A homogenized and subdivided automatic rail-type seed sowing device

A rail-type, homogenization technology, applied in the direction of sowing, planter parts, sowing seeders, etc., can solve the problems of troublesome crop harvesting, too dense sowing, too sparse sowing, etc., to achieve standardized and tidy sowing, improve adaptability, and improve The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

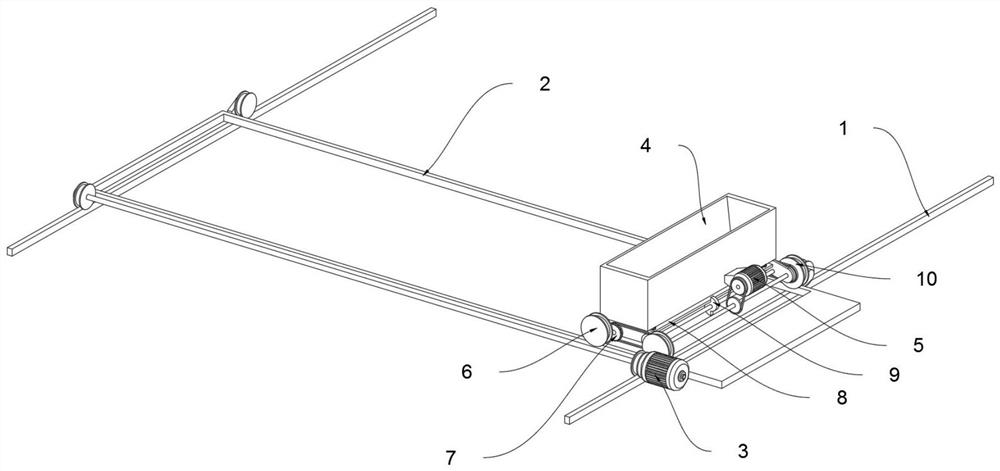

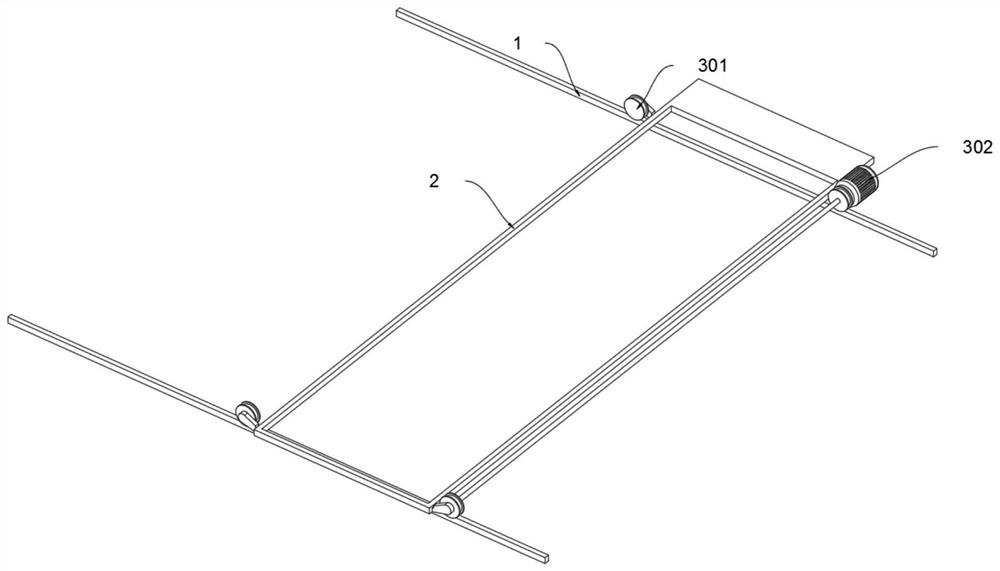

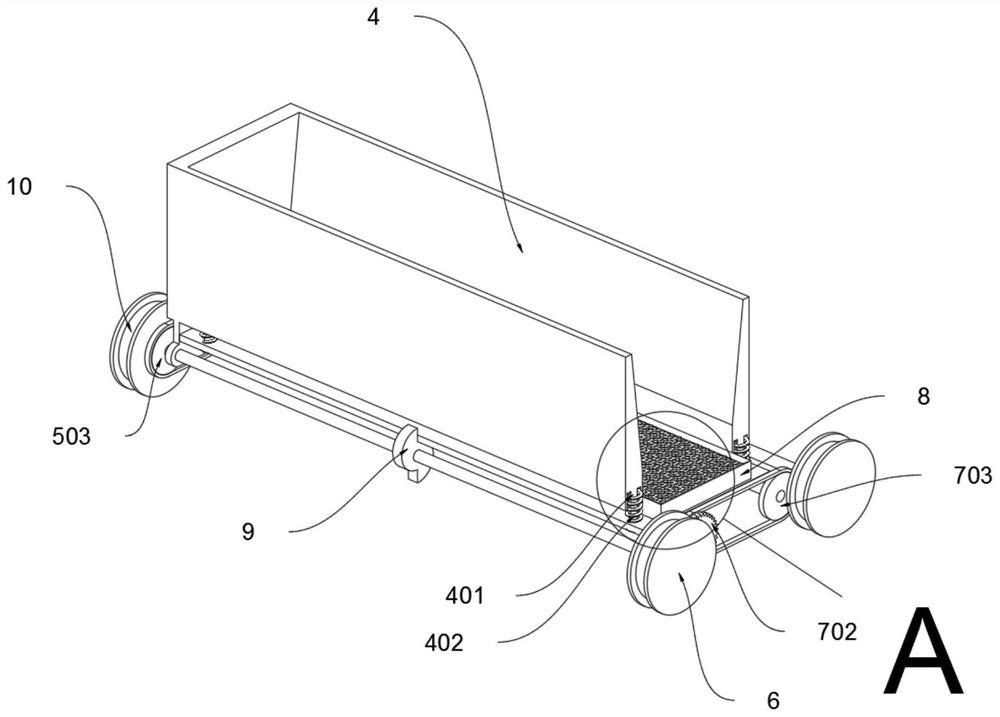

[0034] as attached figure 1 To attach Figure 8 Shown:

[0035] The present invention provides a homogenized and subdivided automatic rail-type sowing seed device, which includes a ground rail 1, a seeding rail 2, a seed trough 4, a driving mechanism 5, a side wheel set a6, a reversing mechanism 7 and a vibrating ring 9; The rail 1 is fixed on the ground for use; the seeding rail 2 is located on the upper part of the ground rail 1, and the seeding rail 2 can move on the top surface of the ground rail 1 through the rail moving mechanism 3; the rail moving mechanism 3 is composed of a moving wheel 301 and a moving motor 302 , and the mobile motor 302 is screwed and fixed on one side of the seeding rail 2 track; the mobile wheel 301 is movably connected around the seeding rail 2; the internal interference of the seed groove 4 is plugged with a grain sieve 8; the driving mechanism 5 passes through The screw is screwed and fixed on one side of the seed tank 4; the drive mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com