Test method for crack communication evaluation and heat extraction test of enhanced geothermal system

A test method, enhanced technology, used in the application of stable tension/pressure to test material strength, measuring devices, teaching models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

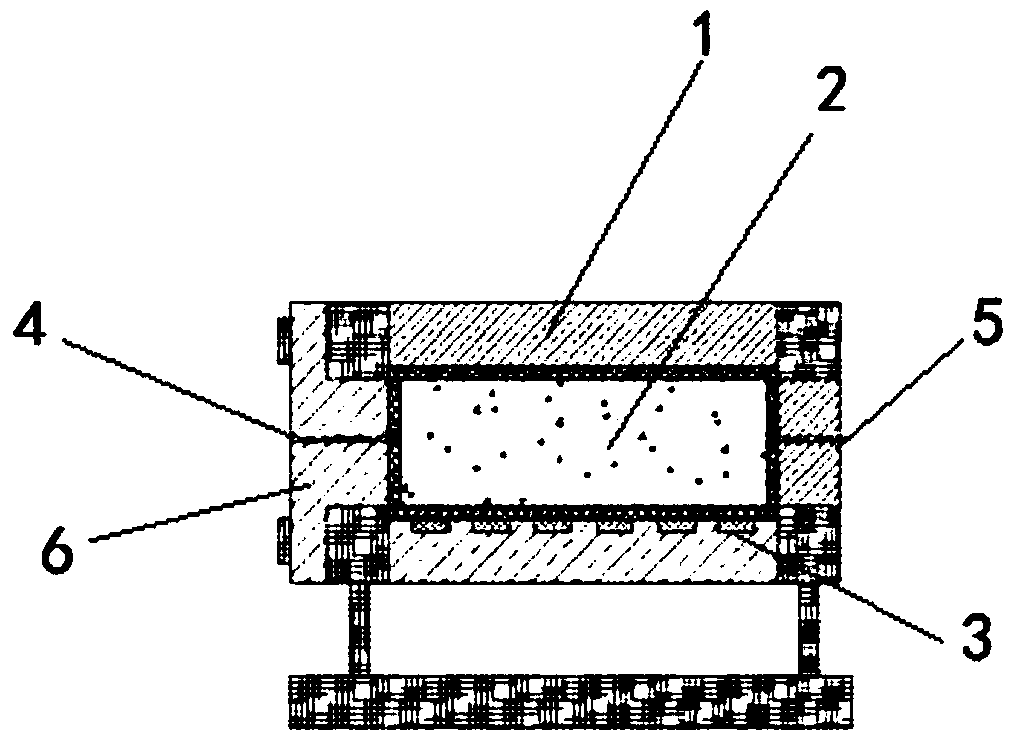

[0046] Embodiment 1 The first mode is used for fracturing, that is, fracturing is performed from one of the first fracturing fluid inlet 4 and the second fracturing fluid inlet 5, and the fractures generated by fracturing from the fracturing fluid inlet are observed In order to simplify the description, the fracturing from the first fracturing fluid inlet 4 is taken as an example for description below; the specific steps are:

[0047] Step 1: Test Preparation

[0048] Take a rock sample 2 of Group A rock sample and put it into figure 1 In the airtight cavity 1 shown, a thermocouple 3 in contact with the rock sample 2 is provided in the cavity 1 for heating the rock sample, and the left and right ends of the cavity 1 are respectively provided with fracturing fluids communicating with the cavity. The inlets are respectively referred to as the first fracturing fluid inlet 4 and the second fracturing fluid inlet 5; the inner ring of the chamber 1 is provided with a gasket to real...

Embodiment 2

[0057] Group B rock samples were taken for the test of Example 2, and Example 2 adopted the second fracturing mode, that is, fracturing from one fracturing fluid inlet, and then fracturing from another fracturing fluid inlet to observe the fracture shape; To simplify the description, first fracturing from the first fracturing fluid inlet 4 and then fracturing from the second fracturing fluid inlet 5 is taken as an example for description. The specific steps differ from the first embodiment only in the fracturing mode, which is specifically reflected in the third step.

[0058] Step 3: Wait until the temperature of the rock sample rises to the set temperature T rock and continue to keep warm for 12 hours, inject from the first fracturing fluid inlet 4 with a constant temperature of T inj The fracturing fluid was continuously loaded at a constant temperature during the injection process. When the injection pressure suddenly decreased and stabilized, the fracturing stimulation w...

Embodiment 3

[0060] Take group C rock samples for the test of Example 3. In Example 3, the third fracturing mode is adopted, that is, simultaneous fracturing from the first fracturing fluid inlet 4 and the second fracturing fluid inlet 5, and the fracture shape is observed. The specific steps It is basically the same as Embodiment 1, except that the fracturing mode of the third step is different, specifically:

[0061] After 12 hours of heat preservation, inject constant temperature from the first fracturing fluid inlet 4 and the second fracturing fluid inlet 5 at the same time inj The fracturing fluid was continuously loaded at constant temperature during the injection process, and the fracturing stimulation was stopped when the injection pressure suddenly dropped and stabilized, and the number of acoustic emission events was recorded; thus, the sample 2 was obtained in the third fracturing mode and the set temperature T rock Fractures formed by fracturing.

[0062] The present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com