Mechanical claw for machinery manufacturing

A technology of mechanical manufacturing and mechanical claws, which is applied in the field of mechanical manufacturing auxiliary devices, can solve problems such as high wear, increased user costs, and damage to surrounding objects, and achieve the effects of reduced production costs, good protection effects, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

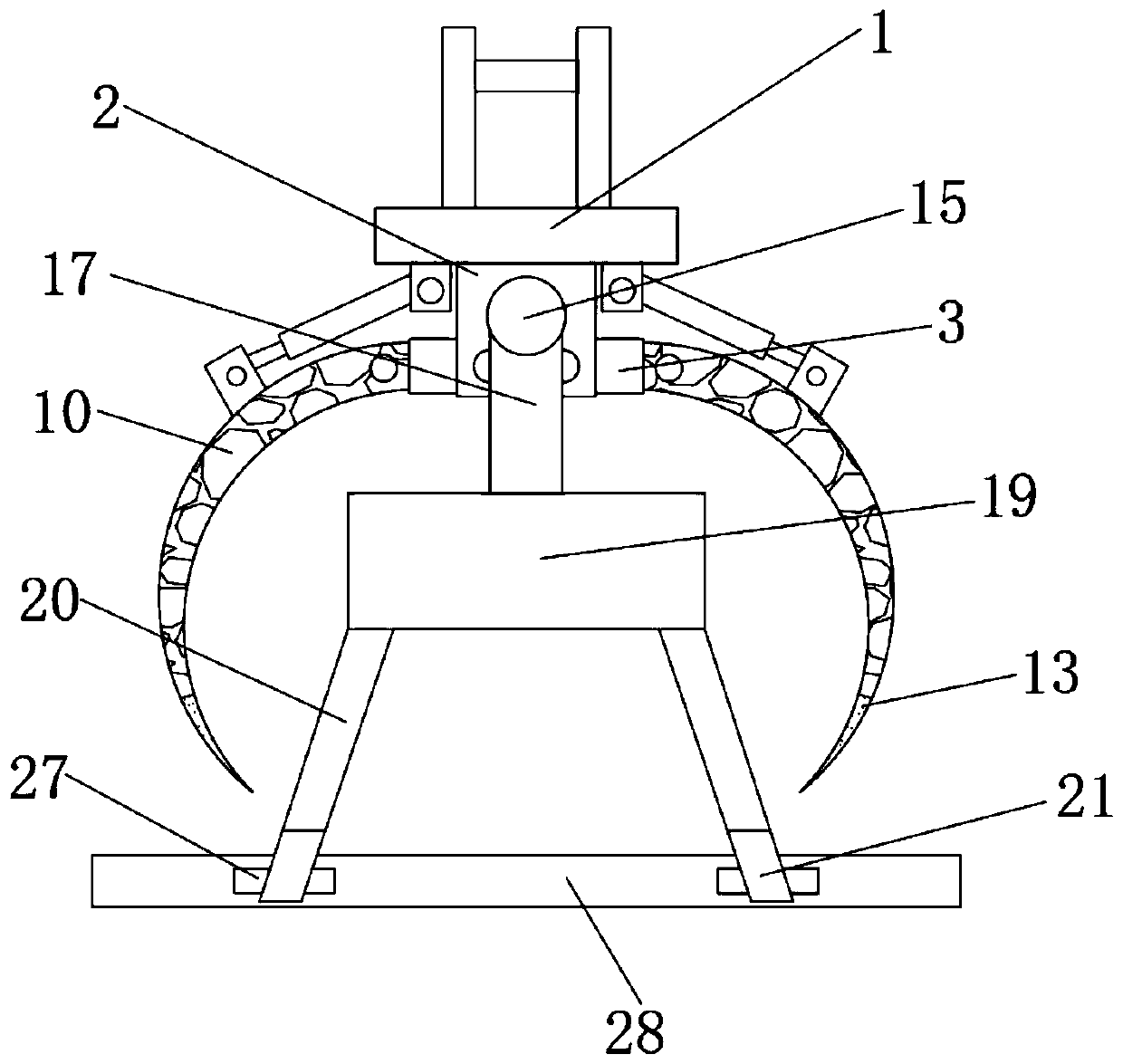

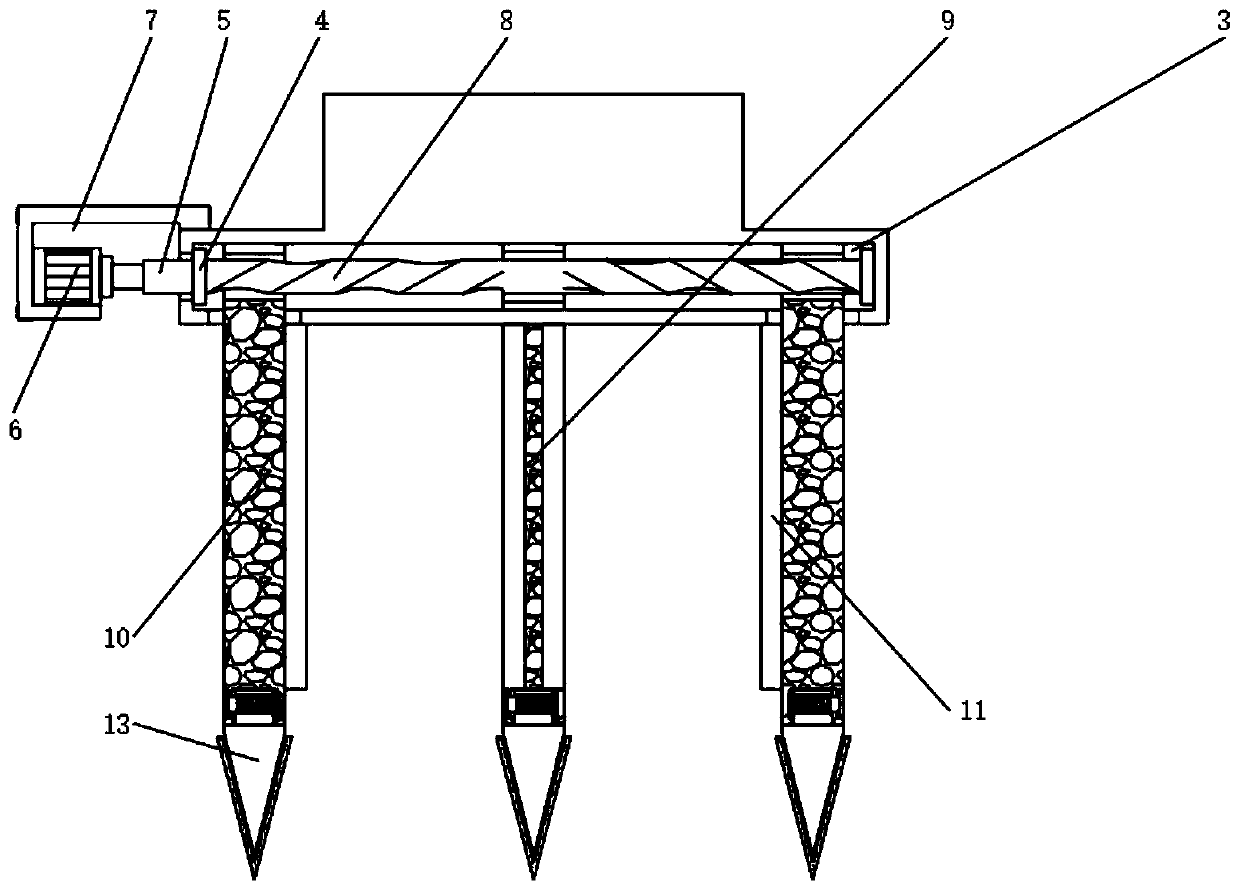

[0030] Depend on Figure 1-6 Provided, the present invention includes an assembly block 1, the bottom of the assembly block 1 is fixed with a retaining block 2, the side of the retaining block 2 is equipped with a positioning block 3, and the side of the cavity of the positioning block 3 is equipped with a bearing 4, through which the bearing 4 setting, so that the rotation of the adjustment rod 8 is more stable, the side of the bearing 4 is equipped with a transmission rod 5, through the setting of the transmission rod 5, the adjustment motor 6 can perform stable power transmission, and the transmission rod 5 extends to one end outside the positioning block 3 An adjusting motor 6 is installed, and the side of the adjusting motor 6 is equipped with a placement frame 7, and the other side of the bearing 4 is installed with an adjusting rod 8, and the middle part of the adjusting rod 8 is installed with a central claw 9, and one end of the adjusting rod 8 is threadedly connected ...

Embodiment 2

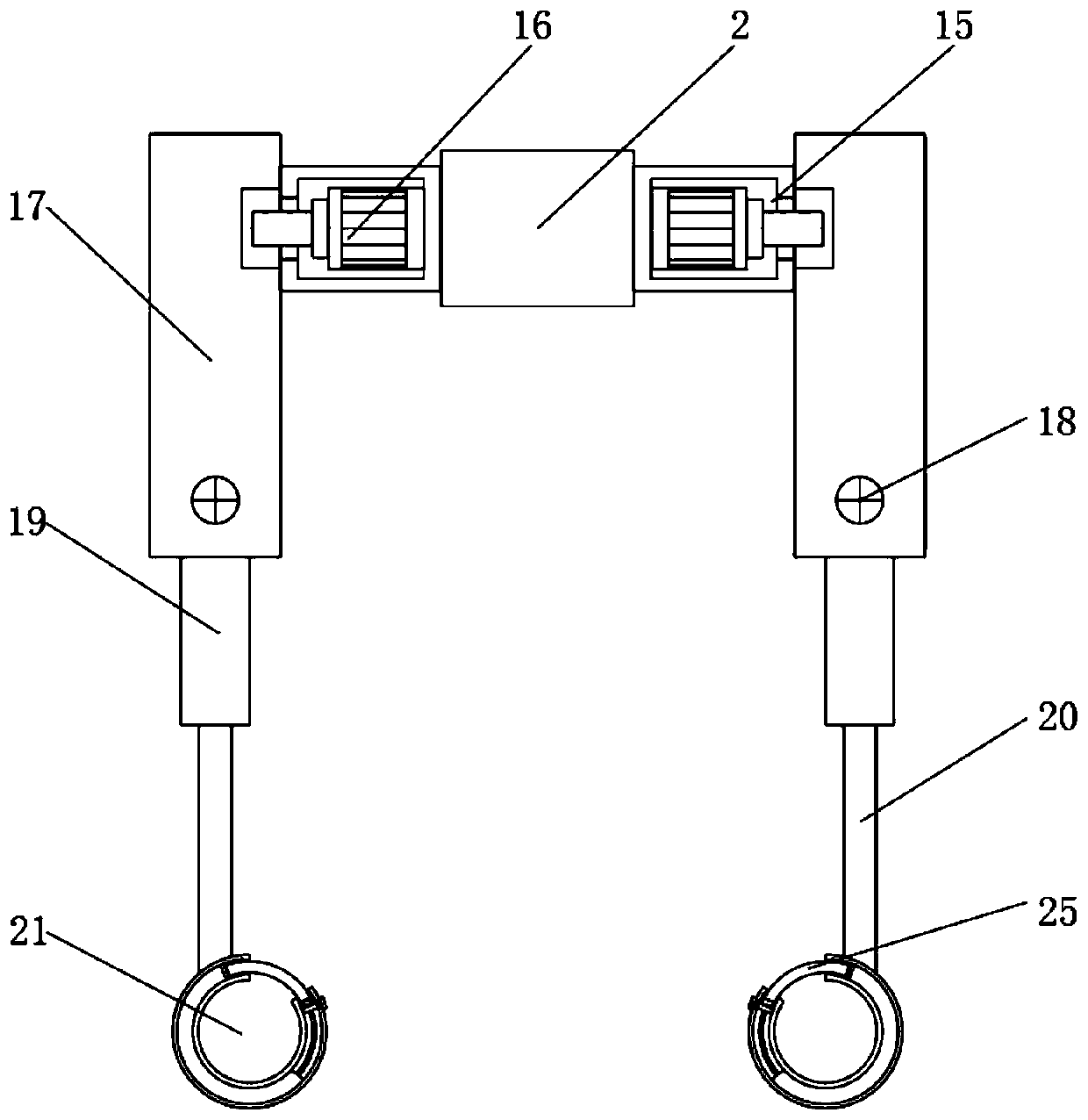

[0032] On the basis of Embodiment 1, the left and right sides of the surface of the retaining block 2 are matched with the sides of the positioning block 3, and the front and rear sides of the surface of the retaining block 2 are matched with the sides of the protective box 15, through the setting of the retaining block 2 , so that both the positioning block 3 and the protective box 15 are effectively installed, thereby using the positioning block 3 and the protective box 15 to realize different functions.

Embodiment 3

[0034] On the basis of Embodiment 1, parallel grooves are provided on the side of the branch claw 10, and the parallel groove on the branch claw 10 is on the same horizontal line as the top of the first screw 12. Through the setting of the branch claw 10, it can be used The parallel groove prevents the first screw 12 from protruding from the surface of the branch claw 10 , which reduces the appearance of the branch claw 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com