Homogeneous inflation whipping machine

A homogeneous aeration and whipping machine technology, which is applied to mixing/kneading with additional aeration equipment, dough mixers, structural components of mixing/kneading machines, etc., which can solve problems such as low work efficiency, waste of manpower, and high energy consumption. , to achieve the effect of improving product production quality, improving production efficiency, and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

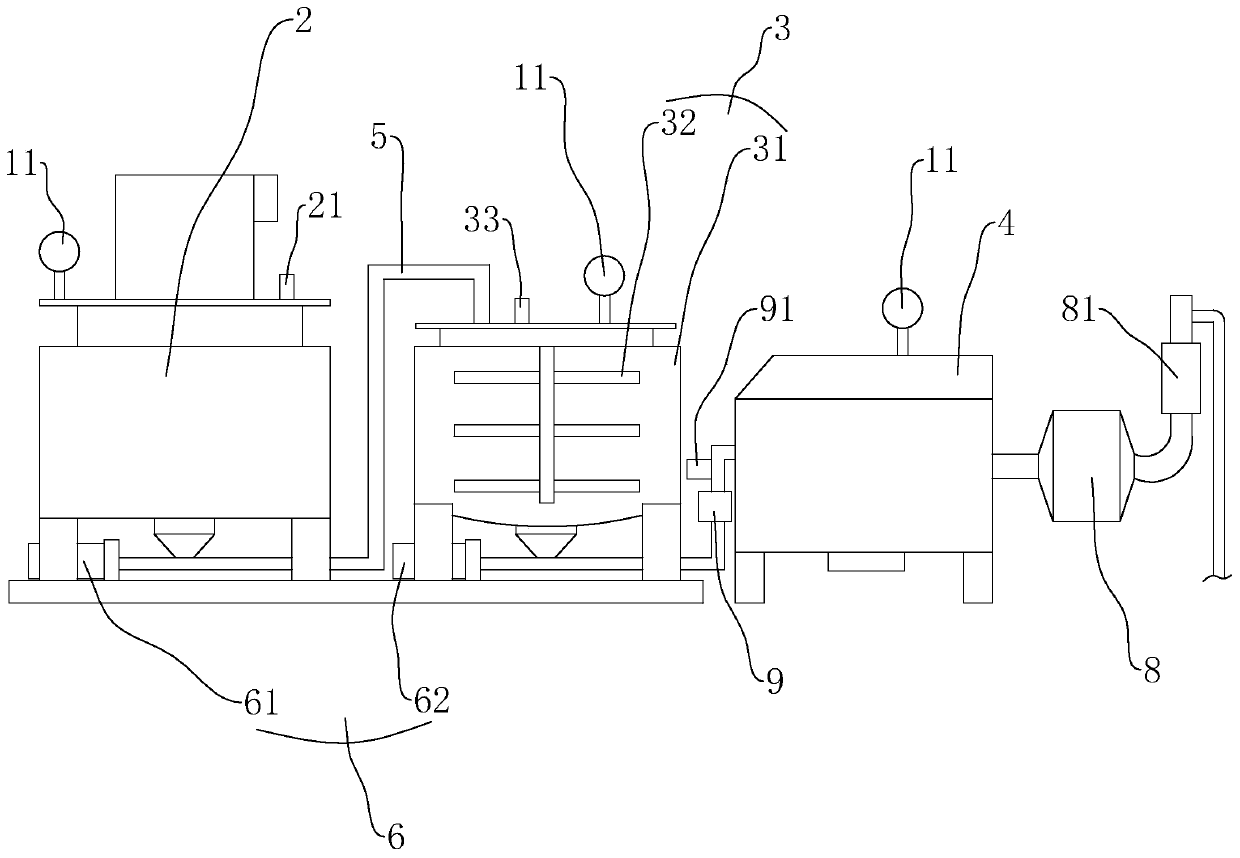

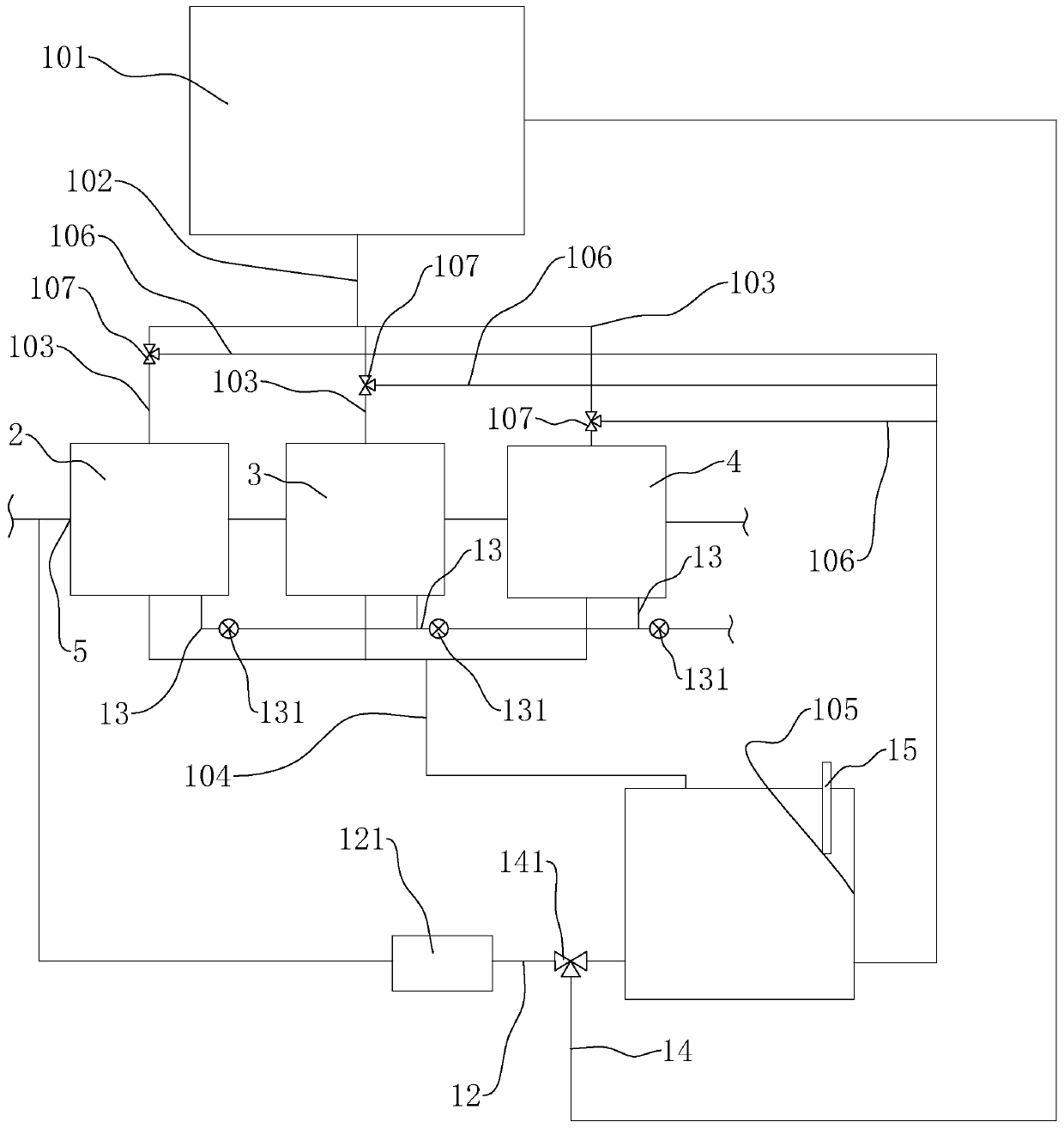

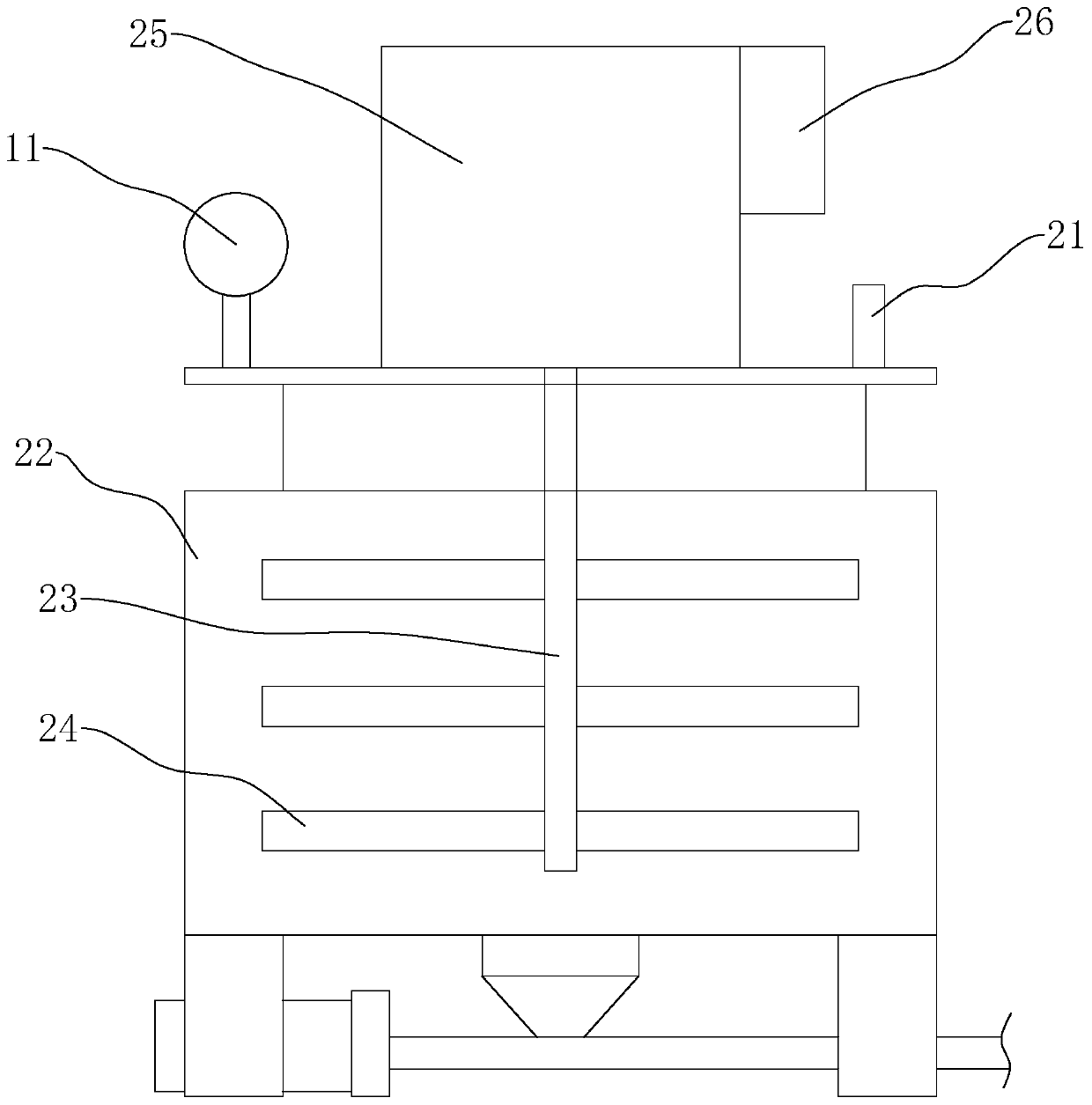

[0029] refer to Figure 1 to Figure 6 Further explanation of the homogeneous aerated whisk.

[0030] A homogeneous aeration sender, such as figure 1 and figure 2 As shown, it includes a control system 1, a material mixing system 2 connected to the control system 1 and sequentially connected through a pipeline 5, a material storage system 3 and a delivery system 4, and a conveying system 6 for conveying materials is arranged on the pipeline 5, thereby The raw materials are mixed by the mixing system 2 and sent to the storage system 3 for storage, and then the mixed materials are sent by the sending system 4, so that mixing, storage and sending are integrated to facilitate production.

[0031] Such as figure 1 and image 3 As shown, the mixing system 2 includes a mixing cylinder 22, a stirring shaft 23 arranged in the mixing cylinder 22, a stirring blade 24 arranged on the stirring shaft 23 and a driving motor-25 connected with the stirring shaft 23, and the driving motor- ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com