft 12 and the...

Embodiment 3

[0061] The difference between the present embodiment and the first embodiment is that there are multiple templates 21, and the same patterns are hollowed out on the multiple templates 21, and three templates 21 are used as examples for illustration. This scheme is mainly used in the situation where multiple identical patterns are formed by spraying on the base wall. When a single formwork 21 is worn out after repeated use or cannot reach the cleanliness required for construction, the operator can directly replace a formwork 21 to continue construction. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com