Constant-temperature double-layer shaking pot for vegetable oil water substitution method production and water substitution method process method

A process method, the technology of water substitution method, is applied in the field of constant temperature double-layer swaying pot for vegetable oil water substitution method and water substitution method technology field, which can solve the problems of low oil yield, achieve high oil yield and save processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

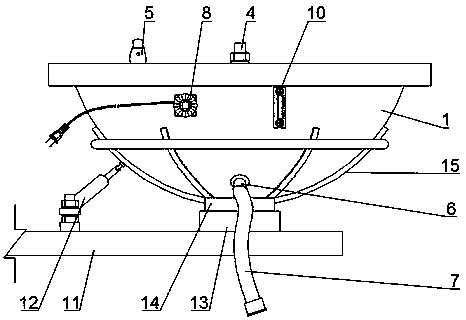

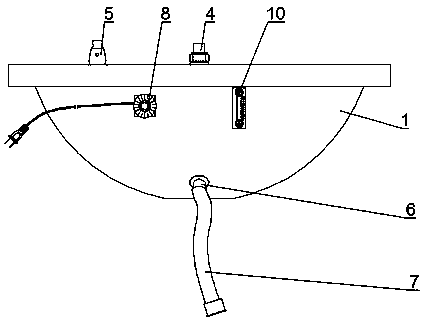

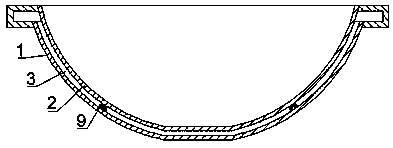

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The existing vegetable oil-water processing method is to inject the sauce embryos ground out of the stone mill into the shaking pot, then add hot water according to a certain proportion, and mix the sauce embryos and hot water by rotating the rake and the oil pot, etc., because the sauce The vegetable oil in the embryo is insoluble in water, and the specific gravity of the vegetable oil is lighter than water, so the vegetable oil in the sauce embryo is suspended on the upper layer of the mixed slurry. This is the oil production process of the water substitution method. Therefore, even if boiling water is poured into the shaking pot and mixed with the sauce embryo, it is difficult to keep the temperature of the mixture above 50°C during the oil extraction process. Therefore, for vegetable oils with a low freezing point such as sesame oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com