Brake lamp sensor

A sensor and brake light technology, applied in optical signals, signaling devices, transportation and packaging, etc., can solve problems such as affecting driving safety, power failure, loss of two-way signals BLS and BTS, etc., to avoid complete loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

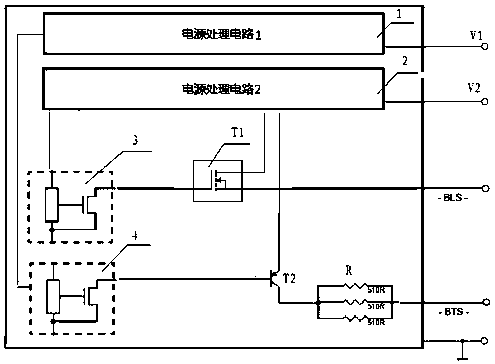

[0014] figure 1 The brake light sensor shown includes a power processing circuit, and there are two power processing circuits, one is the first power processing circuit 1, and the other is the second power processing circuit 2, the first power processing circuit 1 is the first Hall The element 3 provides working power, the second power processing circuit 2 provides working power for the second Hall element 4, the output terminal of the first Hall element 3 outputs a signal through the first switch tube T1, and the output of the second Hall element 4 The terminal outputs a signal through the second switch tube T2; the first switch tube T1 gets power from the first power processing circuit 1, and the second switch tube T2 gets power from the second power processing circuit 2. The output end of the second switch tube outputs a signal through the output res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com