Vehicle test bench with universality and vehicle headlamp test system

A test bench, universal technology, applied in the direction of testing the alignment of automobile headlights, vehicle testing, machine/structural component testing, etc. Large and other problems, to achieve the effect of high test efficiency and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Below in conjunction with accompanying drawing and specific embodiment of the present invention, the universal vehicle test bench and the vehicle headlight test system will be further explained and illustrated, but this explanation and illustrated do not have any impact on the technical scheme of the present invention. constitute an improper limitation.

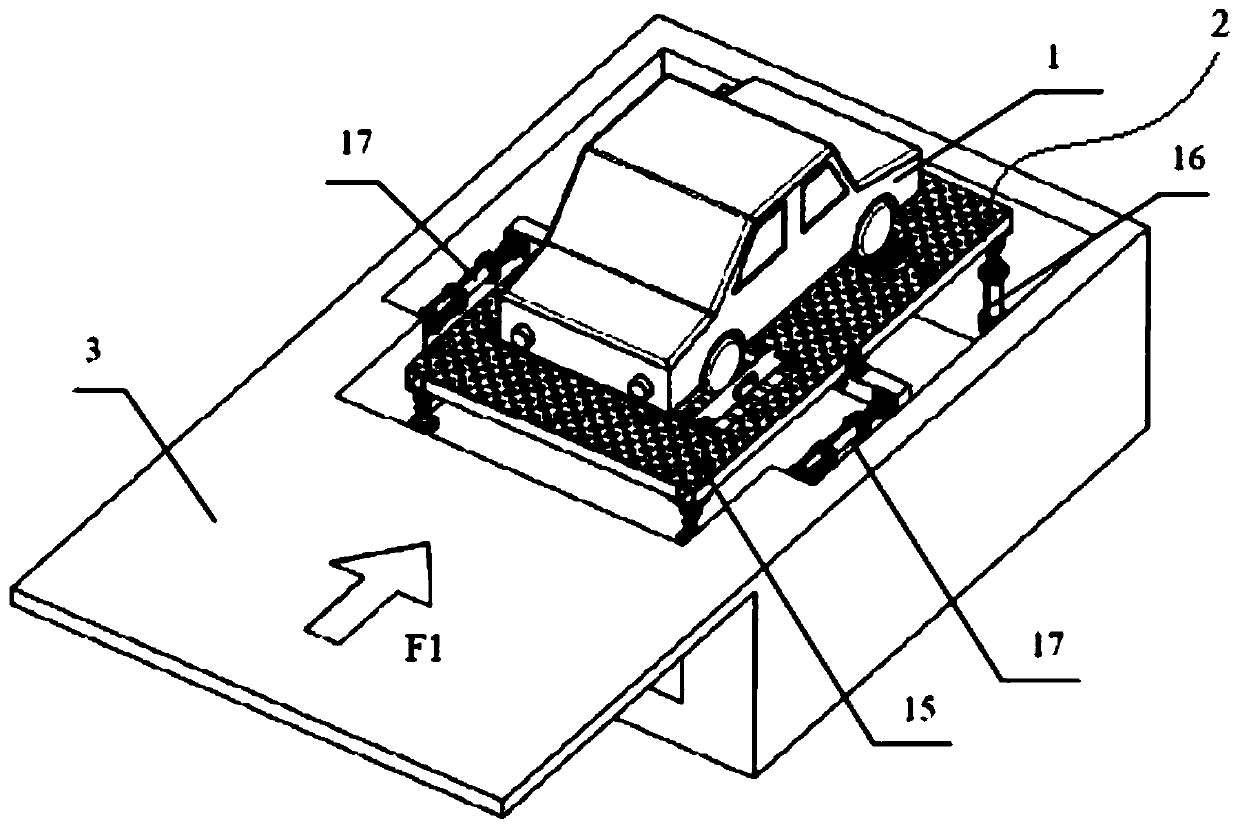

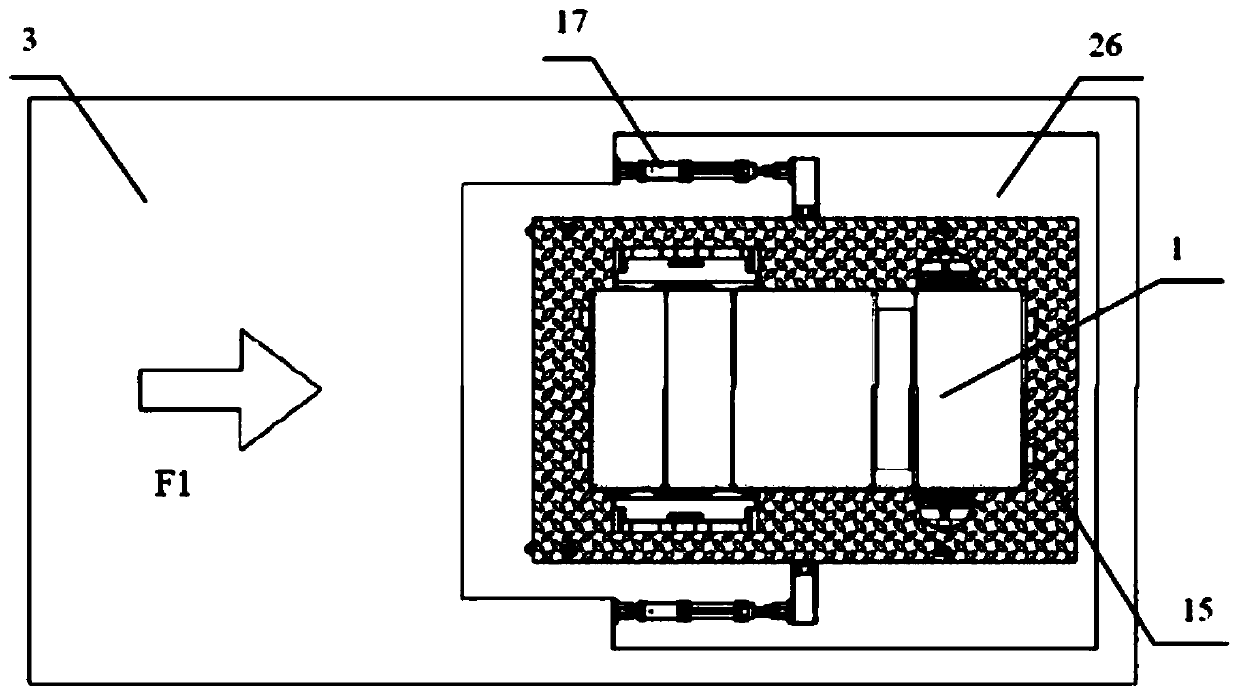

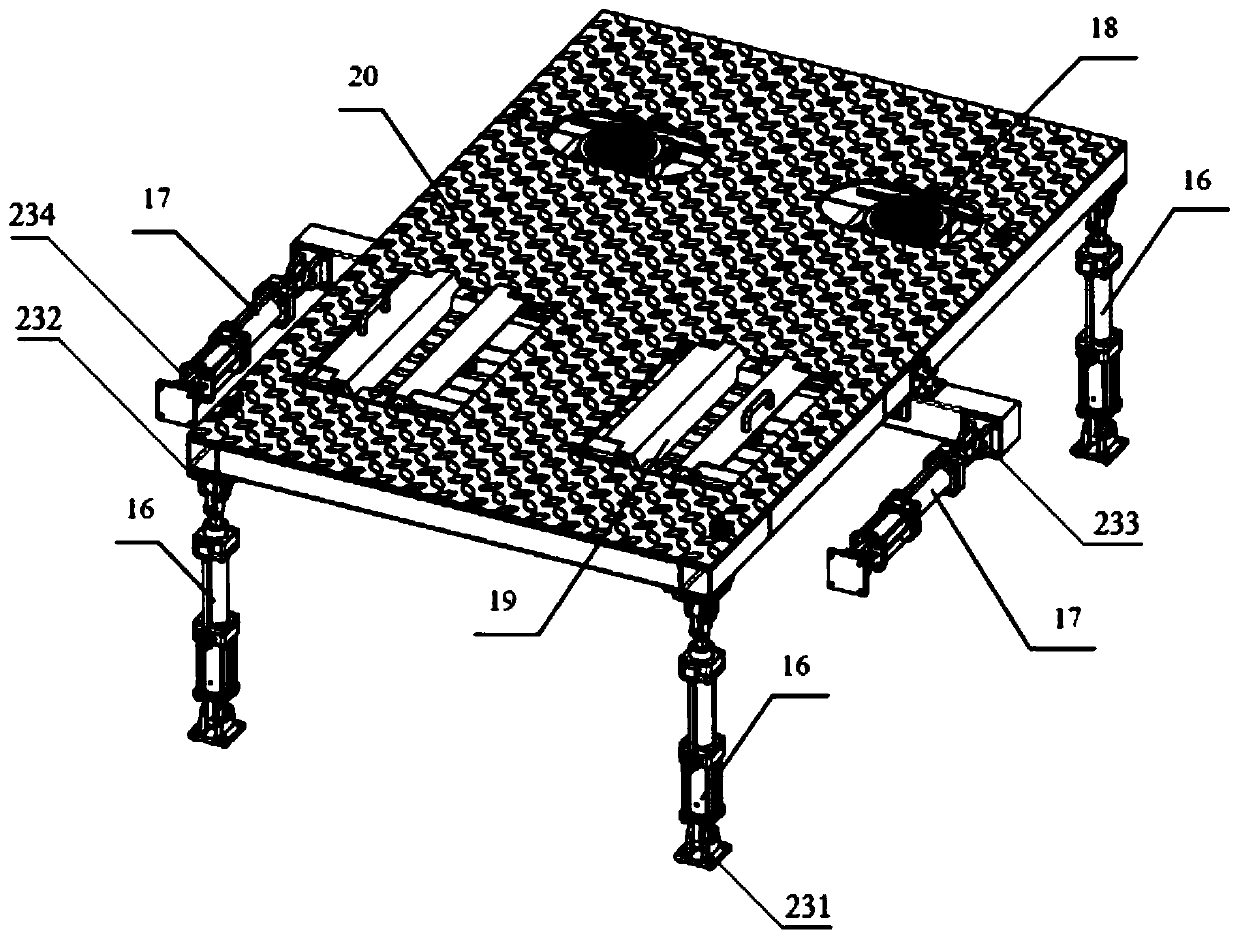

[0085] figure 1 It is an axonometric view of the fixed position of the vehicle test bench in one embodiment of the universal vehicle test bench according to the present invention. figure 2 It is a top view of the fixed position of the vehicle test bench in one embodiment of the universal vehicle test bench according to the present invention.

[0086] like figure 1 shown, and refer to the figure 2 , in this embodiment, the test vehicle 1 drives into the vehicle test bench 2 from the simulated road surface 3 along the driving direction F1 , and the vehicle test bench 2 is set on the steel ground 26 .

[0087] The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com