A machining coolant filter device

A filtration device and machining technology, applied in filtration separation, filtration treatment, fixed filter element filter, etc., can solve the problems of low filtration efficiency, clogging of the filter screen, damage to the blades of the lift pump, etc. Inexpensive, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

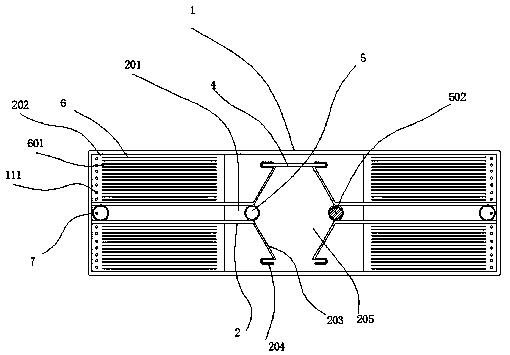

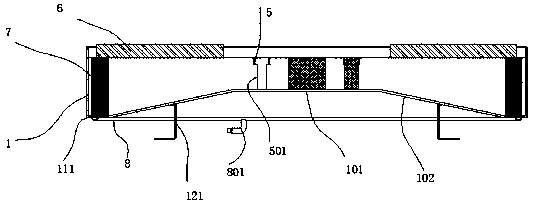

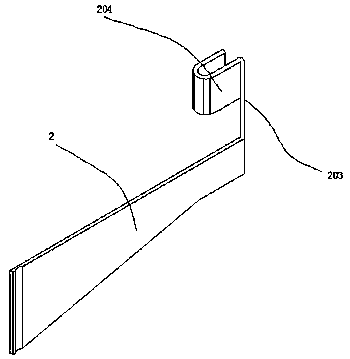

[0040] refer to figure 1 , figure 2 , image 3 with Figure 4 The shown machining coolant filtering device includes a separation tank 1, a platform surface 101 for diversion is provided at the bottom of the separation tank 1, and flow guides are formed on both sides of the platform surface 101. surface 102, the end of the diversion surface 102 away from the platform surface 101 is inclined downward, and four partitions 2 are symmetrically arranged in the front and rear inside the separation tank 1, and the partitions 2 are formed between the front and rear partitions. A channel 201 for separating non-magnetic chips, the side of the partition 2 away from the channel 201 forms a chamber 202 for separating magnetic chips, and the side of the partition 2 away from the center of the separation tank 1 One end is welded to the wall of the separation tank 1 to form a seal, and the end of the partition plate 2 away from the wall of the separation tank 1 is bent outward to form a di...

Embodiment 2

[0042] refer to Figure 5 with Image 6 As shown, the bottom of the adsorption plate 6 is movably installed between the separation tank 1, and a bead 131 is installed on the top of the separation tank 1, and the bead 131 is screwed to the separation tank 1, and the bottom of the bead 131 is A plurality of slots 141 for positioning the adsorption plate 6 are provided; more particles will be attached to the adsorption plate, if the adsorption plate is designed as a fixed structure, the particles on the adsorption plate need to be scraped when cleaning. However, the scraped particles will be re-adsorbed to the adsorption plate, resulting in ineffective cleaning. Therefore, we have designed the adsorption plate to be movable and fixed by pressing strips. When the adsorption plate needs to be cleaned, it can be removed. Pressing strips to remove the restriction on the adsorption plate. At this time, the adsorption plate can be taken out and cleaned, and then put back after cleanin...

Embodiment 3

[0044] refer to Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, a separation cylinder 9 is screwed at the inner bottom position of the intermediate cavity 205, and the filter hole diameter of the separation cylinder 9 is 0.5 mm ~ 1.2 mm, between the front and rear two closed plates 4 A cage 10 is welded, and the central position of the cage 10 is processed to form an annular body 11 assembled on the periphery of the separation cylinder 9, and a first cage 12 is welded between the two closing rods 502, The middle position of the first cage 12 is processed to form a first annular body 13 assembled on the periphery of the separation cylinder 9; the above-mentioned structure is mainly for the convenience of operation. First, the design of the separation cylinder is for cooling liquid Coarse filtration, the coarsely filtered particles can be quickly cleaned, reducing the filtration pressure on the adsorption plate and filter cartridge, the design of the cage can oper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com