Ridge-top-sensing lifting device

A technology of lifting device and induction unit, which is applied in the field of ridge height induction lifting device, can solve the problems of high buckling rate, uneven ridge height, failure to germinate, etc., and achieve the effect of maximizing harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

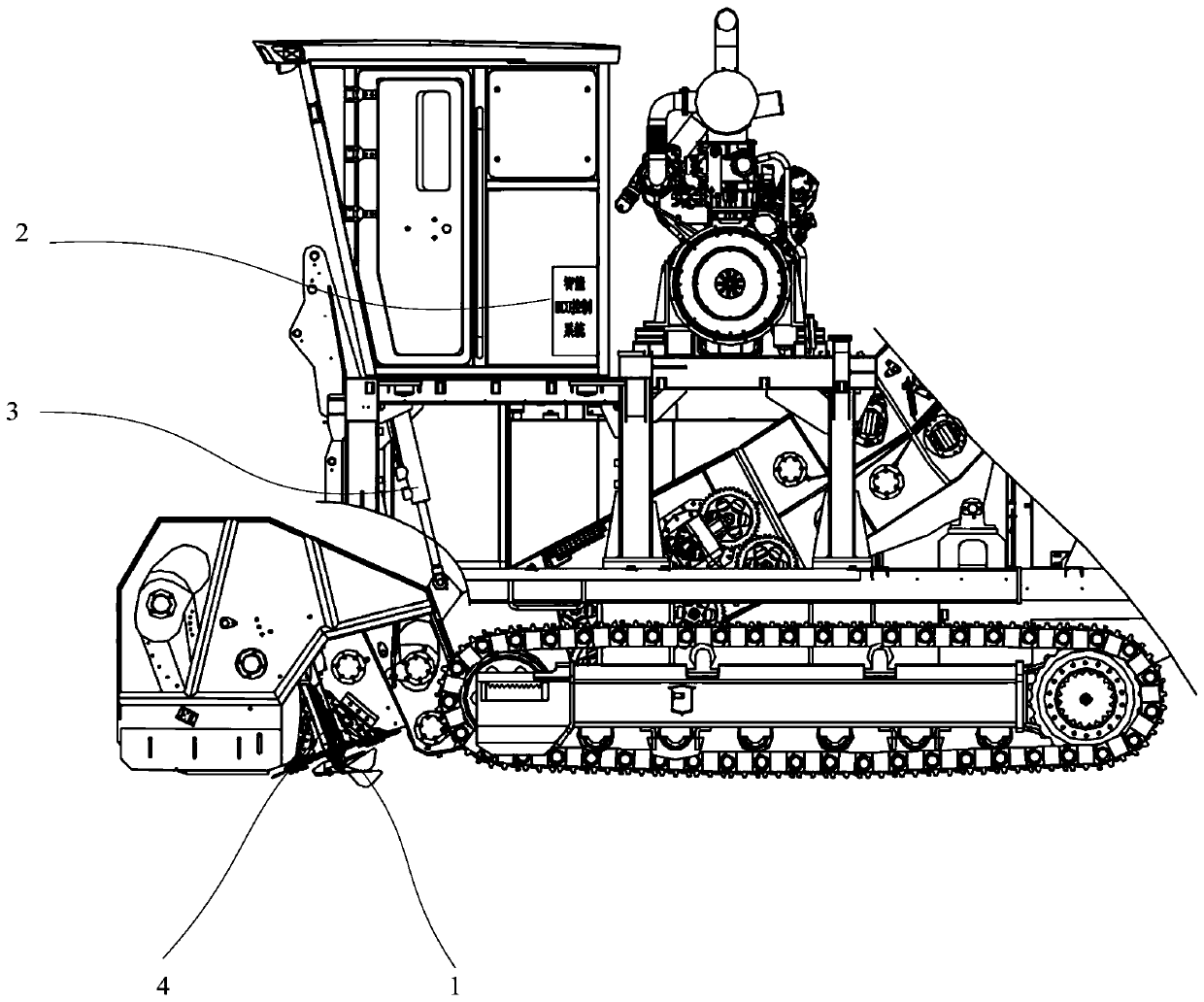

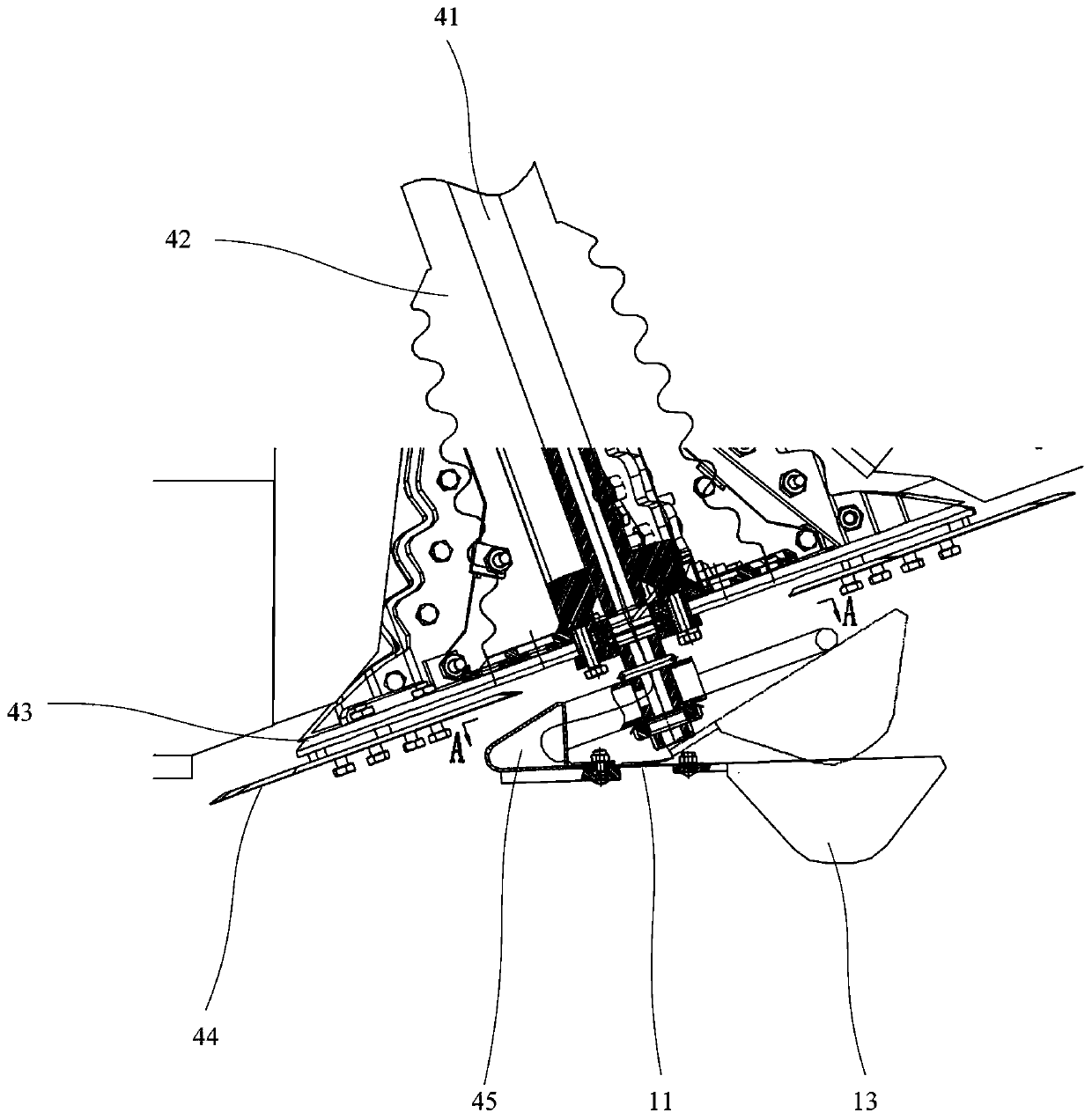

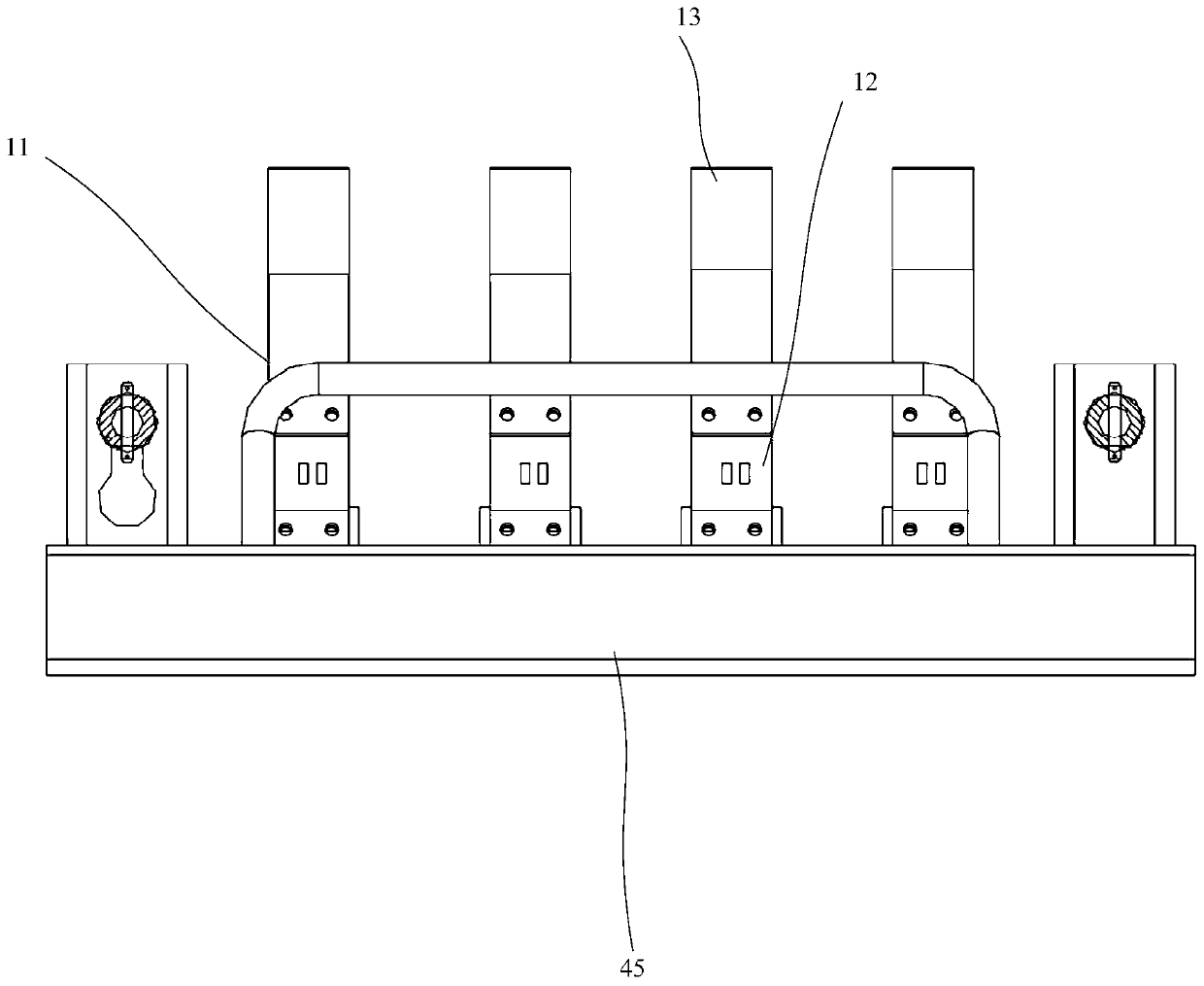

[0009] Introduce the ridge height induction lifting device of the present invention below in conjunction with accompanying drawing:

[0010] Such as figure 1 , figure 2 and image 3 As shown, a ridge height induction lifting device provided by the present invention includes an induction unit 1, an ECU control system 2, a cylinder driver, a lifting cylinder 3 and a cutter assembly 4. Considering that the closer the cutting point of the cutter head is to the cutting point, the induction The more accurate the accuracy of the cutter head control signal can be obtained, and the space at the bottom of the cutter head is extremely narrow, the impact force such as soil is large, the sensing device and the sensor cable must avoid the influence of the rotating cutter head and other factors, the sensing unit 1 is set in At the bottom of the cutter assembly 4, the movable end of the lift cylinder 3 is connected with the cutter assembly 4 to drive the cutter assembly 4 to lift, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com